Intelligent well cementing equipment

A technology of intelligent cementing and equipment, which is applied in the directions of wellbore/well components, measurement, sealing/isolation, etc., and can solve the problems of not reaching the right place, not sealing, and not having enough displacement fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

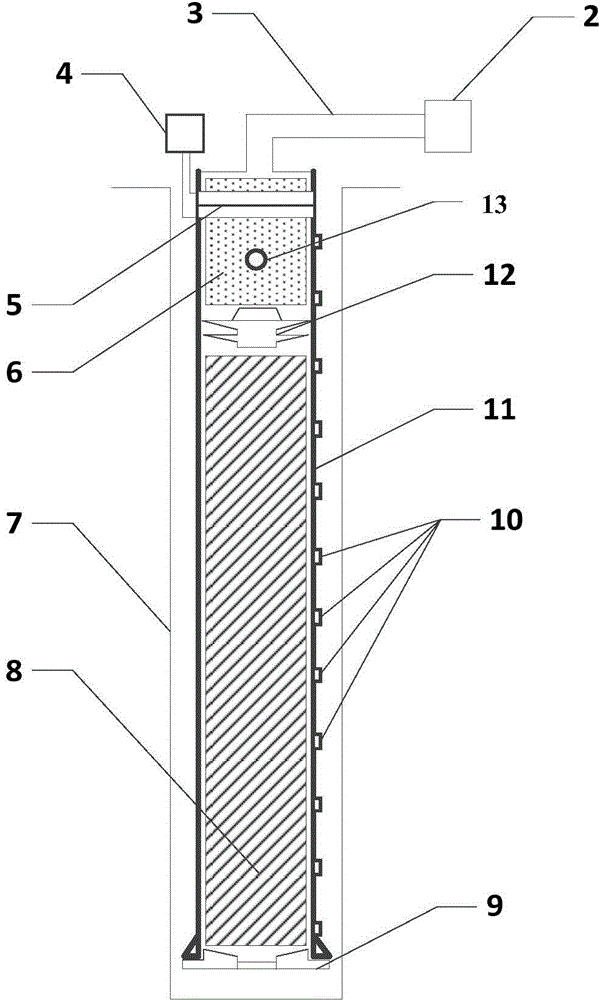

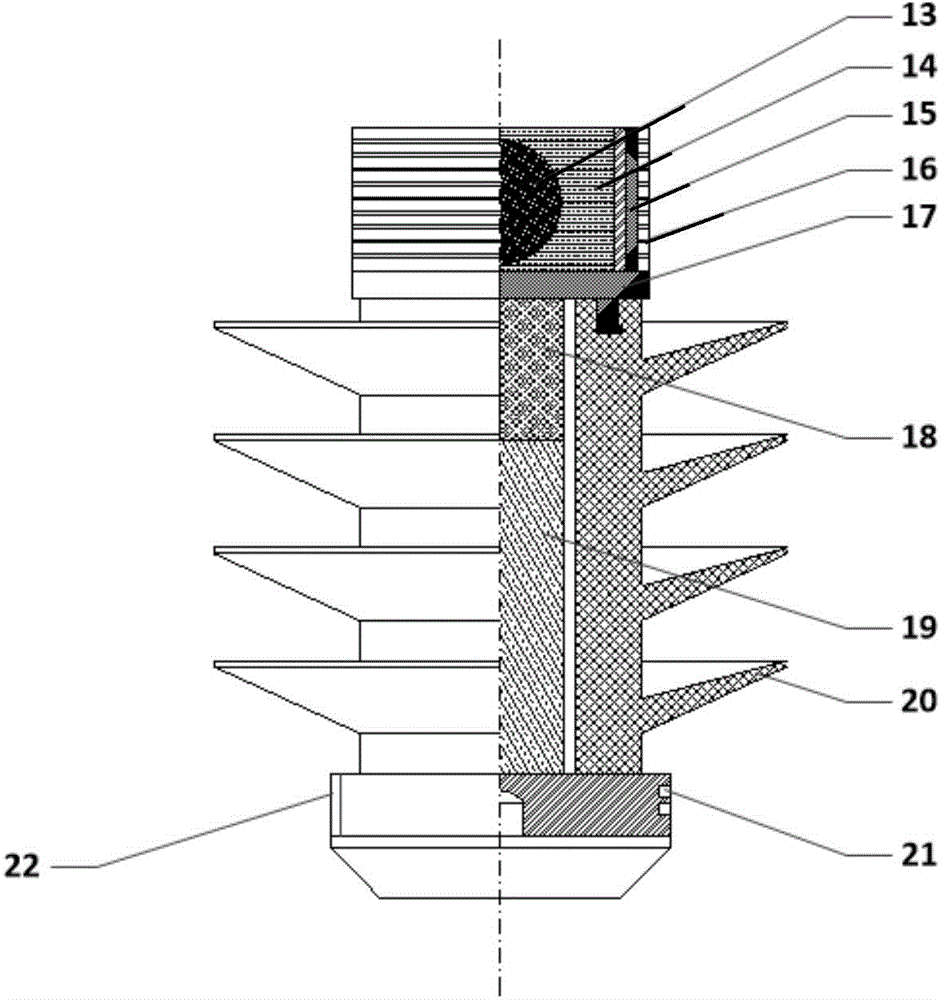

[0019] Such as figure 1 and figure 2 As shown, the intelligent cementing equipment according to the embodiment of the present invention includes a multi-section casing 11 and a rubber plug 12, and the rubber plug 12 includes a rubber disc 20 and a floating ball installed on the rubber disc 20 13. Float ball information writing coil 15, depth information reading coil 16, circuit system 18, wherein:

[0020] Adjacent casing pipes 11 are connected by collars 10, and RFID collar chips storing the depth information of the current collars 10 are installed on the collars 10;

[0021] The floating ball 13 is fixed above the rubber tray 20 by a filler 14, the filler 14 can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com