A method for rapid and directional growth of carbon nanofibers on the surface of carbon fibers

A carbon nanofiber, directional growth technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of low cohesion and low bonding strength, and achieve the effects of low equipment investment, high safety and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

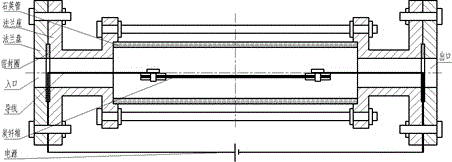

Method used

Image

Examples

Embodiment 1

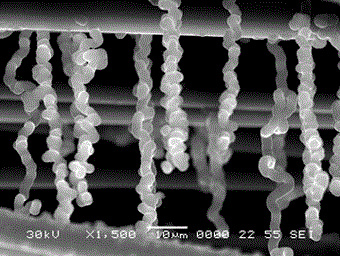

[0025] The untreated carbon fiber (take T700-12K carbon fiber as an example, the fiber length is 10cm, the mass is m=0.0086g), electrified along the length direction, with acetylene as the carbon source gas, nitrogen as the carrier gas, C 2 h 2 =40mL / min, N 2 =60mL / min, the initial deposition voltage is 25V (the selection of the voltage value is different due to the K number and length of the carbon fiber, and the initial power per unit volume is 5*10 9 W·m -3 left or right, select a suitable voltage value), electrify in a steady state, deposit 10-60min, preferably deposit 10-30min, the SEM appearance of pyrolytic carbon deposited on the surface of carbon fiber is as follows figure 2 As shown, the length of oriented pyrolytic carbon can reach 50 μm. As the deposition progresses, the voltage remains constant under constant voltage, and the current decreases continuously, that is, the heating power decreases continuously.

Embodiment 2

[0027] Dry the carbon fiber with the same length and weight as in Example 1 after degumming, take this sample as the cathode, take nickel sulfate as the electroplating solution (200g / L), room temperature, current intensity is 100mA, electroplating 3min, after deionization After soaking in water, cleaning and drying, deposit in the chemical vapor deposition furnace of the present invention, the deposition initial voltage is 25V, and the gas flow rate is C during the deposition process. 2 h 2 =10ml / min, N 2 =200ml / min, the deposition time is 0.5h, and the weight gain of carbon fiber after deposition is 148%.

Embodiment 3

[0029] Dry the carbon fiber with the same length and weight as in Example 1 after degumming, use this sample as the cathode, take nickel sulfate as the electroplating solution (200g / L), room temperature, the current intensity is 100mA, electroplating for 3min, after deionization After soaking in water, cleaning and drying, deposit in the chemical vapor deposition furnace of the present invention, the deposition initial voltage is 25V, and the gas flow rate is C during the deposition process. 2 h2 =30ml / min, N 2 =200ml / min, the deposition time is 0.5h, and the weight gain of carbon fiber after deposition is 276%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com