Distributed double-sided joint heat storage device for thermal power station

A heat storage device and distributed technology, which is applied in heating methods, heating systems, household heating, etc., can solve the problems of inability to effectively increase the utilization hours of basic heat sources, high operating costs of heating systems, and low heating economy and other issues, to achieve the effect of low construction cost, low working temperature, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

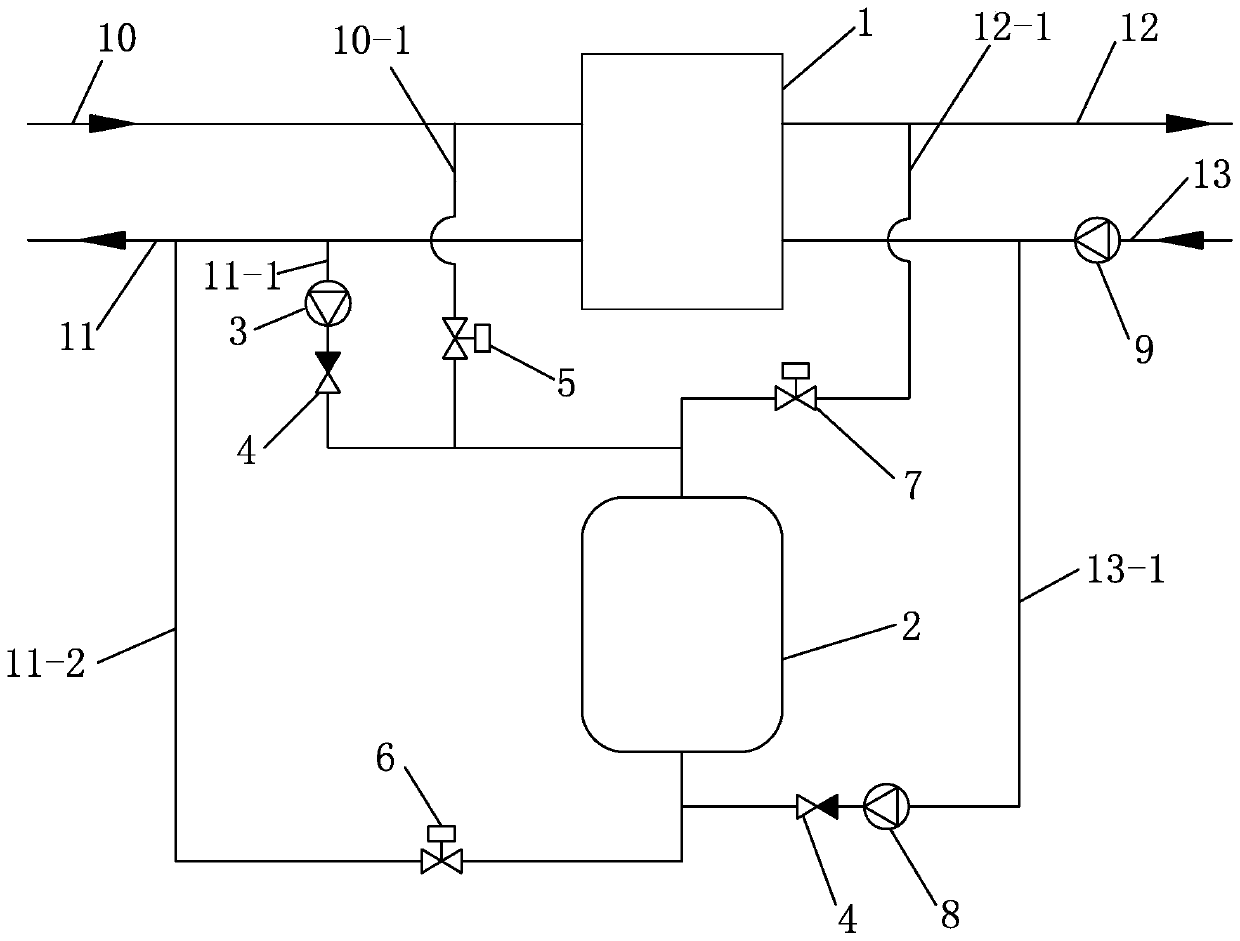

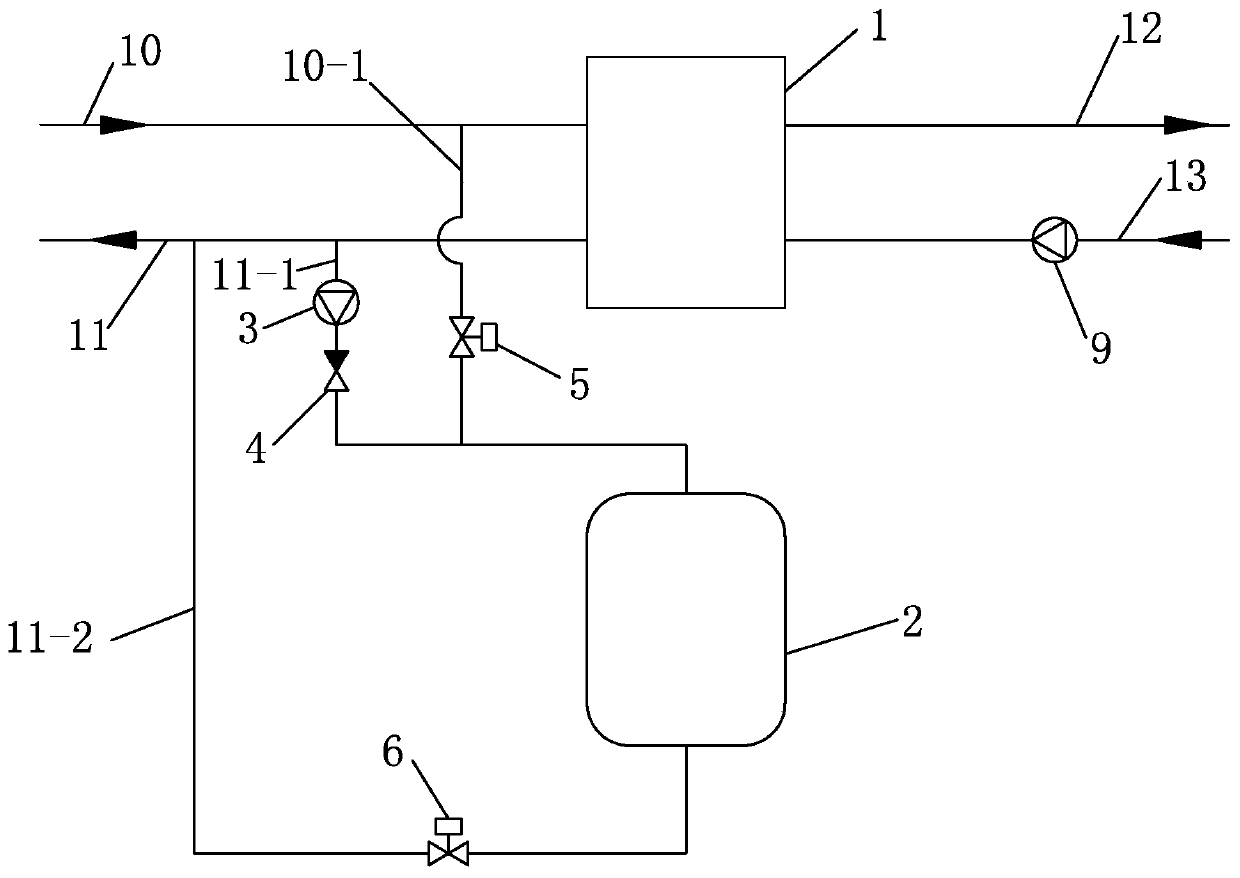

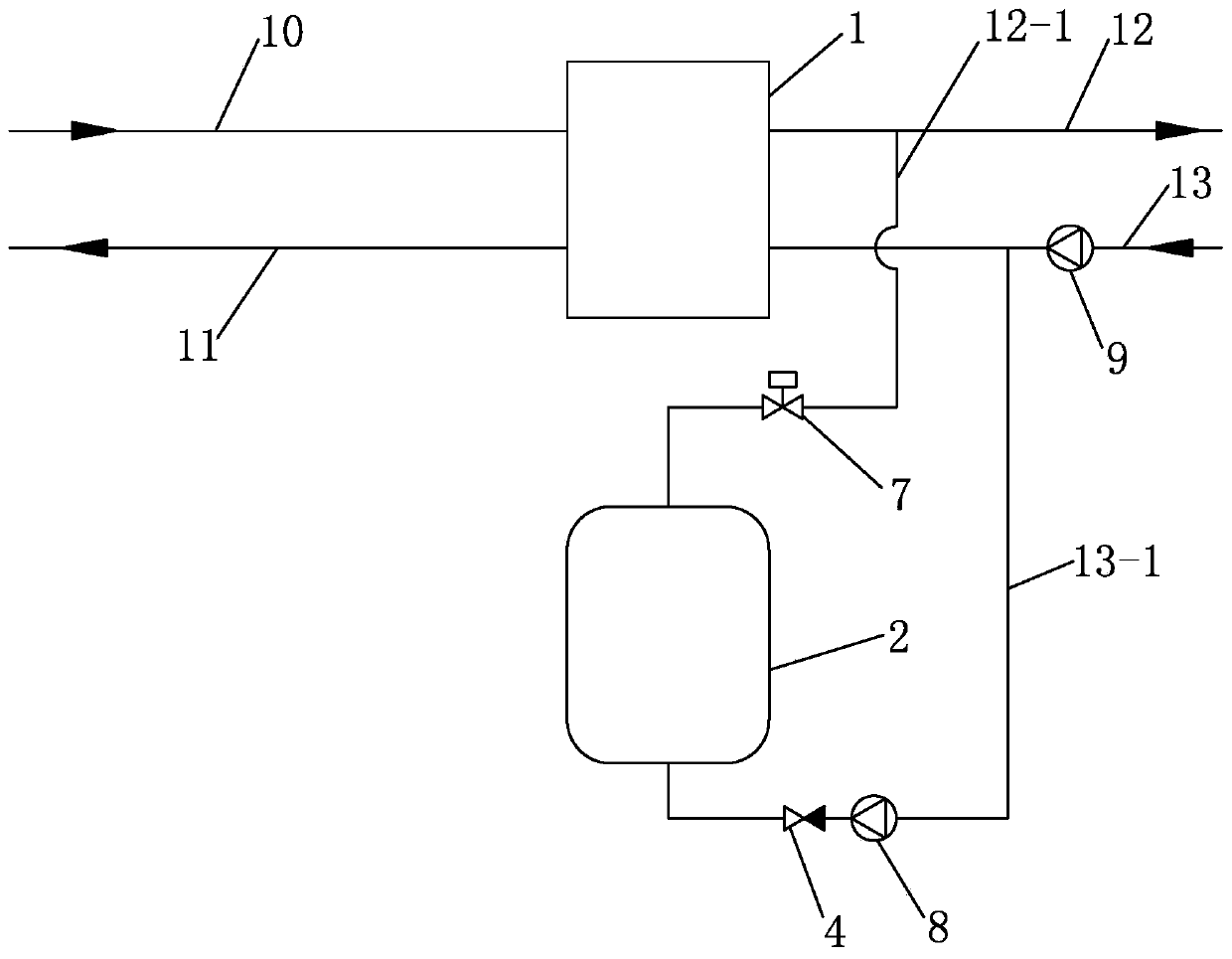

Method used

Image

Examples

Embodiment

[0018] Example: Assume that a thermal station supplies heat to a group of public buildings, with a total heating area of 100,000 m 2 , design area thermal index 75W / m 2 . The building complex has an office heat load during office hours from 6:00 to 22:00, and an on-duty heat load from 22:00 at night to 6:00 the next day. The interior design temperature of the building is different in different time periods, so the heat station There is a significant diurnal cycle variation in the load.

[0019] Assume that the necessary load calculation parameters are as follows in Table 1-Table 3:

[0020] Load calculation parameter table 1

[0021] total heating area heat index per unit area Heating outdoor design temperature S=100,000m 2

q=75W / m 2

t a =-12℃

[0022] Load calculation parameter table 2

[0023] office hours duty time 6:00-22:00 (total 16 hours) 22:00-6:00 the next day (total 8 hours)

[0024] Load calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com