Reversible Axial Fan Blades with Blowing Slots

An axial flow fan and air blowing slot technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as energy loss and increase in manufacturing cost, and achieve reduction of additional energy loss, reduction of manufacturing cost, and complete The effect of improving the pressure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

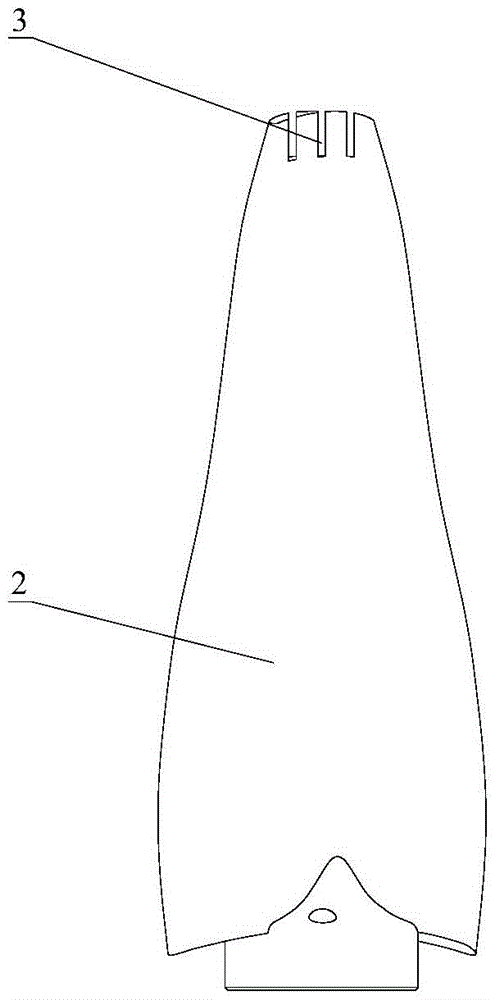

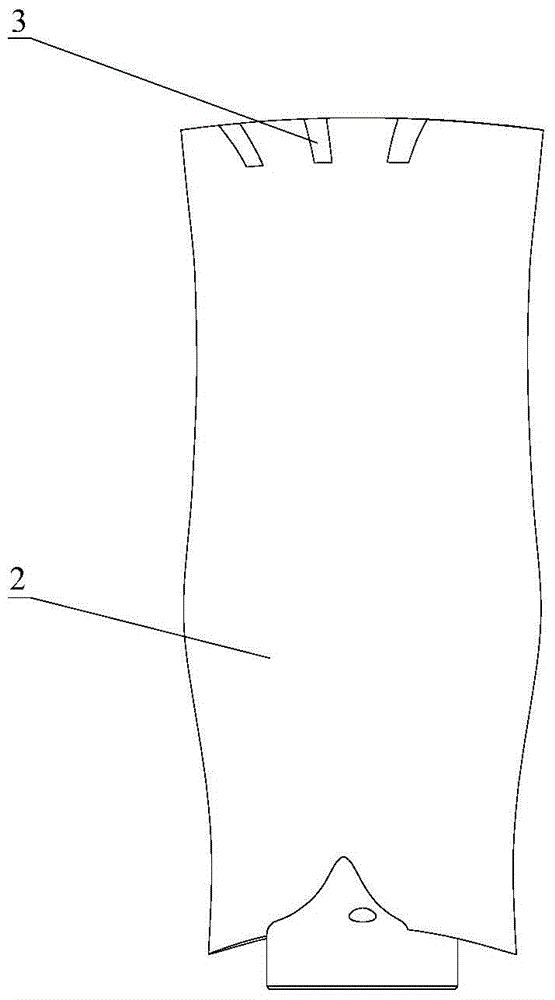

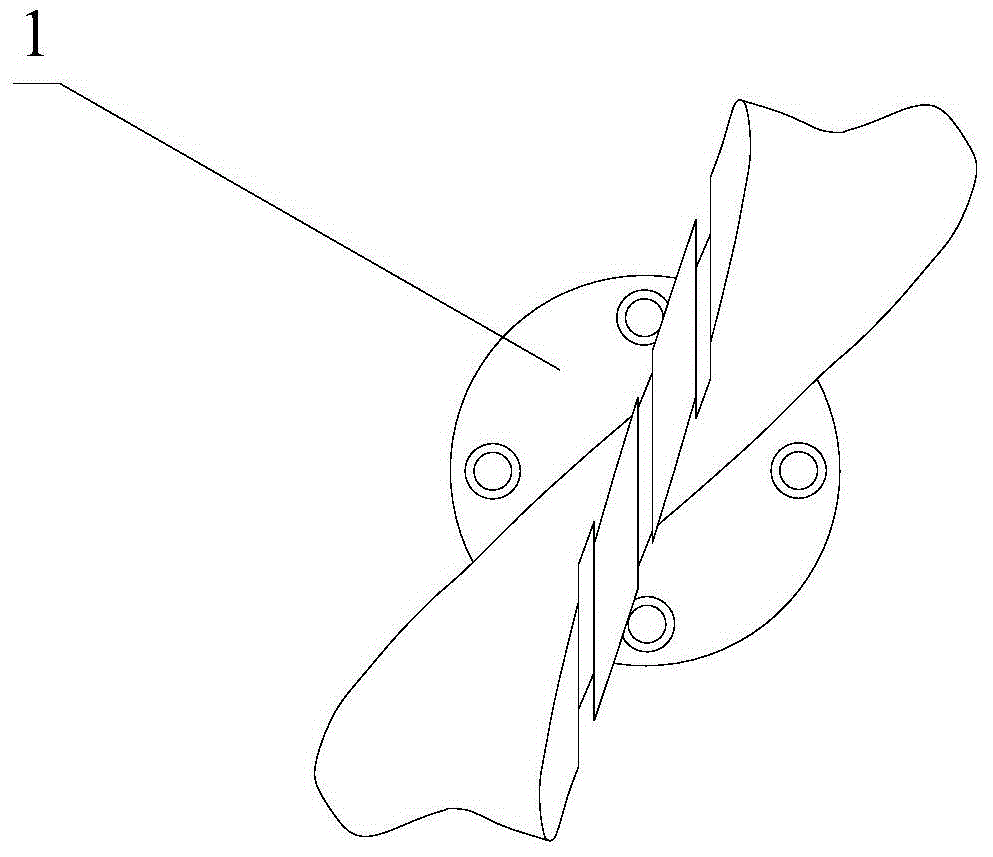

[0031] This embodiment is a reversible axial flow fan blade with air blowing slots, including a petiole 1 , a blade body 2 and an air blowing slot 3 .

[0032] Reversible axial flow fan blades are used for reversible axial flow fans with a diameter of D = 2m. The working speed of the reversible axial flow fan impeller is n = 980r.m.p, and the design flow Q = 60m 3 / s, design total pressure P=950Pa, number of impeller blades Z=10, blade top chord length L=250mm, hub ratio k=0.45. Blade top installation angle β an = 15°.

[0033] Three air blowing slots 3 are opened on the top of the blade of the reversible axial flow fan, and the center line in the width direction of each air blowing slot is in the same direction as the circumferential direction of fan rotation. The blade top is located at the top of the blade body 2 . In this embodiment, there are three air blowing grooves, the width of each air blowing groove is 5.5 mm, and the depth of each air blowing groove is 25 mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com