Clamp type drill rod outer wall clamping ring

A technology for clamping rings and drill pipes, applied in workpiece clamping devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of high use cost and high energy consumption of fixing devices, and achieve the effect of avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

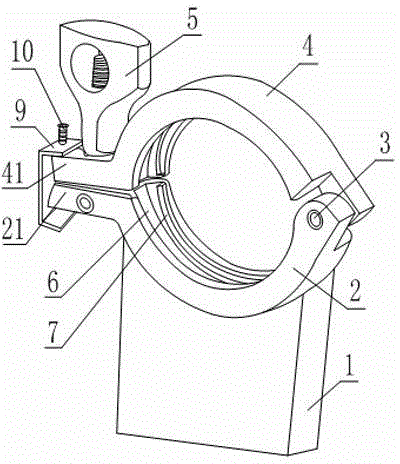

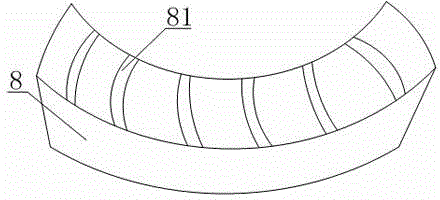

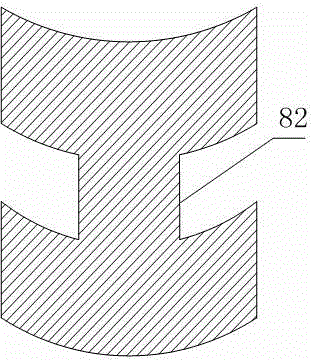

[0019] Such as Figure 1 to Figure 3 As shown, the clamping ring on the outer wall of the clamp type drill pipe includes a fixed seat 1, and the upper end of the fixed seat 1 is provided with a fixed plate I2 with an arc structure, and one end of the fixed plate I2 in the radial direction passes through the rotating shaft 3 and the fixed plate with an arc structure. Ⅱ4 connection, fixed plate I2, the ends of fixed plate I2 are respectively provided with mutual matching convex plate I21, convex plate II41, convex plate I21, convex plate II41 are provided with mutually matching threaded through hole I, threaded through hole II, The threaded through hole I and the threaded through hole II cooperate with the tightening structure 5 provided with the screw rod, the convex plate I21 is connected with the fixed frame 9 through the rotating shaft I, the end of the fixed frame 9 is provided with the screw rod I10, and the convex plate II41 is provided with a The threaded holes matched b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com