A welding structure of lithium battery pole piece foil and tab

A welding structure and lithium battery technology, applied in structural parts, welding equipment, non-electric welding equipment, etc., can solve the problems of reduced connection strength between battery tabs and nickel strips, unsuitable for battery foils and tabs, etc., to improve The effect of service life, preventing shattering, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

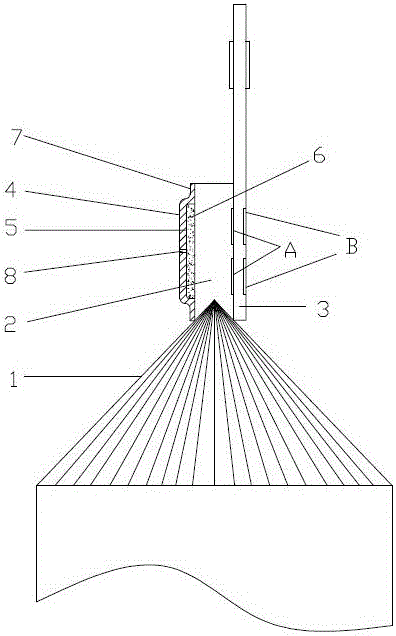

[0023] Embodiment 1: as figure 1 The welding structure of a lithium battery pole piece foil and tab is shown, including an electrode 2 formed by stacking a number of pole piece foils 1 together. The electrodes include a positive electrode and a negative electrode, and the pole piece foils 1 are welded together. connection, the right side of the electrode 2 is welded with a tab 3, the upper end of the tab is provided with a tab glue, the other side of the electrode 2 is provided with a shock absorber 4, and the inner side of the shock absorber 4 is provided with a shock absorber cavity 5, which absorbs The shock cavity is filled with high temperature resistant glue 6, and the periphery of the shock absorber 4 extends outward to form an annular welding surface 7. The annular welding surface has a back-shaped structure, and the welding connection between the annular welding surface 7 and the electrode 2 is welded. The bottom is provided with a through hole 8 . First, the shock a...

Embodiment 2

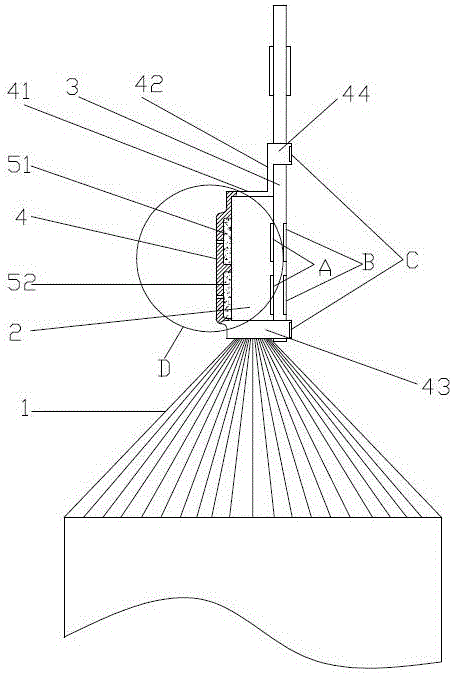

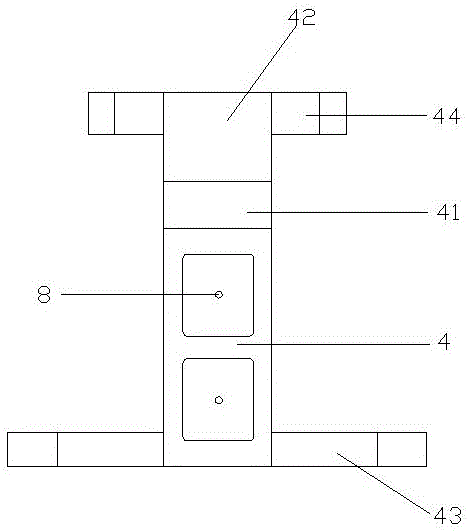

[0024] Embodiment 2: as figure 2 The welding structure of a lithium battery pole piece foil and tab is shown, including an electrode 2 formed by stacking a number of pole piece foils 1 together. The electrodes include a positive electrode and a negative electrode, and the pole piece foils 1 are welded together. connection, the right side of the electrode 2 is welded with a tab 3, the upper end of the tab is provided with a tab glue, the other side of the electrode 2 is provided with a shock absorber 4, and the inner side of the shock absorber 4 is provided with a shock absorber cavity 5, which absorbs The shock cavity is filled with high temperature resistant glue 6, and the periphery of the shock absorber 4 extends outwards to form an annular welding surface 7, which is in a back-shaped structure, and the welding connection between the annular welding surface 7 and the electrode 2, such as Figure 4 As shown, the shock absorbing chamber 5 is provided with spacers 9, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com