A defrosting system for air source heat pump

An air source heat pump, one-way technology, used in lighting and heating equipment, damage protection, refrigeration components, etc., can solve the problems of indoor temperature drop, long defrosting time, lag, etc. frost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

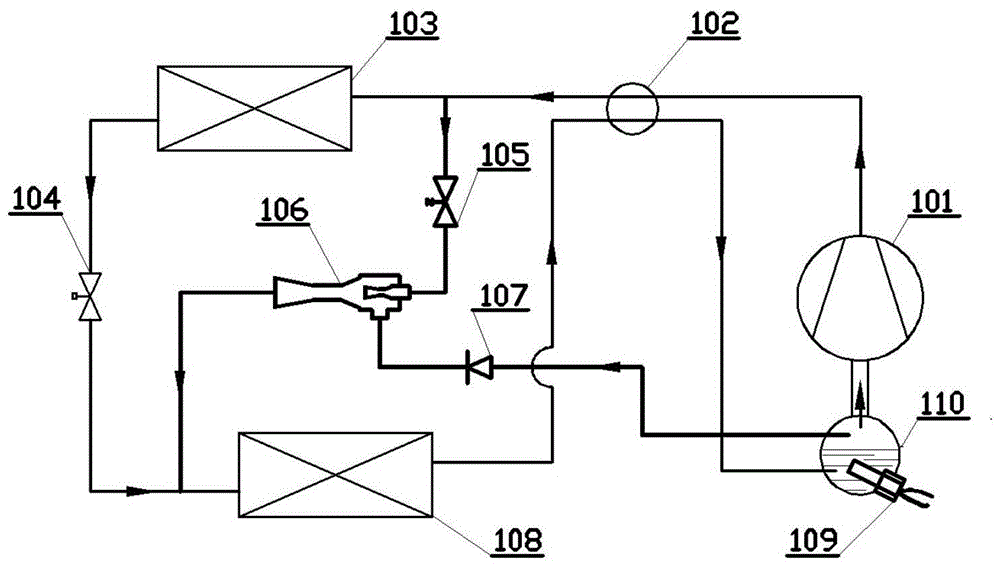

[0027] Such as figure 1 As shown, for the defrosting system of the air source heat pump, the outlet of the compressor 101 is connected with the inlet of the four-way reversing valve 102; The outlet of the indoor heat exchanger 103 is connected to the inlet of the outdoor heat exchanger 108 through the throttling device 104, and the outlet of the outdoor heat exchanger 108 is connected to the compressor 101 through the four-way reversing valve 102. The attached gas-liquid separator is connected; the gas-liquid separator 110 gas outlet of the compressor 101 is divided into two paths, one path is connected with the suction port of the compressor 101, and the other path passes through the one-way throttle valve 107 and the ejector 106 The injected refrigerant inlet is connected; the refrigerant outlet of the ejector 106 is connected with the outdoor heat exchanger 108 inlet; the gas-liquid separator 110 carried by the compressor 101 has an electric heating rod 109 .

[0028] The ...

Embodiment 2

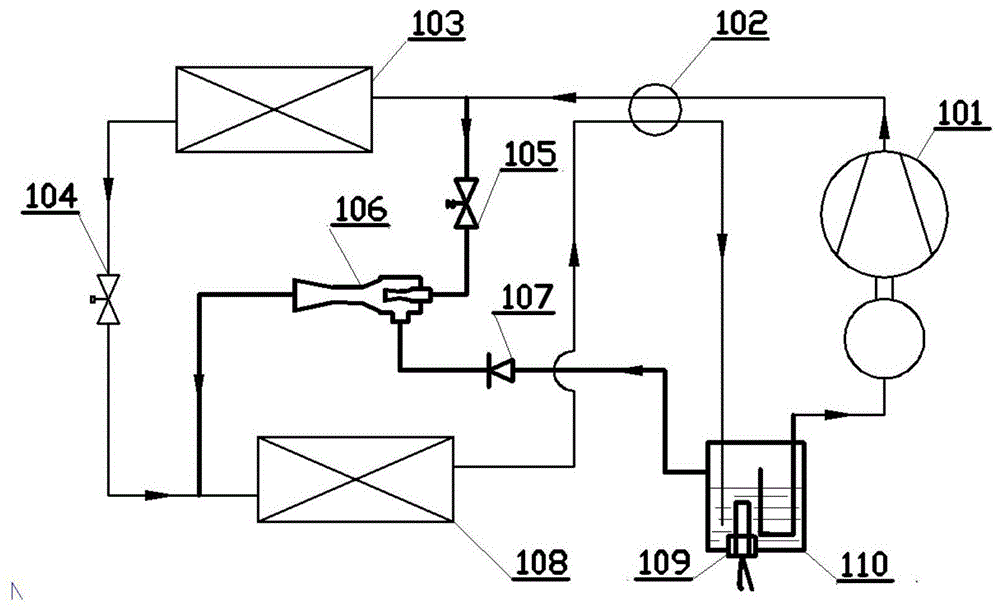

[0031] Such as figure 2As shown, for the defrosting system of the air source heat pump, the outlet of the compressor 101 is connected with the inlet of the four-way reversing valve 102; The outlet of the indoor heat exchanger 103 is connected to the inlet of the outdoor heat exchanger 108 through the throttling device 104, and the outlet of the outdoor heat exchanger 108 is connected to the compressor 101 through the four-way reversing valve 102. The attached gas-liquid separator is connected; the gas outlet of the newly added gas-liquid separator 110 is divided into two paths, one path is connected with the suction port of the compressor 101, and the other path passes through the one-way throttle valve 107 and the ejector 106. The refrigerant inlet of the ejector 106 is connected with the inlet of the outdoor heat exchanger 108; the gas-liquid separator 110 is heated by the electric heating rod 109 inserted therein.

[0032] The high-temperature and high-pressure refrigeran...

Embodiment 3

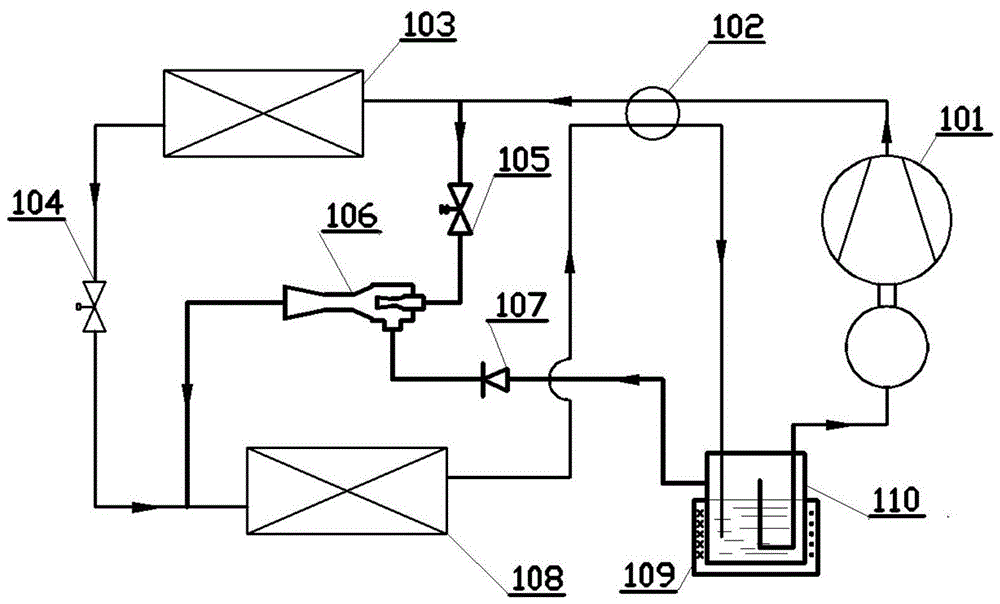

[0035] Such as image 3 As shown, the gas-liquid separator 110 in this embodiment is heated by an electric heating wire wound on the surface of the gas-liquid separator 110 , and the others are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com