Spray nozzle and cleaning device

A cleaning device and nozzle technology, which is applied to spray devices, spray devices, cleaning hollow objects, etc., can solve the problem that every corner of the side wall cannot be completely cleaned, the cleaning effect is difficult to meet the high requirements of cleanliness in the barrel, and the cleaning efficiency is low. problem, to achieve the effect of simple structure, balanced longitudinal force, and avoidance of barrel shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

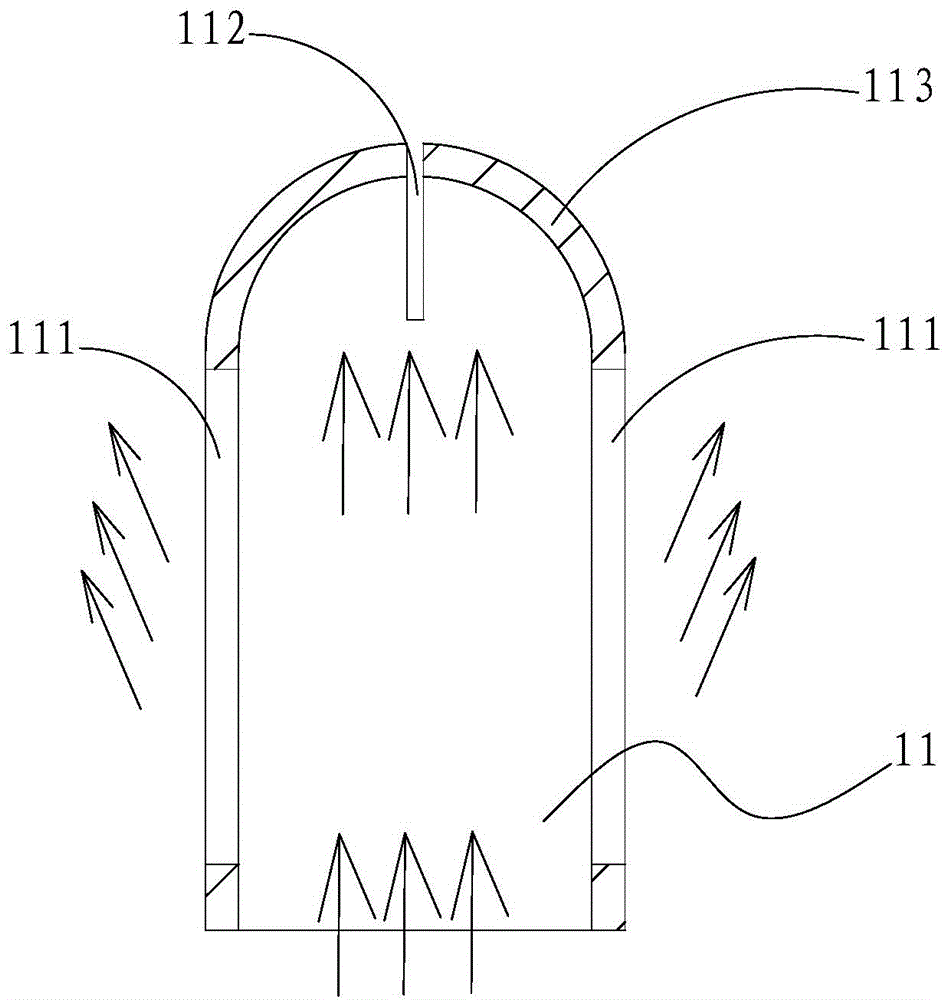

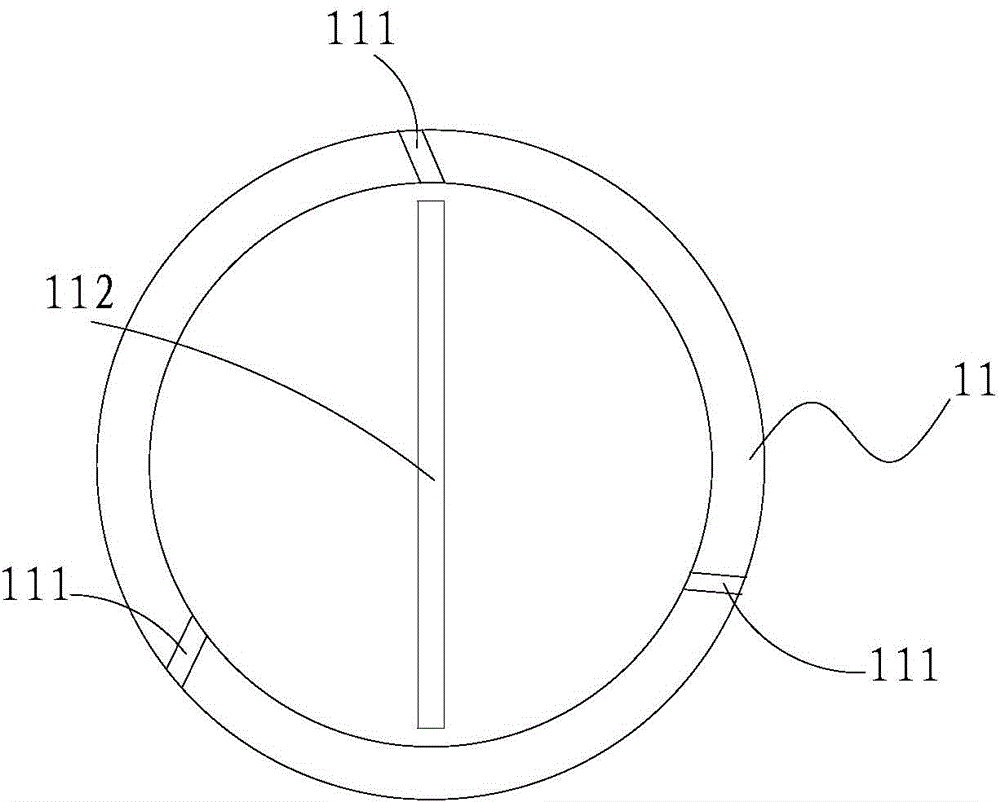

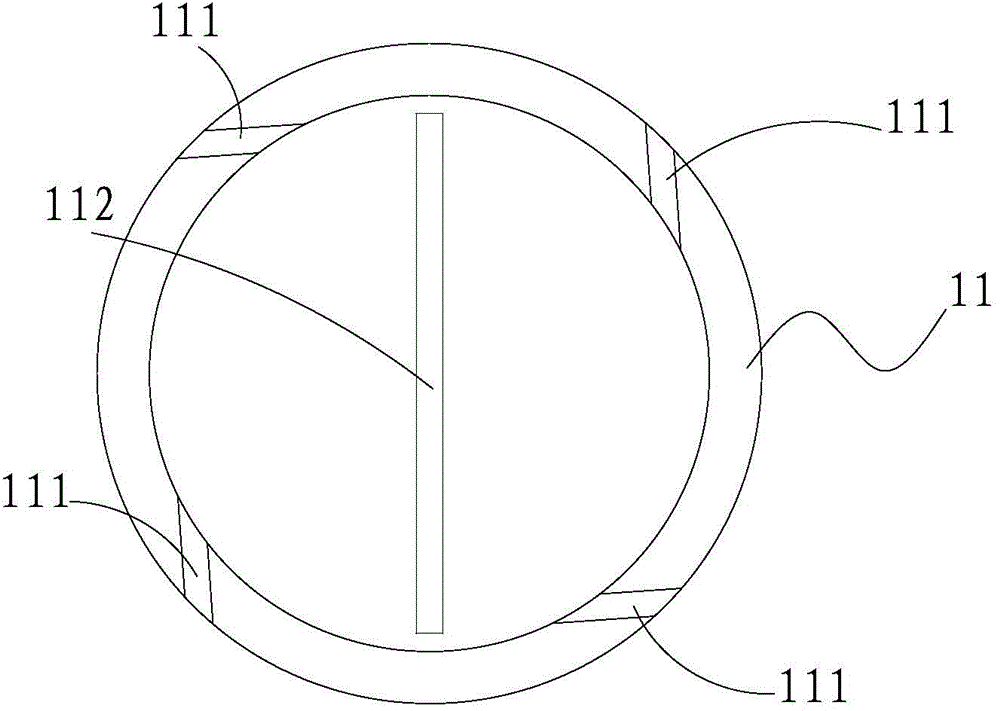

[0028] Such as figure 1 As shown, the nozzle of the present invention includes a nozzle body 11 . One end of the nozzle body 11 is provided with a water inlet (not shown in the figure), and the other end of the nozzle body 11 is provided with a nozzle head. The nozzle head is provided with a strip-shaped water spray port 112 , and the side wall of the nozzle body 11 is obliquely provided with more than three water spray channels 111 .

[0029] In the nozzle of the present invention, since the side wall of the nozzle body 11 is obliquely provided with more than three water spray channels 111, when tap water and the nozzle are used to clean the bucket, the tap water will be sprayed from each water spray channel 111 to the side wall of the bucket. And the spraying direction of the tap water is the same as the direction of the water spraying channel 111 . see Figure 5 , the spraying direction of tap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com