Anti-siphon structure and anti-siphon method of water inlet valve

A technology of anti-siphon and water inlet valve, which is applied in the direction of valve shell structure, flushing equipment with water tank, valve details, etc., can solve the problem of pulling down the CL line, achieve the position of the CL line, simple structure, and improve the anti-siphon effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

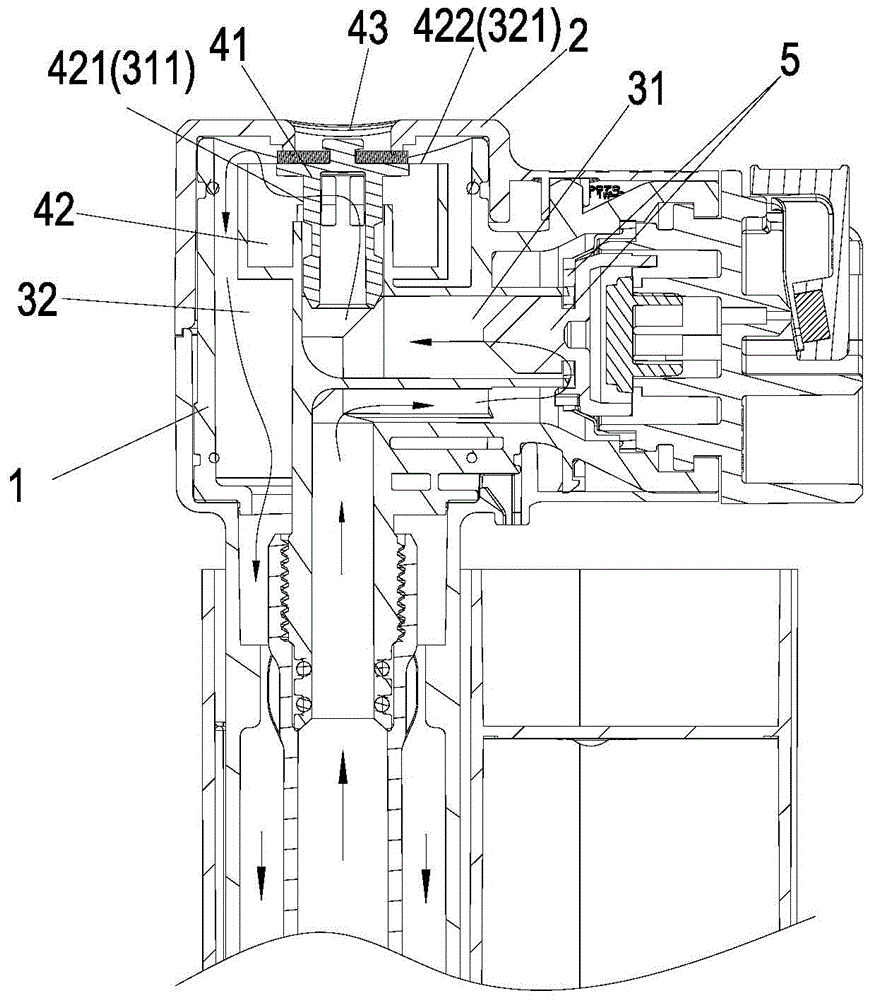

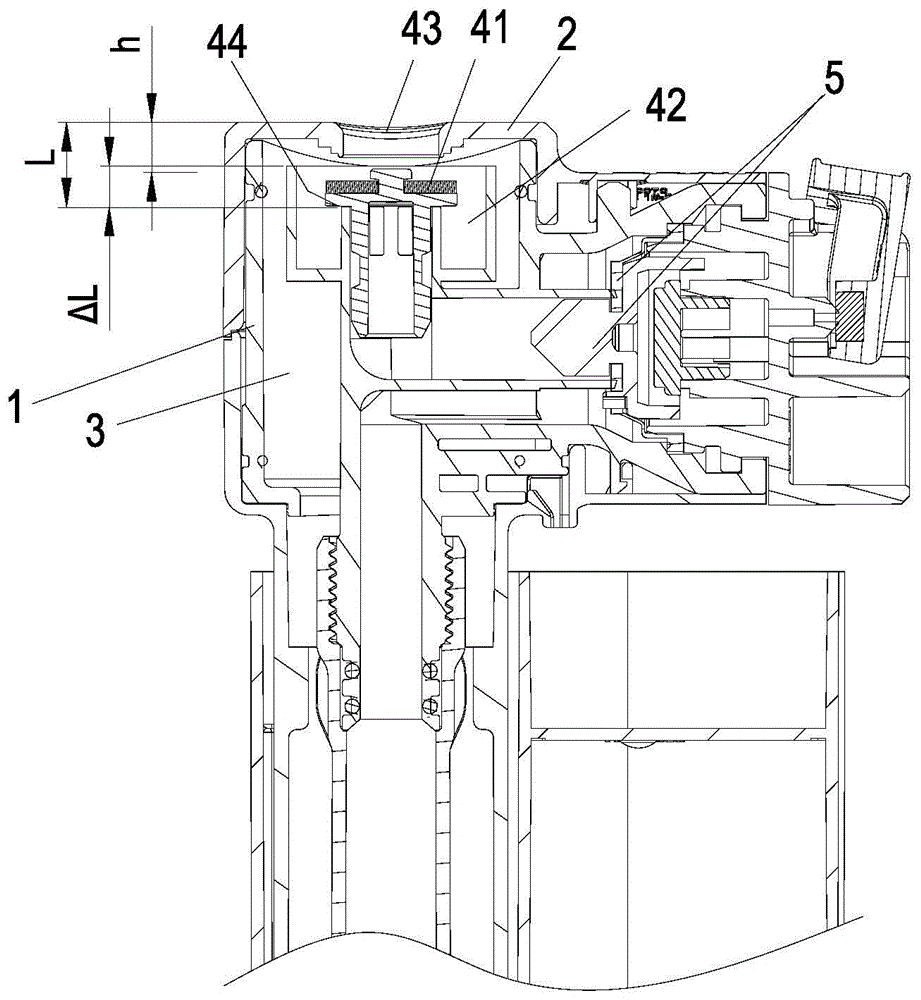

[0034] Please check Figure 1 to Figure 5 , an anti-siphon structure of a water inlet valve, the water inlet valve includes a valve body 1 and a valve cover 2 covered on the valve body 1, the valve body includes a water inlet channel 31 and a water outlet channel 32, the valve body 1 and A valve cavity 3 is formed between the valve covers 2 . In this embodiment, the water inlet valve also includes a water stop component 5 that is movably installed in the valve body 1 and can communicate with or cut off the water inlet channel. In this embodiment, the water stop component 5 is arranged on the side of the top of the valve body 1 .

[0035] The anti-siphon structure includes an air inlet 43 that is located on the top of the valve body 1 and communicates with the inside and outside of the valve body 1. In this implementation, the air inlet 43 is opened on the valve cover 2 at the top of the valve body 1. The air inlet 43 makes the valve cavity 3 connected with the outside air. ...

Embodiment 2

[0044] Please check Figure 7 The difference between this embodiment and Embodiment 1 is that in this embodiment, a notch 3111 is opened at the water outlet end 311 of the water inlet channel 31, and the notch 3111 is used to increase the suction flow area, which can increase the siphon time. Inspiratory volume and increase inspiratory speed.

[0045] Other configurations and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

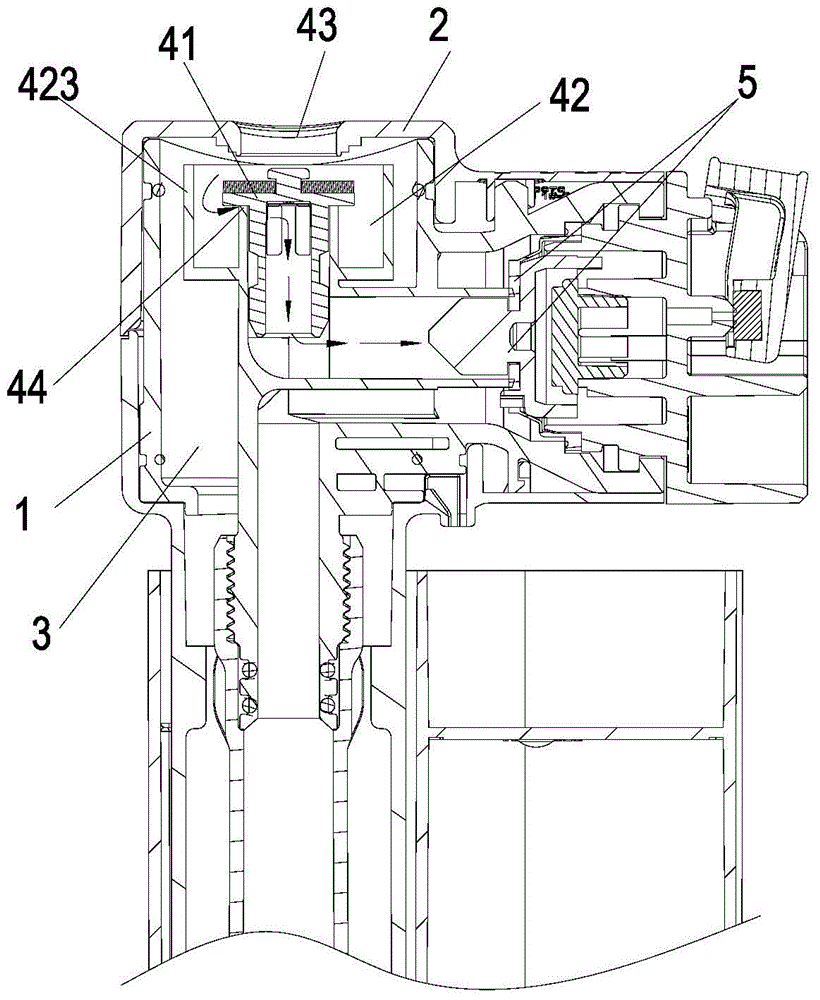

[0047] Please check Figure 8 and Figure 9 , the difference between this embodiment and Embodiment 1 is:

[0048] A transition channel 33 is included between the water inlet channel 31 and the water outlet channel 32, the transition channel 33 is the isolation chamber 42, and the water inlet end 331 of the transition channel 33 is connected to the water outlet end 311 of the water inlet channel, so The water outlet 332 of the transition channel 33 is connected to the water inlet 321 of the water outlet, and the position of the water outlet 332 of the transition channel is higher than that of the water inlet 331 of the transition channel.

[0049] Other configurations and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0050] The anti-siphon method of a water inlet valve according to the present invention is: an air inlet 43 communicating with the inside and outside of the valve body is provided on the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com