Height-adaptive material grabbing manipulator

A technology for grabbing manipulators and materials, which is applied in the field of manipulators and can solve problems such as constant changes in the height of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

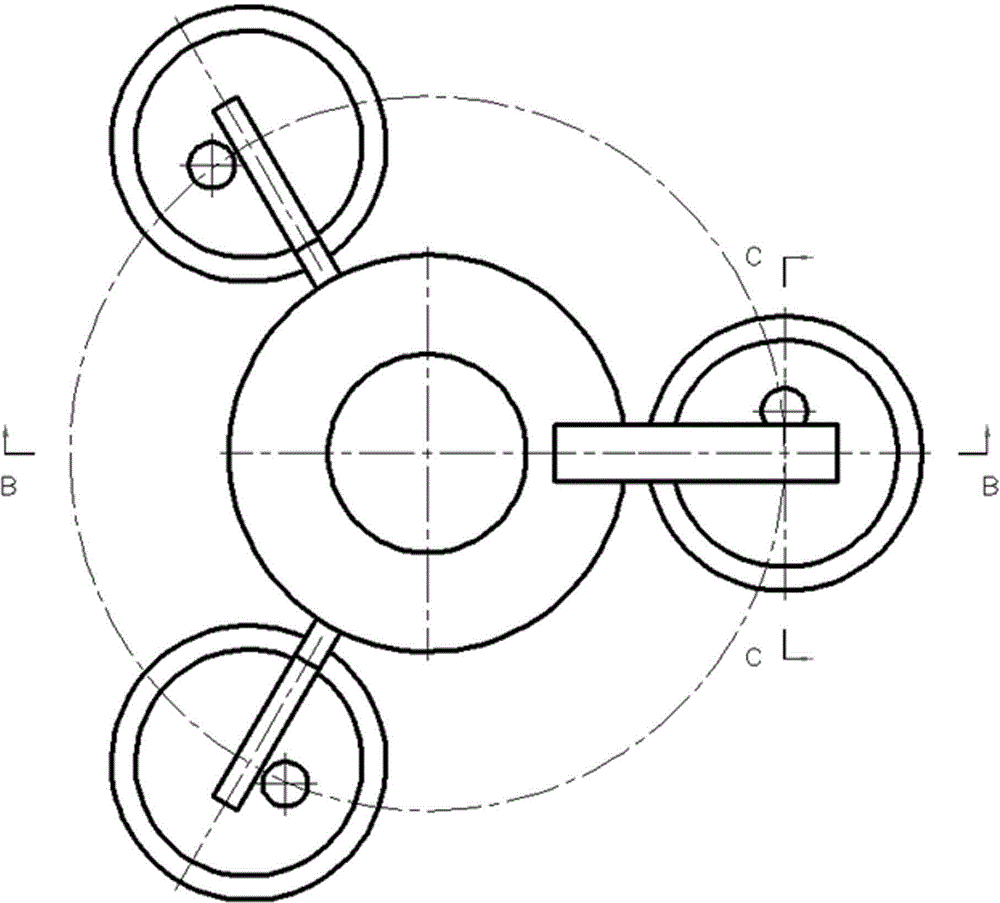

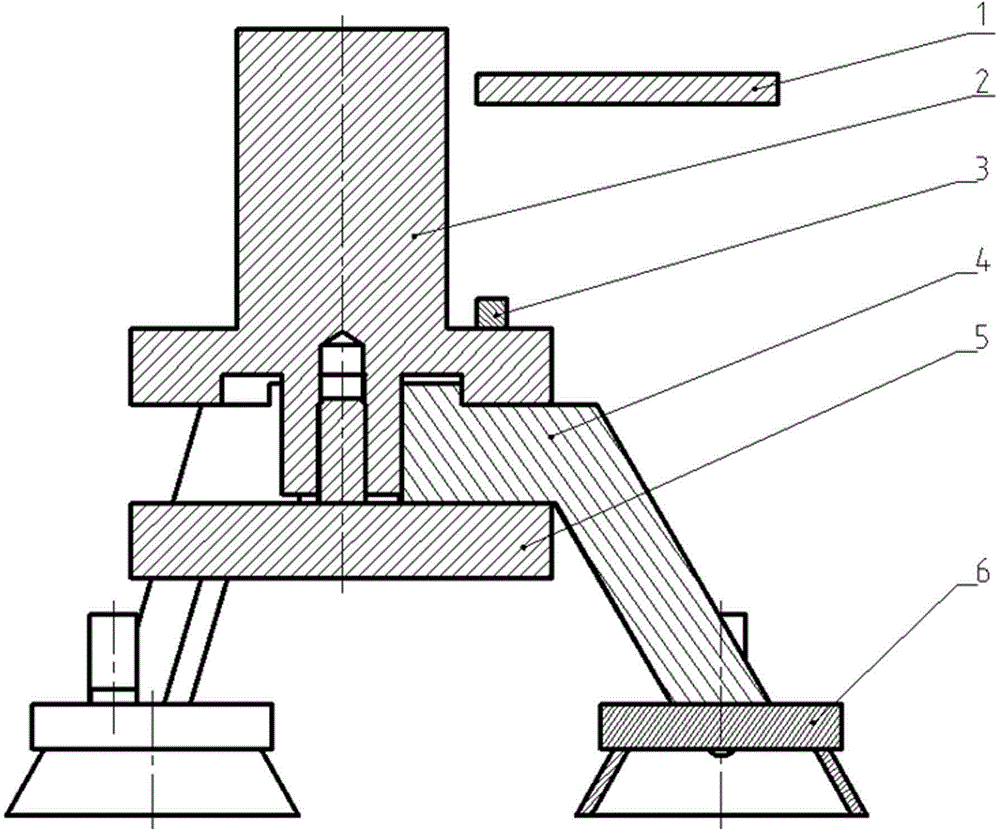

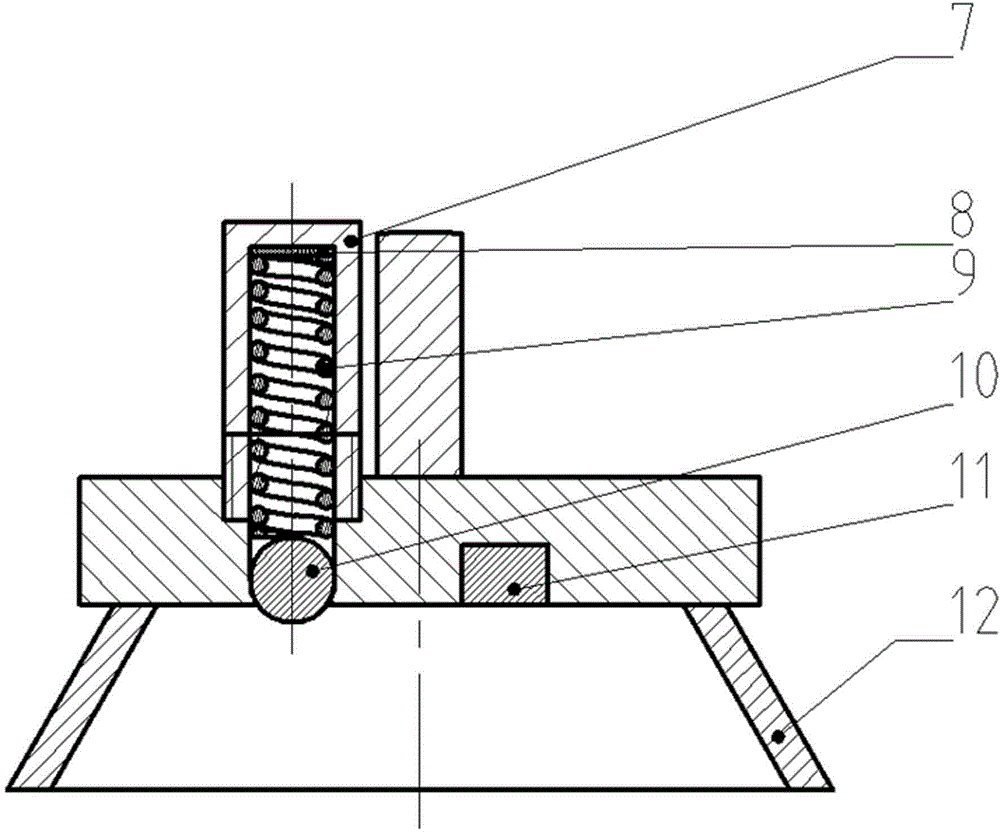

[0016] refer to Figure 1-3 , a material grasping manipulator capable of self-adaptive height in the present invention, consisting of a Z-axis motion shaft 2 and a movable mechanical arm 4 that is movably connected with the Z-axis motion shaft 2 through an adjusting nut 5, and there are 3 movable mechanical arms 4, along the Z axis The shaft movement shaft 2 is evenly distributed in the circumferential direction. According to the maximum position of the grasped material, the position and angle of the mechanical arm 4 are adjusted through the adjustment nut 5. After the adjustment is completed, the nut is tightened to fix the position of the three mechanical arms; to achieve different sizes of materials. Grabbing, when the three mechanical arms 4 are close together, the size of the material to be grabbed is the smallest, and when they are evenly distributed, the size of the material to be grabbed is the largest. The Z-axis motion shaft 2 is connected to the control system to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com