A resin-based composite sandwich structure pipe and its synchronous winding manufacturing method

A sandwich structure, resin-based technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high weight increase, low rigidity and easy deformation of resin-based pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

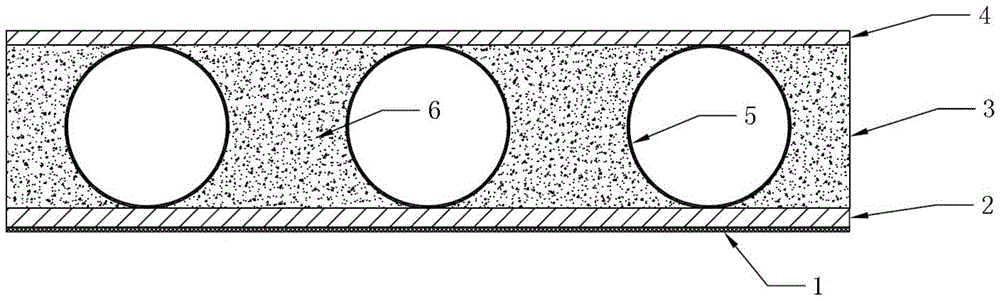

[0025] Refer to attached figure 1 As shown, the resin-based composite sandwich structure pipe of the present invention, from the inside to the outside, is an inner lining layer 1, an inner structural layer 2, a sandwich structure 3, and an outer structural layer 4; wherein, the inner lining layer 1, the inner structural layer 2, the outer structural layer The structural layer 4 is made of resin-based composite material by traditional winding method, and the sandwich structure 3 is prepared as follows:

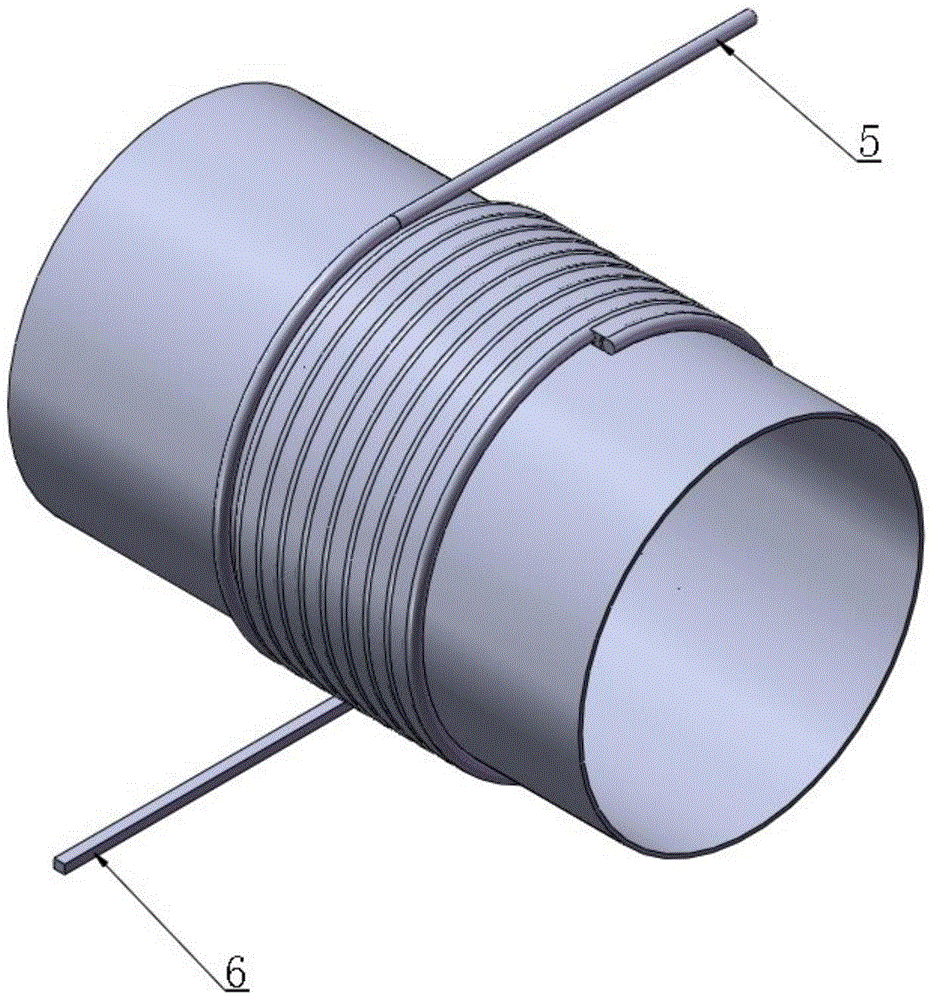

[0026] Refer to attached image 3 As shown, the surface of the inner structure layer is spirally wound to the outer surface of the inner structure layer 2, and the filling material 6 is wound and filled into the gaps between the skeleton structures 5 by spiral winding at the same time, forming A compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com