Pipe type variable-damping filter provided with multiple holes with different parameters and applied to opening of hydraulic pump

A hydraulic pump and filter technology, which is applied to fluid pressure actuating devices, fluid pressure actuating system components, mechanical equipment, etc. Vibration damping effect, the effect of increasing the vibration damping frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

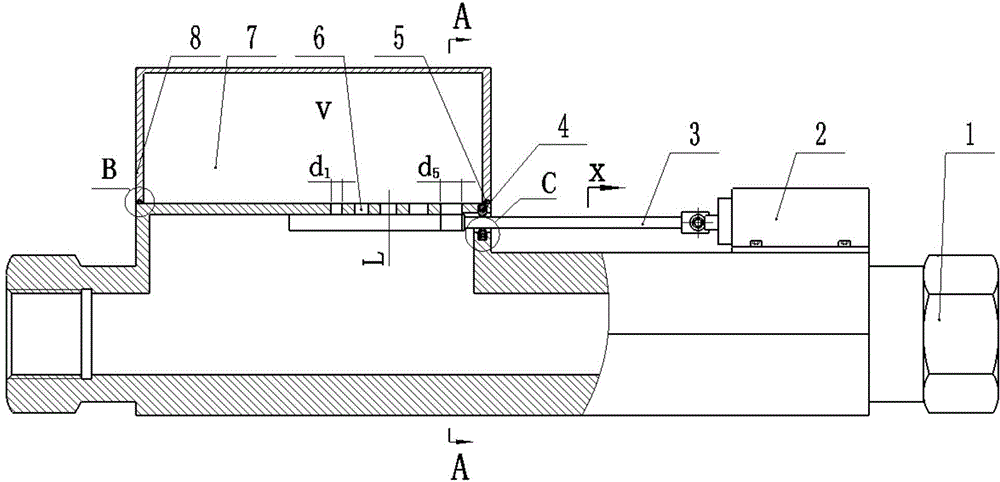

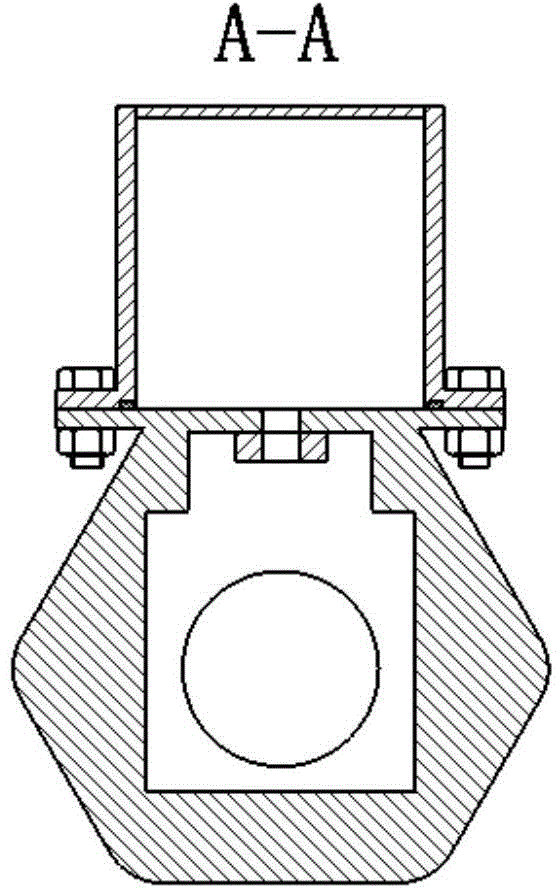

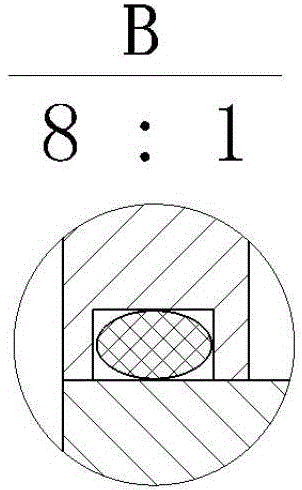

[0026] A kind of porous tubular variable damping filter with different channel parameters of the hydraulic pump port of the present invention, such as figure 1 -Shown in 5, it is made up of main housing 1, small linear motor 2, sliding baffle 3, first sealing ring 4, second sealing ring 5, damping hole 6, oil chamber 7 and oil chamber housing 8. Such as figure 1 As shown, the two ends of the main housing 1 are provided with internal threaded connecting joints, the right end is the oil inlet joint, the left end is the oil outlet joint, and the two joints are used to connect with the hydraulic pipeline; figure 2 As shown, the shell of the main shell 1 is a hexagonal columnar body to improve its power-to-weight ratio; as figure 1 As shown in —2, the upper left end of the main casing 1 is provided with a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com