Self-loading compression pull arm carriage

A compression type and carriage technology, which is applied in the direction of transportation, packaging, garbage storage, etc., can solve the problems of low efficiency of oil cylinder output mode, easy wear and tear of slider, and difficult replacement, so as to achieve large use space, avoid corrosion, and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to introduce the present invention in more detail, the present invention will be further described below in conjunction with the accompanying drawings.

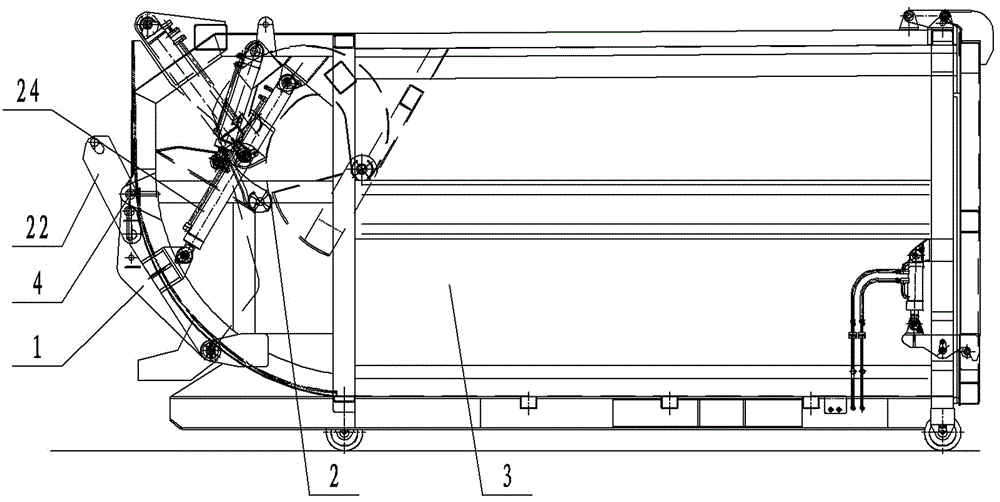

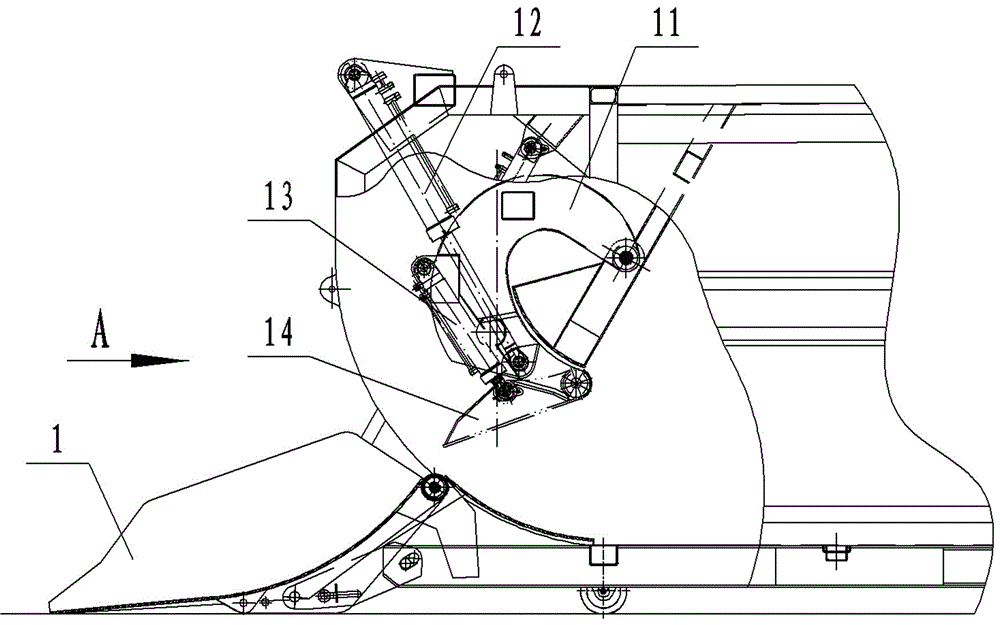

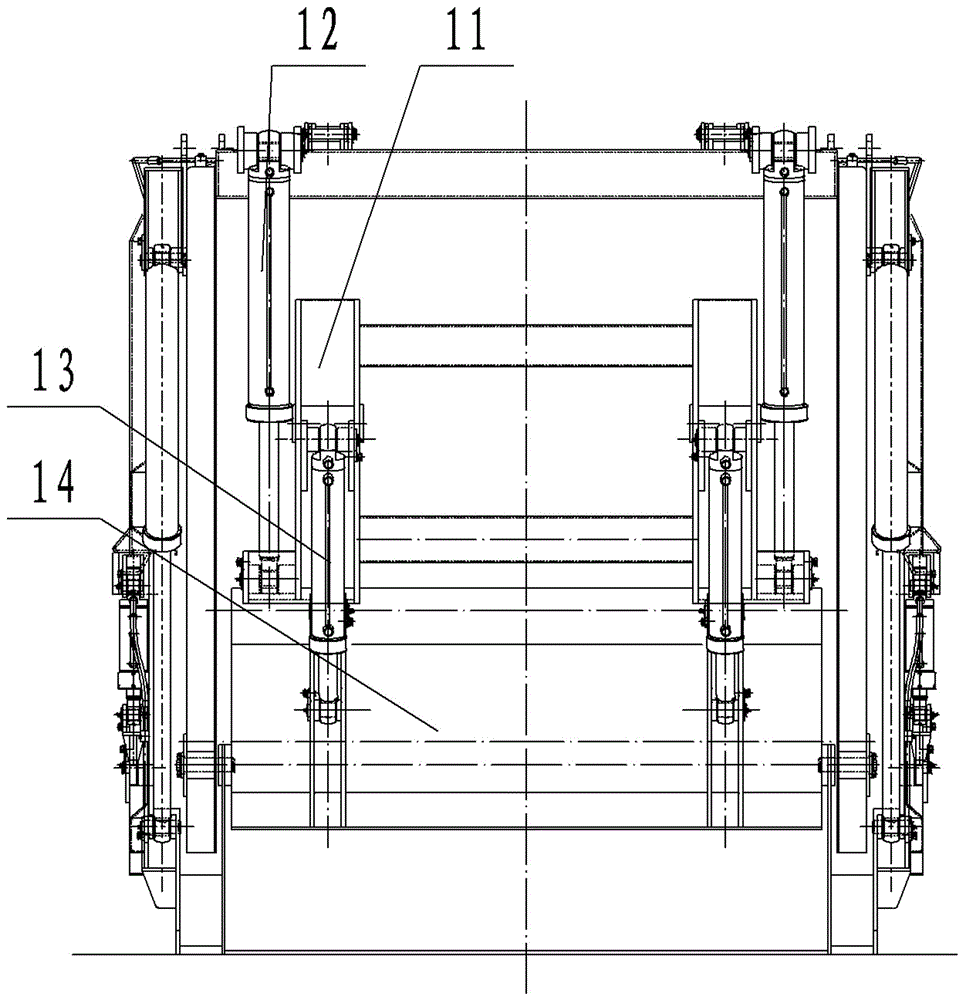

[0031] As shown in the figure: Self-loading compression pull arm carriage, characterized in that it includes a lifting hopper 1 for lifting the carriage and lifting materials, a compressor 2 for compressing materials, and a box for accommodating compressed materials 3 and the hopper fixing pin 4; the lower part of the box body 3 is also equipped with walking wheels, the compressor 2 is fixedly installed on the front part of the box body 3, and there is a push port for the passage of materials between the lower part of the compressor 2 and the box body 3; Lifting hopper 1 has an arc-shaped bottom surface and is hinged under the front of compressor 2. Lifting hopper 1 after rotation and lifting matches the open surface in front of compressor 2 to form a closed space; lifting hopper 1 rotates and lifts and compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com