Analog amplification vacuum tube

A vacuum tube, heat-releasing technology, used in amplifier types, low-frequency amplifiers, audio amplifiers, etc., can solve the problems of reduced manufacturing volume, difficult to obtain, difficult to use fluorescent display tubes, etc., to achieve the effect of improving the attenuation rate and suppressing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]

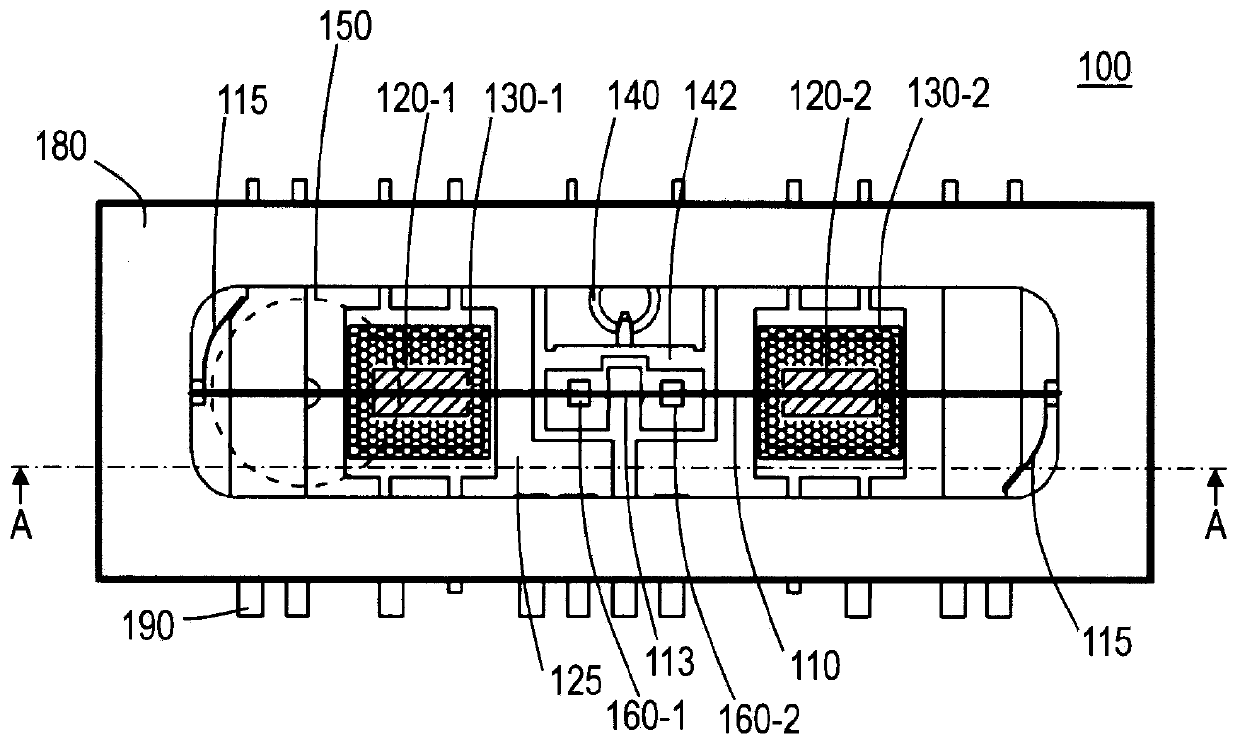

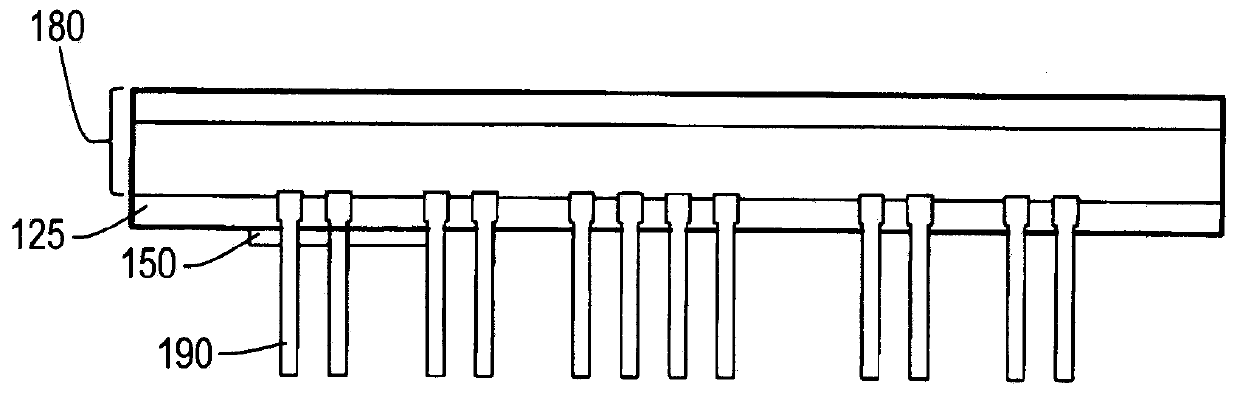

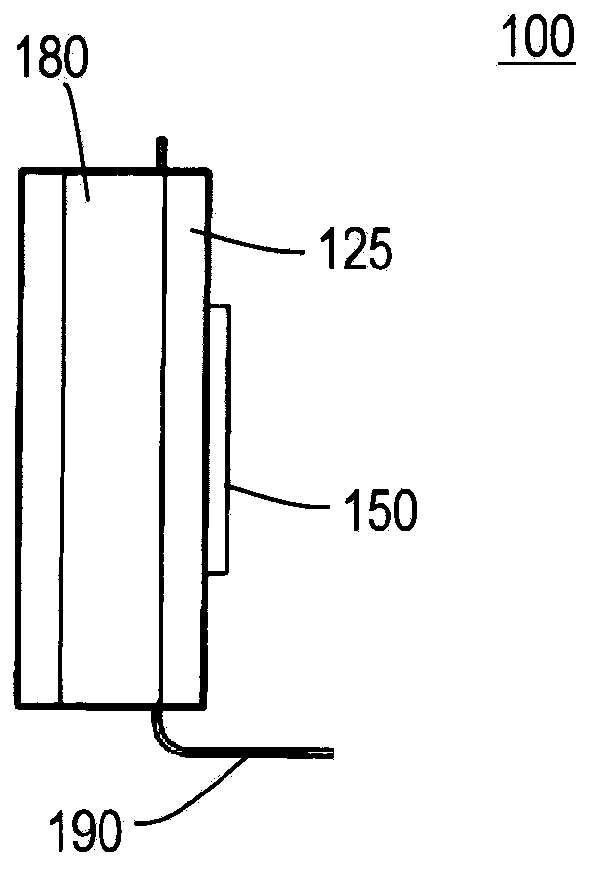

[0033] figure 1 A plan view showing a vacuum tube for analog amplification of the present invention, figure 2 represents the main view, image 3 represents a side view, Figure 4 express figure 1 Sectional view of line A-A. The vacuum tube 100 for analog amplification has: a linearly extending filament 110 that emits thermal electrons at a temperature higher than a predetermined value; 1, 160-2. Both the anodes 120-1 and 120-2 are formed on the same surface of the flat substrate (glass substrate 125). The filament 110 is arranged parallel to the planar substrate (glass substrate 125 ) at a position facing both the anodes 120 - 1 and 120 - 2 . Each of the grids 130-1, 130-2 is disposed on the anodes 120-1, 120-2 so as to face the anodes 120-1, 120-2 of the same group at a first predetermined distance and to have a second predetermined distance from the filament 110. 120-2 and the filament 110. The filament intermediate fixing part 113 which fixes the filamen...

Deformed example 1

[0049] Figure 14 A plan view of a vacuum tube for analog amplification showing a modified example, Figure 15 express Figure 14 Sectional view of the B-B line. The vacuum tube for analog amplification 200 is different from the vacuum tube for analog amplification 100 in that there is only one set of anode 120 , grid 130 , and anti-vibration unit 160 , the position of getter 140 and the method of fixing filament 110 . exist Figure 14 In , in order to easily understand the position of the anode 120, a part of the grid 130 is not described, but the grid 130 and Figure 9 same. In the vacuum tube 200 for analog amplification, since there is only one set of the anode 120 and the grid 130 , it is not necessary to limit the position of the getter 140 in order to adjust the characteristics. Therefore, the getter 140 is provided at the end of the analog amplification vacuum tube 200 in a state held by the getter support member 242 .

[0050] In the vacuum tube 200 for analog a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com