vehicle floor structure

A vehicle and floor technology, which is applied in the field of floor structure, can solve the problems of adverse effects on the layout of surrounding components, increased weight, and reduced compartment space, and achieves the effects of improving rigidity, increasing bearing load, and restraining bending deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

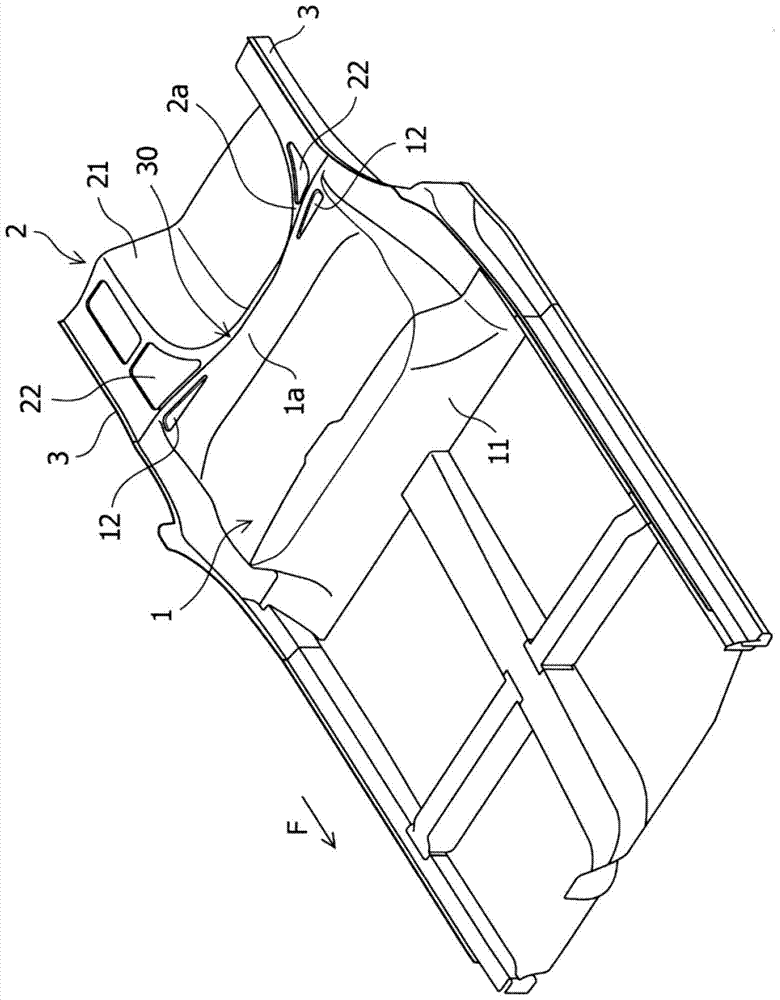

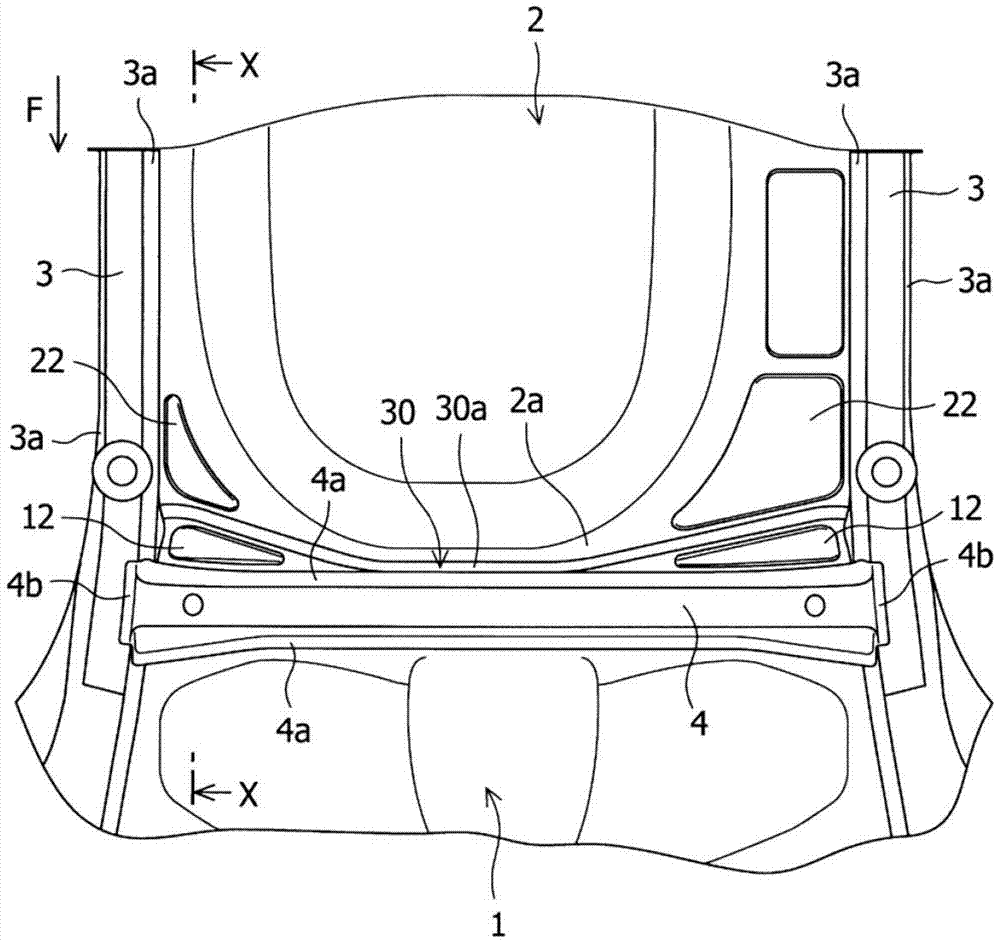

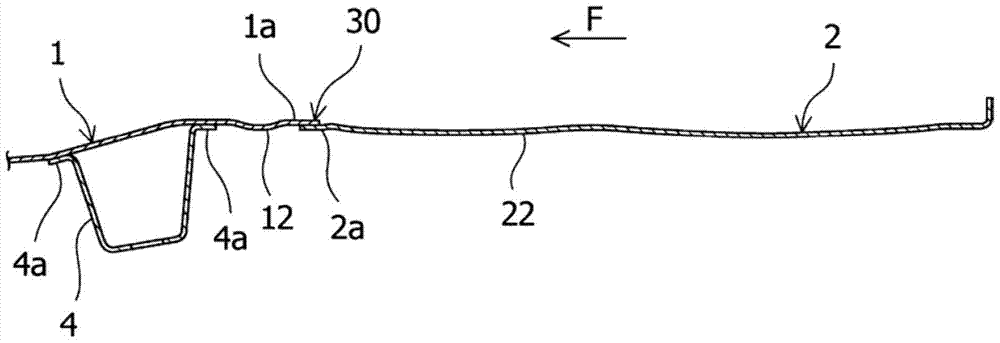

[0027] Figure 1 ~ Figure 4 The floor structure of the vehicle which shows embodiment of this invention. and, in Figure 1 ~ Figure 4 In , the arrow F direction indicates the front of the vehicle.

[0028] Such as Figure 1 ~ Figure 4 As shown, the floor structure of the vehicle according to the embodiment of the present invention has a front floor (combined by combining relatively independent front outer panels and center panels) 1 and a rear floor 2 arranged along the front-rear direction of the vehicle. That is, in the floor structure of the present embodiment, the rear end 1a of the front floor 1 extending from the vehicle front to the vehicle rear and the front end 2a of the rear floor 2 extending from the vehicle rear to the vehicle front are joined by spot welding in a state where they overlap up and down. Together, the joining surface part 30 is formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com