Deep silicon etching machine and its wafer protection device

A technology for deep silicon etching and device protection, used in microstructure devices, manufacturing microstructure devices, decorative arts, etc., can solve problems such as negative effects of process flow, serrated damage, wafer edge etching, etc., to improve the pass rate , The effect of preventing etching damage and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

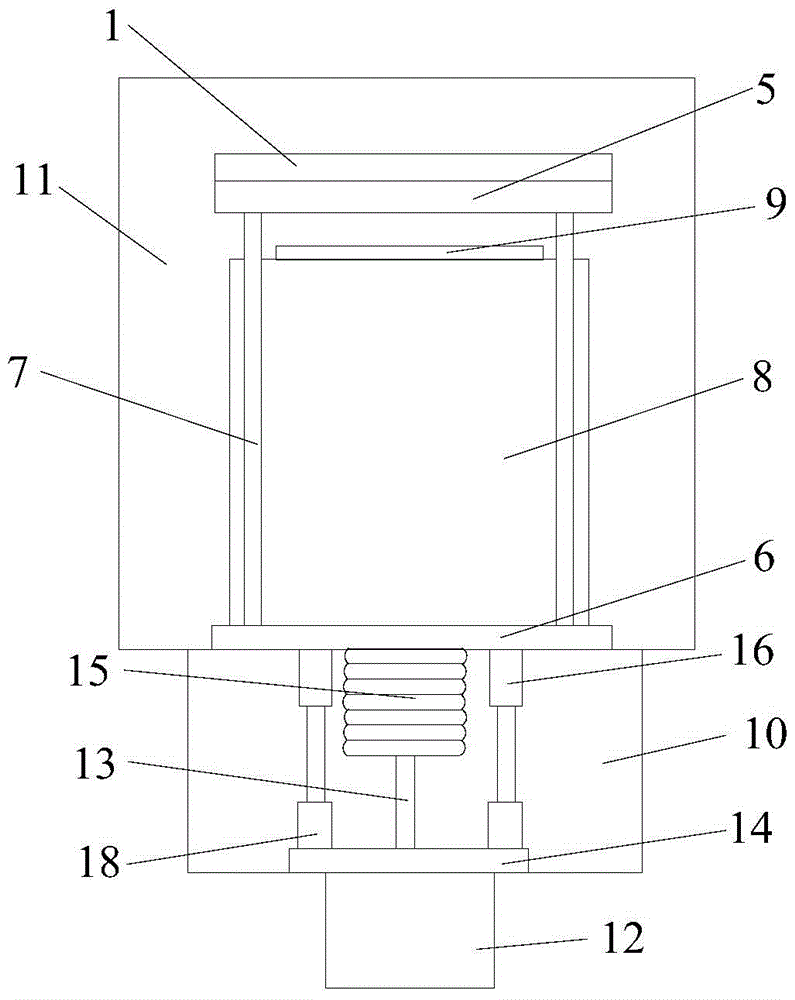

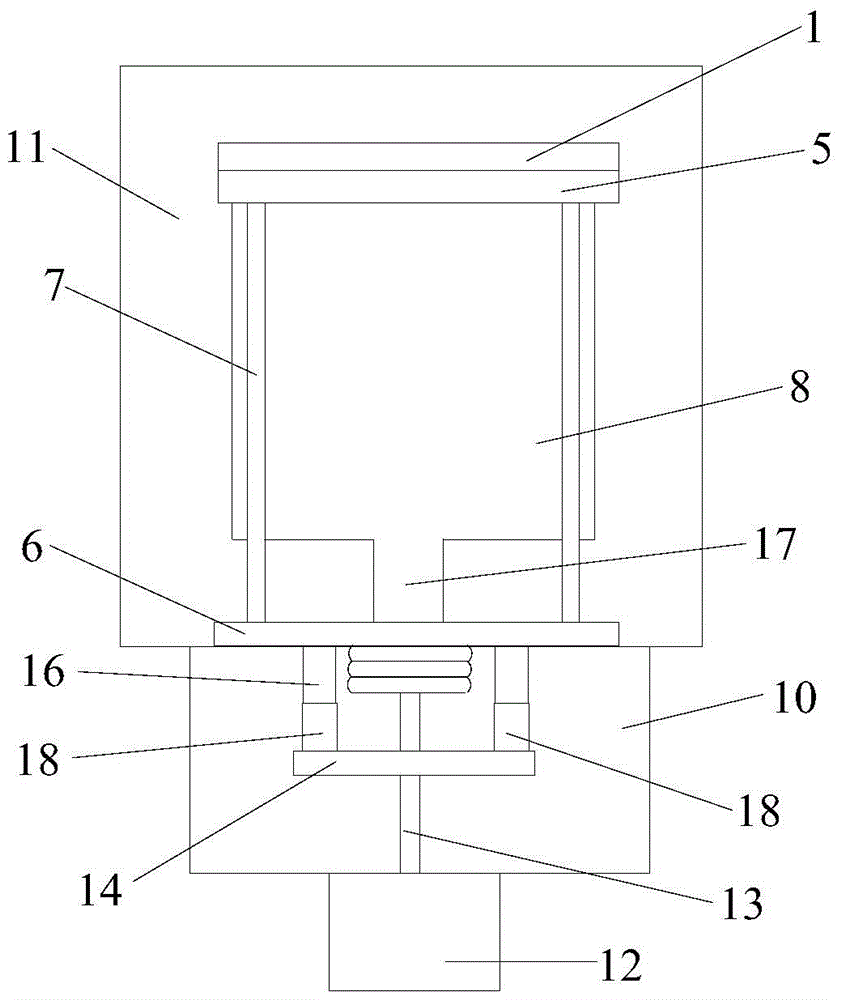

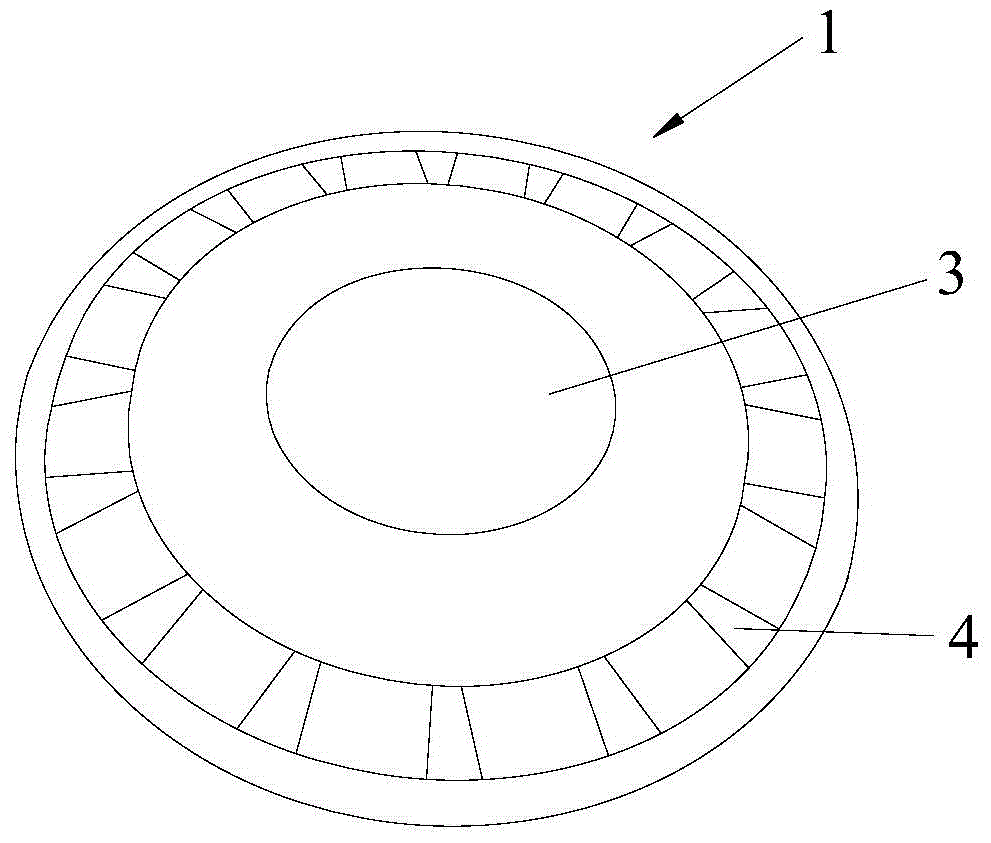

[0023] see Figures 1 to 4 A deep silicon etching machine and its wafer protection device described in a preferred embodiment of the present invention can effectively protect the edge area of the wafer 9 from being damaged by etching during the deep silicon etching process, including Reaction chamber 11, support table 8 arranged in reaction chamber 11, drive chamber 10 arranged below reaction chamber 11, drive device arranged in drive chamber 10, drive device drives support table 8 to move up and down, set in reaction chamber 11 With chip protector. The wafer protection device includes a protection piece 1 and a support piece 2 supporting the protection piece 1 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com