Replaceable enhancement type water joint for immersed tunnel

A technology for immersed tube tunnels and waterproof joints, applied in the field of engineering testing and testing, can solve the problems of reduced safety and reliability of immersed tube tunnels, reduced water sealing effect at joints, and inability to replace them, so as to achieve easy access and operability Good performance, convenient and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

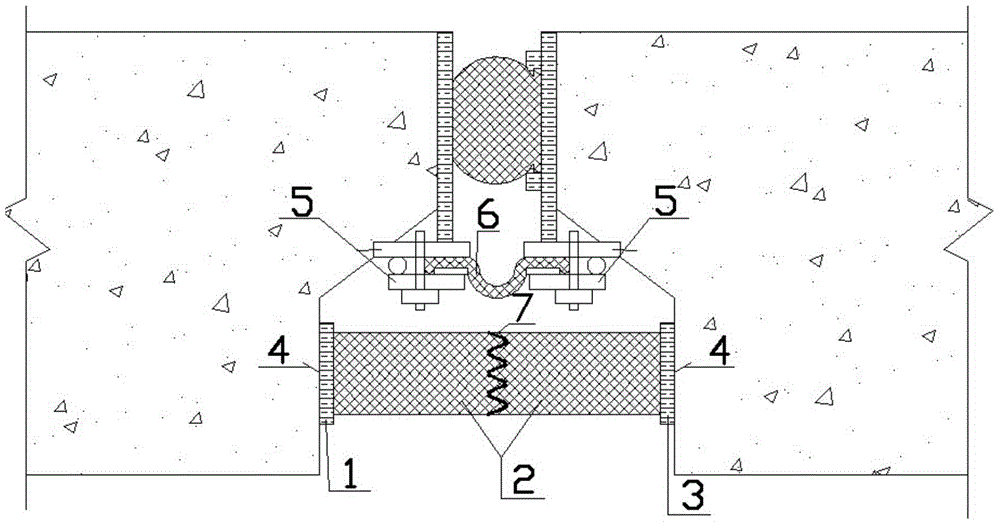

[0008] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0009] As shown in the accompanying drawings, the present invention is a replaceable reinforced immersed tube tunnel waterproof joint. Including A-type end steel shell, B-end steel shell, water-stop steel sheet, high-expansion rubber water-stop belt that expands with water, and zigzag occlusal seam. One section of the water-stop steel sheet is connected to the steel shell, and one end is embedded in the concrete top (bottom) slab. The A-type end steel shell and the B-end steel shell are consolidated with the concrete slab. The high-expansion rubbers at both ends are respectively fixed on the steel shells at both ends. A zig-zag seam is reserved between the high-expansion rubber at both ends.

[0010] If the component is damaged or the component is aging due to time factors, the component can be disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com