Vibration reduction steel rail

A technology of rails and damping blocks, which is applied in the field of rails, can solve the problems of increased sleeper noise, increased noise, and no substantial improvement in rail vibration and radiation noise, achieving obvious noise reduction effects and increasing attenuation rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

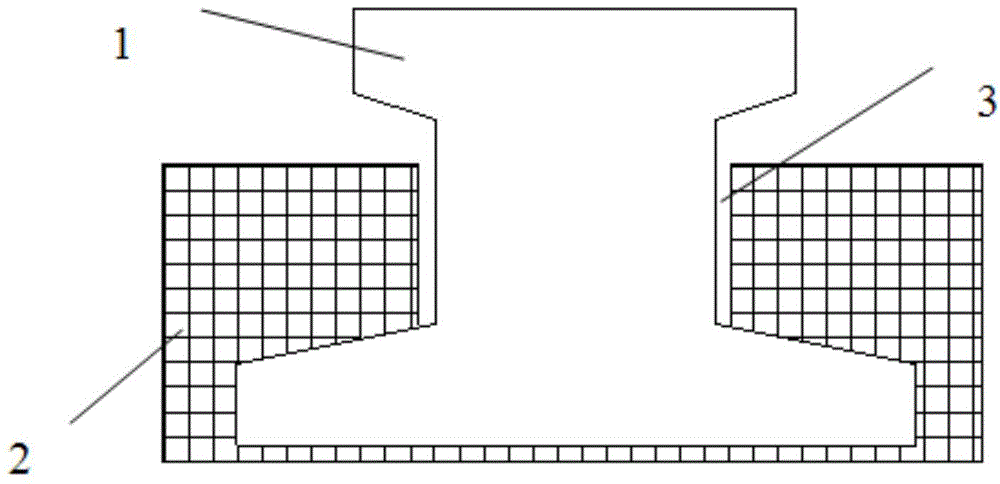

[0011] A shock-absorbing rail is composed of a rail surface, a rail side, a rail waist and a rail bottom, and a shock-absorbing mechanism is arranged at the rail bottom and the rail bottom.

[0012] The damping mechanism is an integral damping block 2 wrapped around the waist of the rail and the bottom of the rail to reduce the mutual friction vibration caused by many parts.

[0013] There is a deformation gap 3 between the shock absorber and the two sides of the rail waist, which can ensure that the rail has a certain expansion space and leave a movement gap.

[0014] The embodiments of the present invention have been described in detail above, but the content described is only a preferred embodiment of the present invention and cannot be considered as limiting the implementation scope of the present invention. All equal changes and improvements made according to the creative scope of the present invention should still belong to the scope covered by this patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com