A 3D printing mechanism and printing method based on magnetic balls

A 3D printing and printing mechanism technology, applied in the direction of additive processing, etc., can solve the problems of high cost, showing the 3D production process, and not being able to face the audience, so as to increase the 3D sense and reduce the economic burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that the advantages and characteristic effects of the present invention will become more apparent.

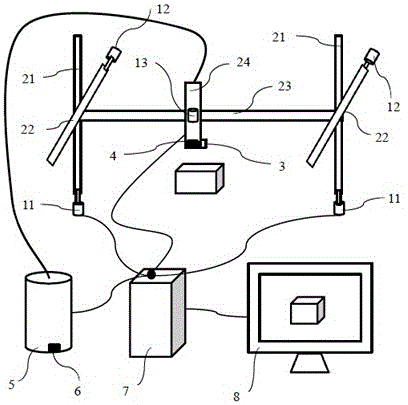

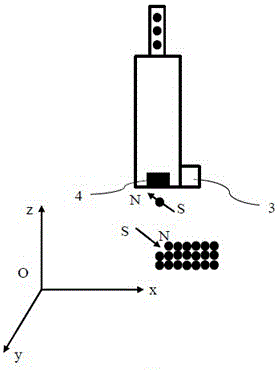

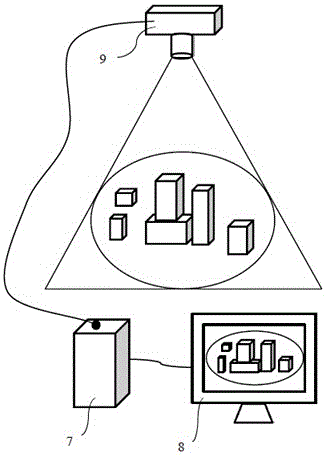

[0021] Such as figure 1 As shown, a 3D printing mechanism based on magnetic beads includes: two first stepping motors 11, two second stepping motors 12, a third stepping motor 13, two first support frames 21, two A second support frame 22, a third support frame 23, a fourth support frame 24, a Hall component 3, a bead magnetization head 4, a bead container 5, a pressure sensor, a data processor 7 and a display terminal 8;

[0022] The first support frame 21 is a screw mandrel, the first support frame 21 links to each other with the first stepping motor 11, the first stepping motor 11 links to each other with the data processor 7, and the two second support frames 22 are respectively installed on two first On the support frame 21, the data processor 7 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com