Spigot joint

A socket joint and socket end technology, applied in mechanical equipment, couplings, etc., can solve problems such as affecting the pipeline structure, instability, fracture interface, etc., and achieve the effect of convenient and durable structure and firm structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

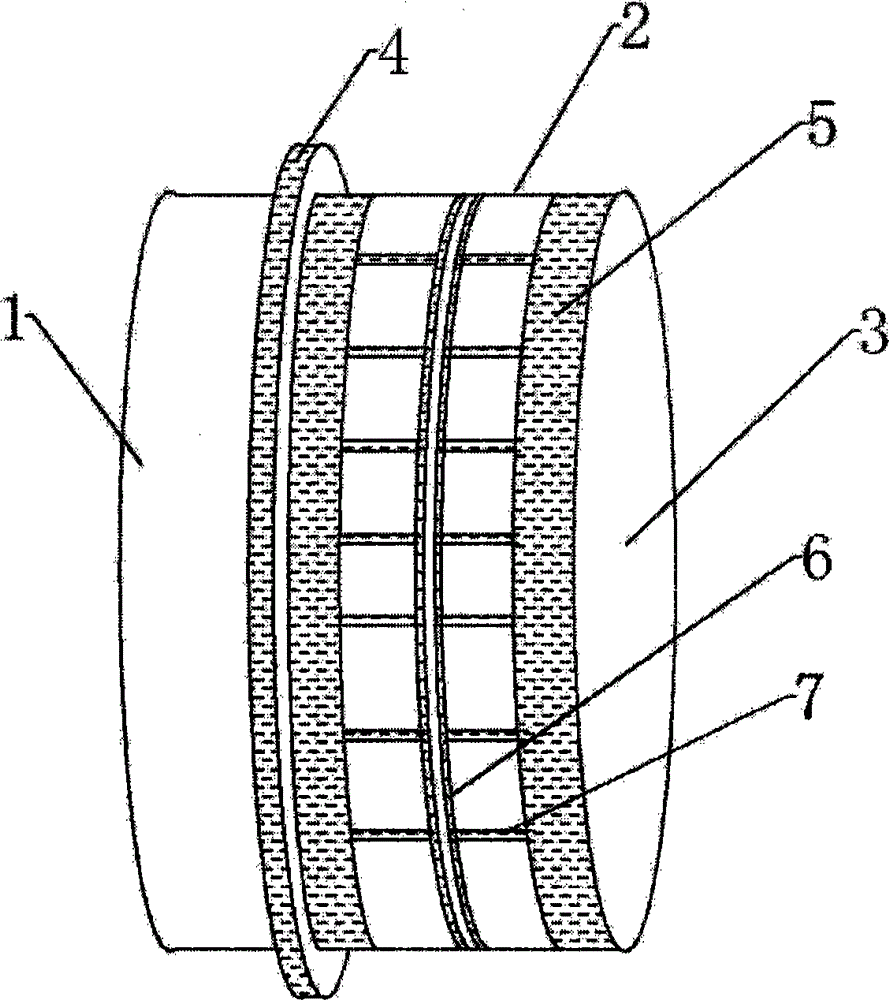

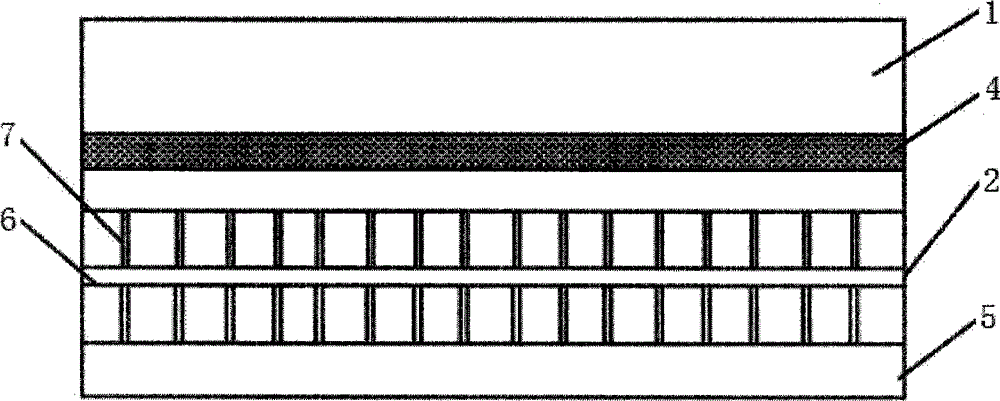

[0014] Such as figure 1 and figure 2 As shown, a socket joint is a ring structure, and the overall structure is made of polyethylene material, including a connection end 1 and a socket end 2. The connection end 1 and the socket end 2 are an integral structure with a smooth inner wall. The connection There is an annular protrusion 4 at the joint between end 1 and socket end 2, and the annular protrusion 4 is inserted into the pipeline at the connection end 1, just coincides with the outer wall of the pipeline, and the connection end 1 and the socket end 2 have a flow hole 3. Both ends of the socket end 2 have annular parts 5 , and two annular reinforcing parts 6 are arranged between the two annular parts 5 . A transverse portion 7 is uniformly arranged between the annular portion 5 and the annular reinforcing portion 6 , and both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com