Circuit board manufacturing method

A manufacturing method and circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as cracking electronic components, circuit board failure, and difficult punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The manufacturing method of the circuit board provided by the technical solution will be further described in detail below with reference to the drawings and multiple embodiments.

[0030] The method for manufacturing a circuit board provided in the first embodiment of the technical solution includes steps:

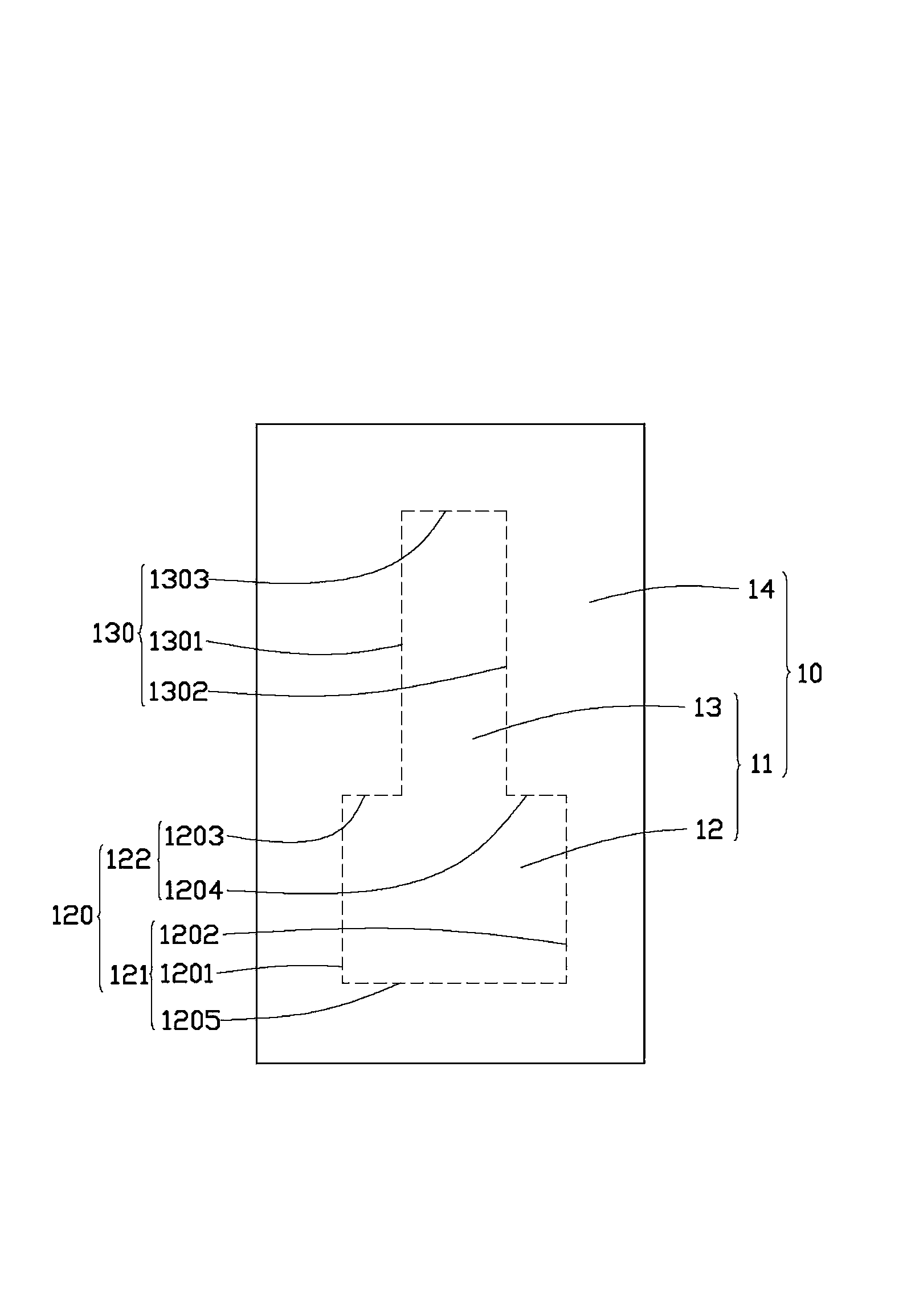

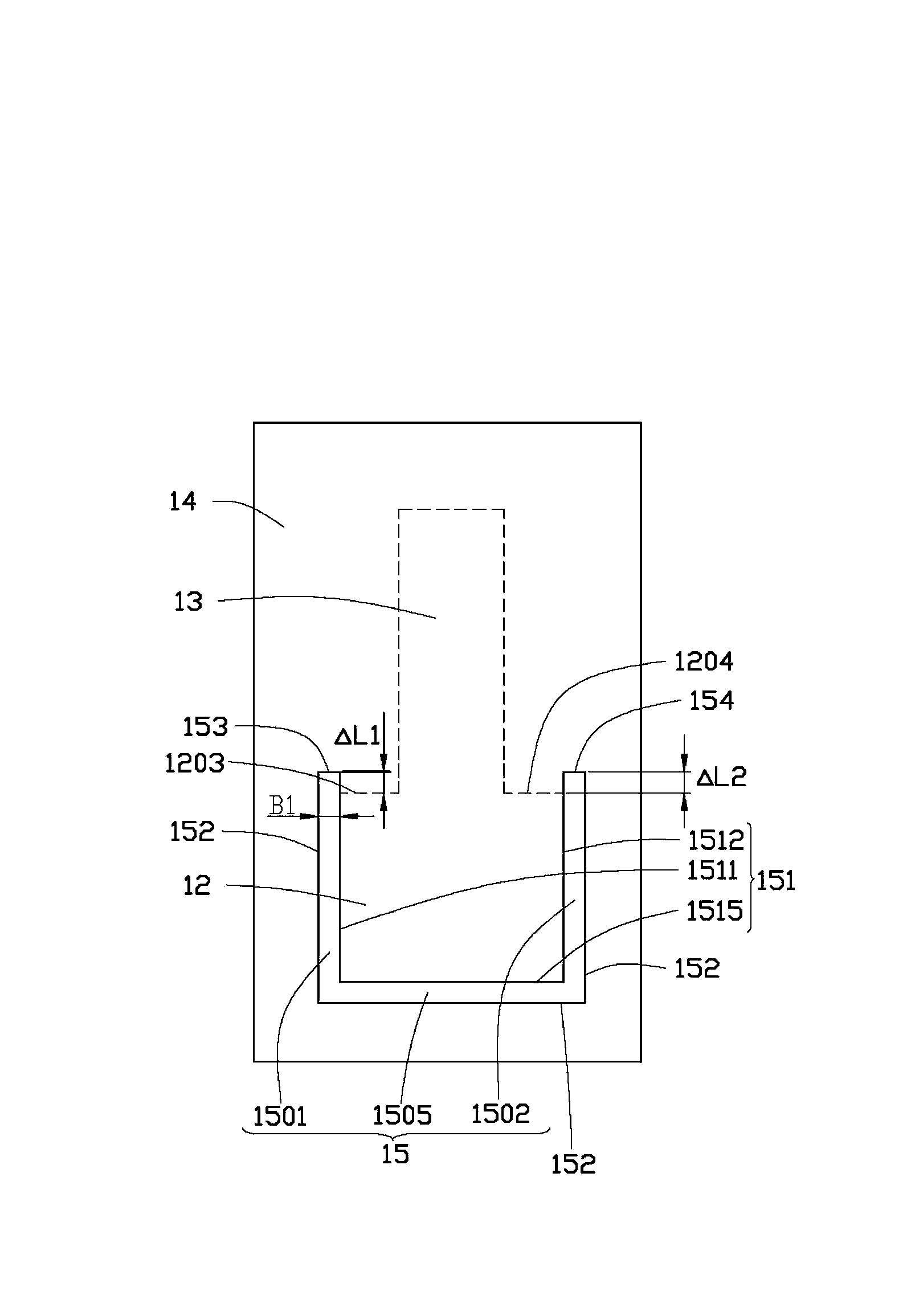

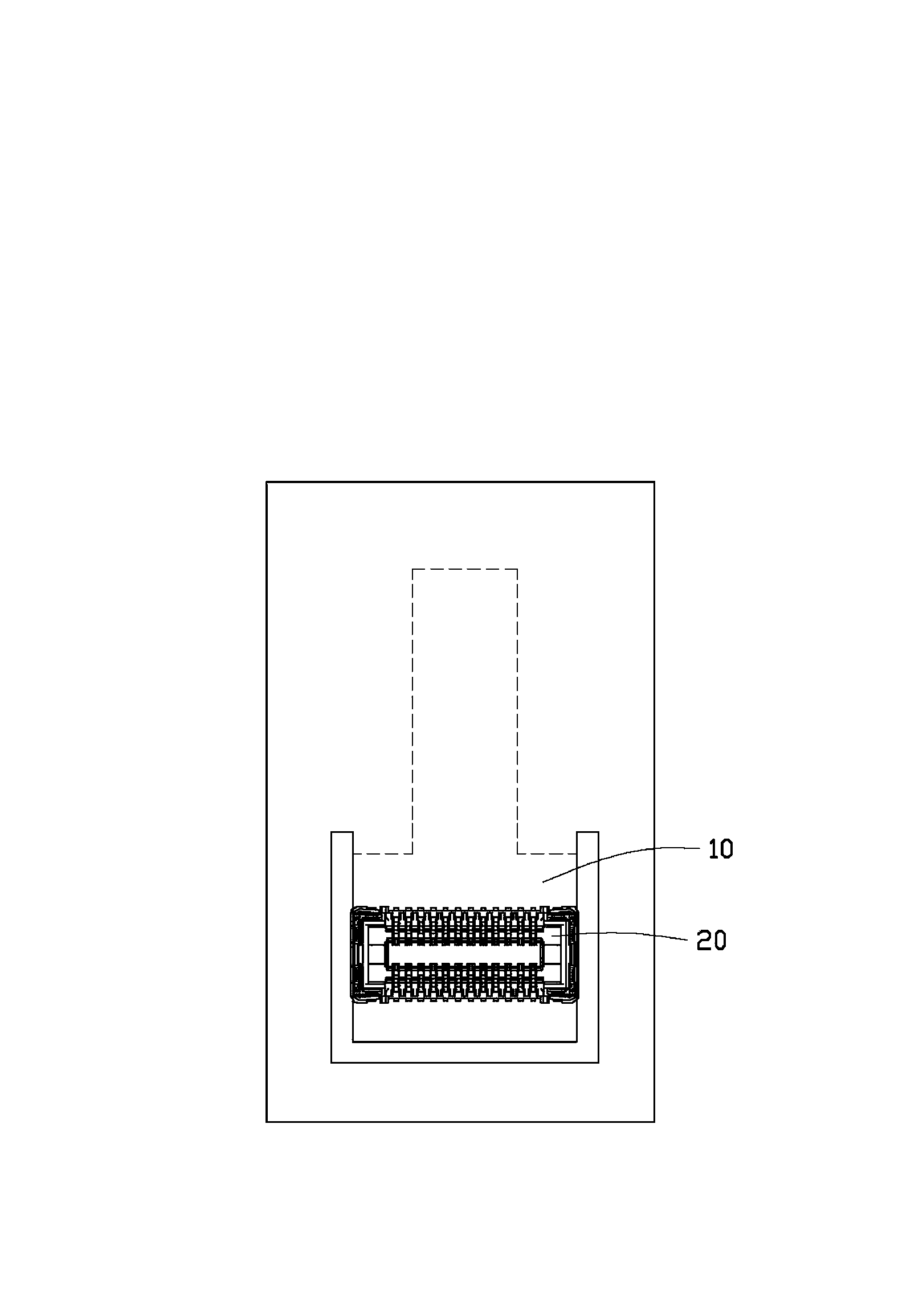

[0031] For a first step, see figure 1 , providing a circuit substrate 10 , the circuit substrate 10 includes a circuit board unit 11 and a waste portion 14 surrounding and connecting the circuit board unit 11 . The circuit board unit 11 is a finished circuit board unit to be assembled with electronic components and to be separated from the waste part 14 by punching after completing the steps of drilling, electroplating, circuit making, solder mask printing and the like. Those skilled in the art can understand that the surface of the circuit board unit 11 has a solder resist layer and connection pads exposed from the solder resist layer, etc. figure 1 The circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com