A Passively Controlled Movable Tiplet Device

A passive control, moving blade technology, applied in engine control parameters, wind turbine control, wind turbines that are consistent with the wind direction, etc., can solve problems such as complex system, increased blade quality, and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

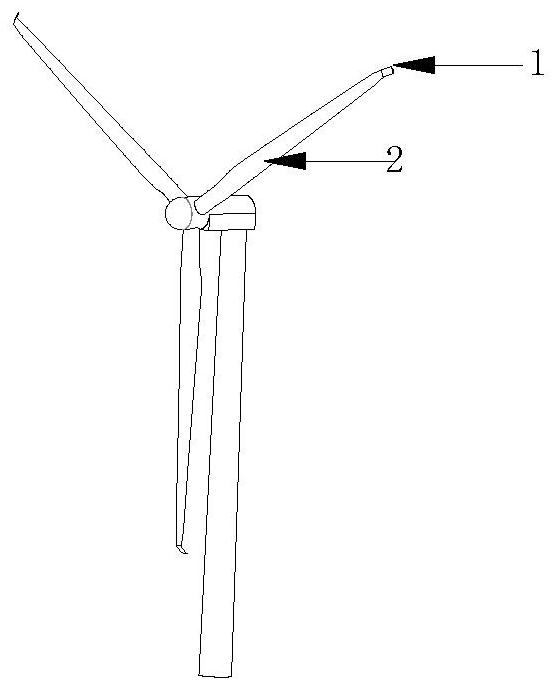

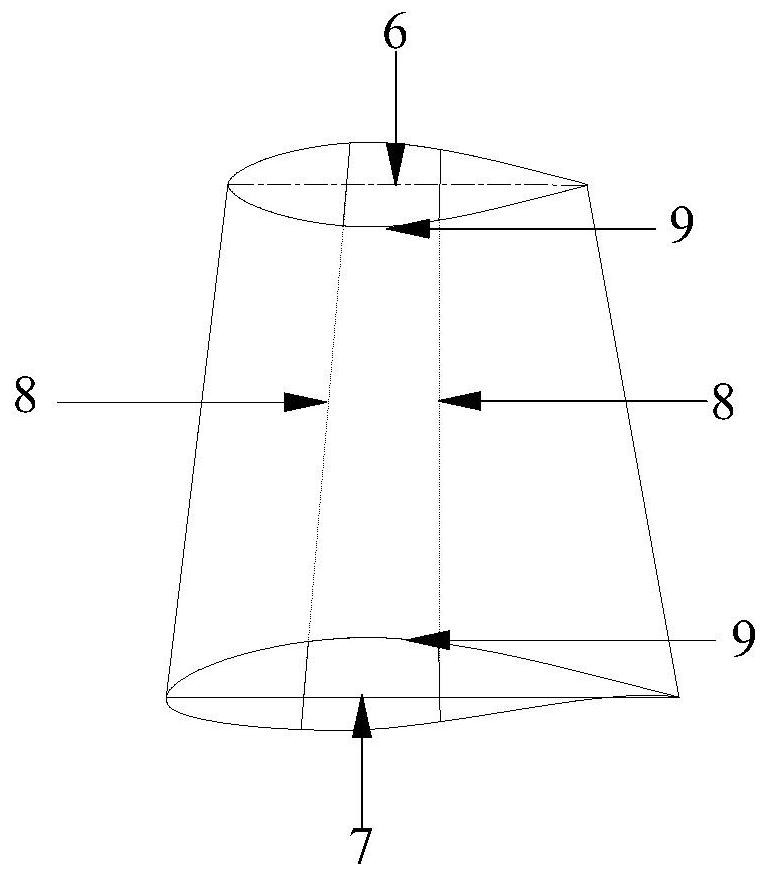

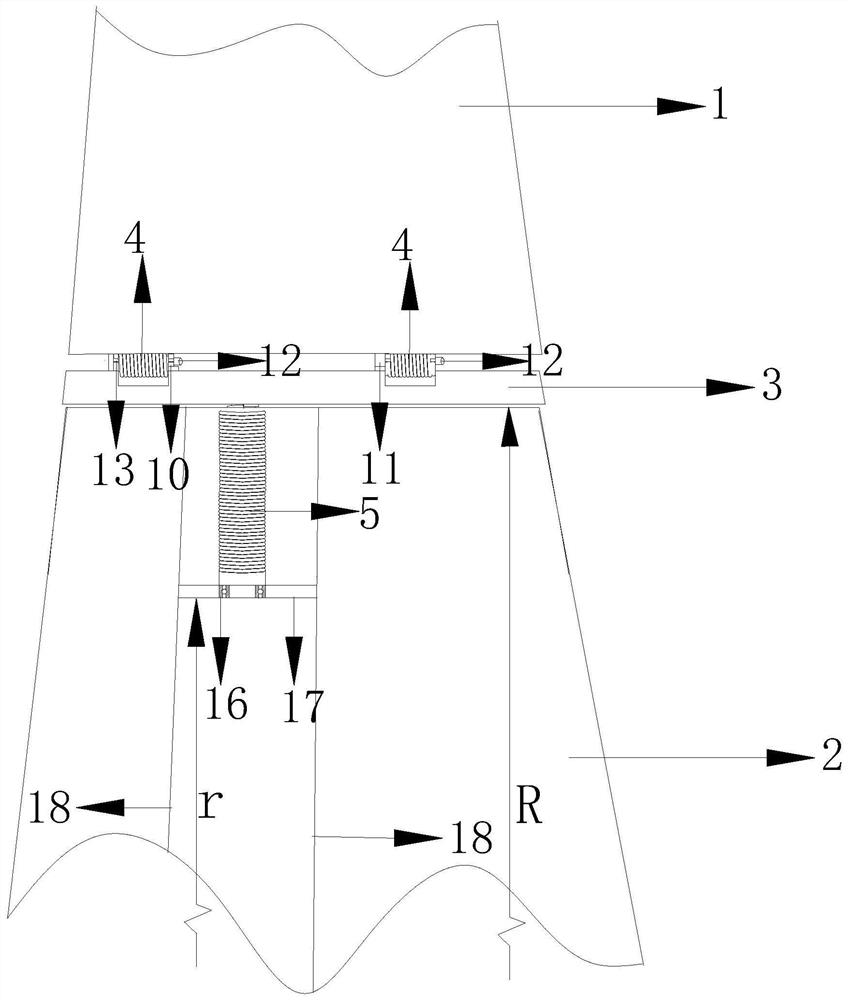

[0020] The present invention consists of winglet 1, blade 2, torsion bracket 3, torsion spring 4, axial spring 5, winglet tip 6, winglet root 7, winglet root web 8, main beam 9, winglet connecting buckle 10, Twist bracket connection buckle 11, torsion shaft 12, winglet locking device 13, axial spring shaft 14, axial spring shaft rotation groove 15, bearing 16, support plate 17, blade web 18, axial spring fixing boss 19 Composition, the specific structure includes blade 2, winglet 1, described winglet 1 is made up of winglet tip 6, winglet root 7, winglet wing root web 8, main beam 9, and described winglet 1 is installed on On the side of the suction surface of the blade 2, an auxiliary mechanism torsion support 3 is provided between the winglet 1 and the blade tip 2, and a torsion spring 4 for controlling the torsion of the winglet 1 is provided between the winglet 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com