Conveniently-assembled LED lamp support and LED lamp with same

A technology of LED lamp bracket and LED lamp bead, which is applied to the parts of lighting device, lighting device, lighting auxiliary device, etc., can solve the problem of affecting the contact between the heat dissipation part and the back of the LED lamp bead, the inability to realize the clamping function, and the lack of bracket materials. Elasticity and other issues, to achieve the effect of reducing product defect rate, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

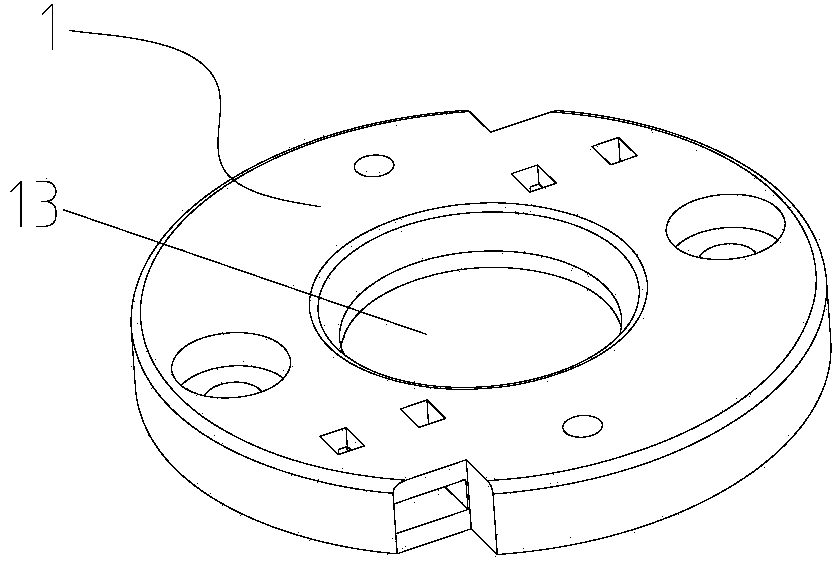

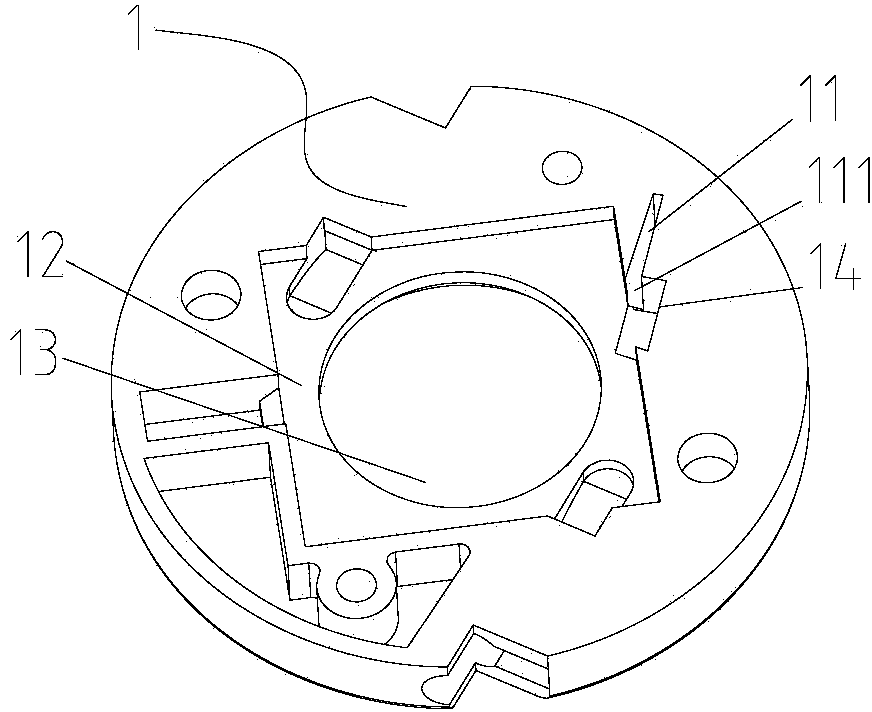

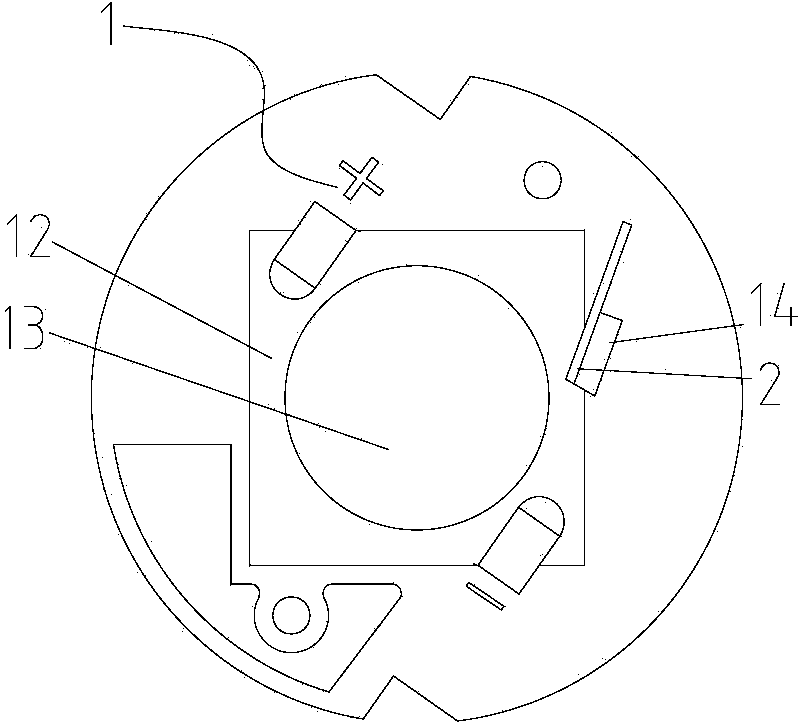

[0031] Such as Figure 1-Figure 5 As shown, in this embodiment, the middle part of the back of the bracket body 1 is an LED lamp bead installation groove 12, and the middle of the LED lamp bead installation groove 12 is a light-transmitting hole 13 for the LED lamp bead 3 to emit light. The LED lamp bead installation groove 12 is rectangular.

[0032] In this embodiment, an installation slot 11 is provided outside the LED lamp bead installation slot 12 , and the installation slot 11 communicates with the inner space of the LED lamp bead installation slot 12 . The installation slot 11 is inserted with a metal shrapnel 2 . An opening is provided between the installation slot 11 and the LED lamp bead installation slot 12, and a notch is also provided on the top.

[0033] In this embodiment, the metal shrapnel 2 is roughly in the shape of a rectangular flat sheet, part of the metal shrapnel 2 is fixed by the installation slot 11, and a part extends from the installation slot 11 ...

Embodiment 2

[0036] Such as Figure 6-Figure 8As shown, in this embodiment, there are two installation slots 11 outside the LED lamp bead installation groove 12 , which are located on the opposite sides of the LED lamp bead 3 . The side of the metal dome 2 can be provided with an elastic joint 21 that spreads out against the side wall of the installation slot 11 to prevent loosening, such as Figure 9 , Figure 10 As shown, after being inserted into the installation slot 11, the elastic engagement portion 21 is in contact with the wall of the installation slot 11 to prevent the metal dome 2 from loosening in reverse. Others are with embodiment 1.

[0037] When assembling the LED lamp including the above-mentioned bracket, first put the back of the bracket body 1 upwards, place the LED lamp bead 3 obliquely into the LED lamp bead installation groove 12, and put pressure on the two metal shrapnels 2 on the two sides respectively. It moves out of the installation space of the LED lamp bead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com