Thermoelectric Generator

A technology of thermoelectric generator and thermoelectric power generation, which is applied in the direction of generator/motor, electrical components, etc., and can solve the problems of limited power, loose structure, and inability to fully utilize heat sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

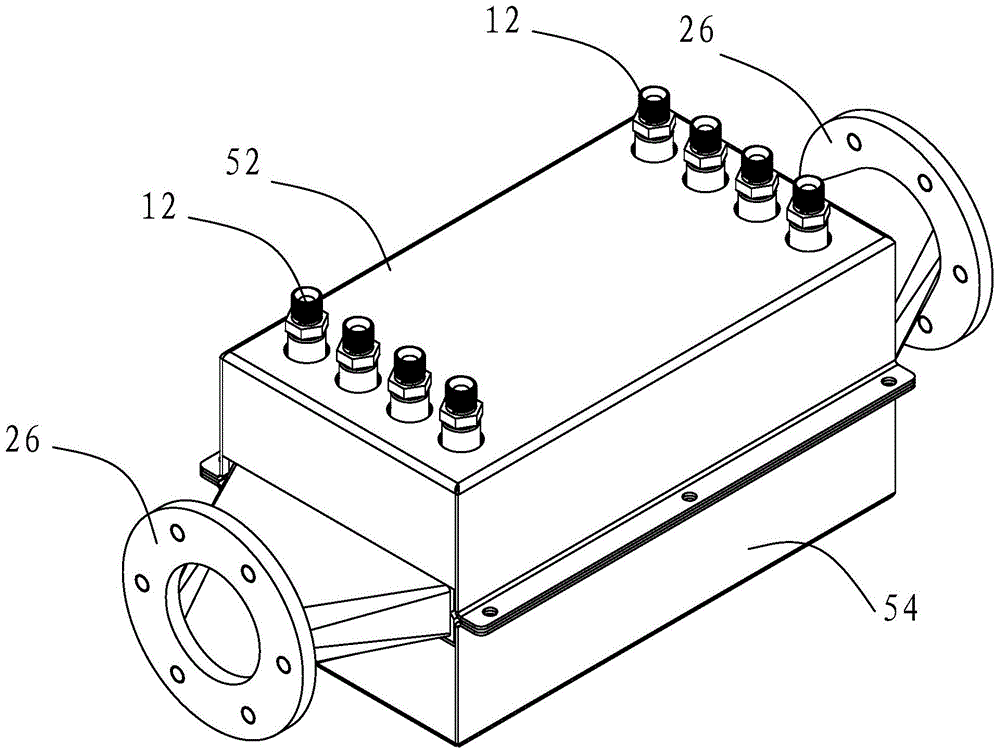

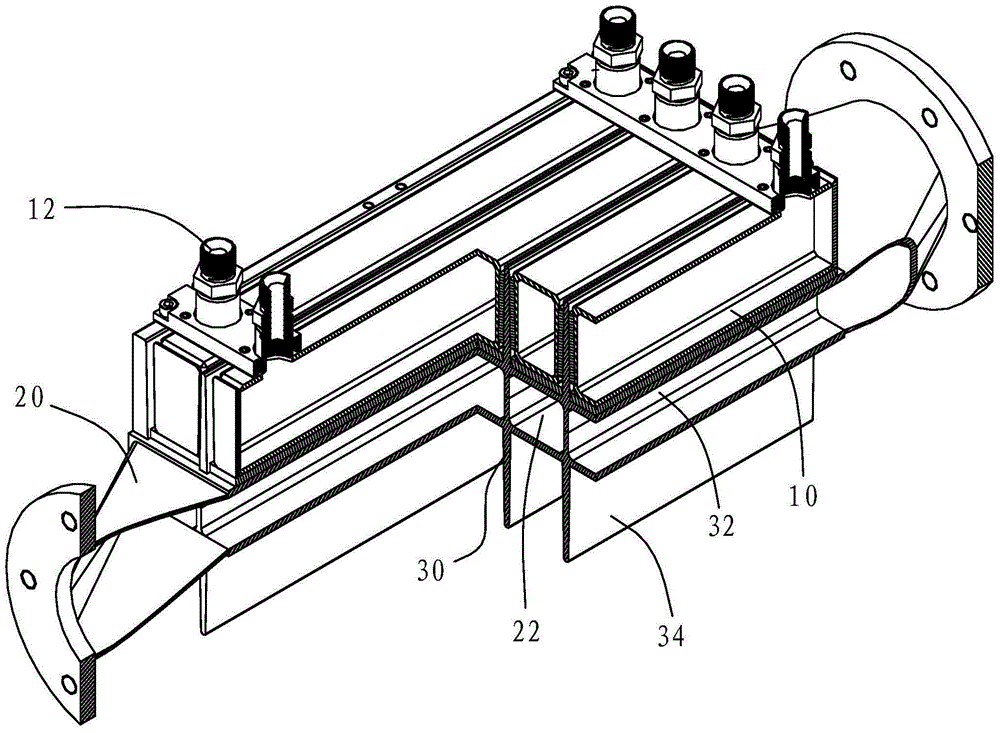

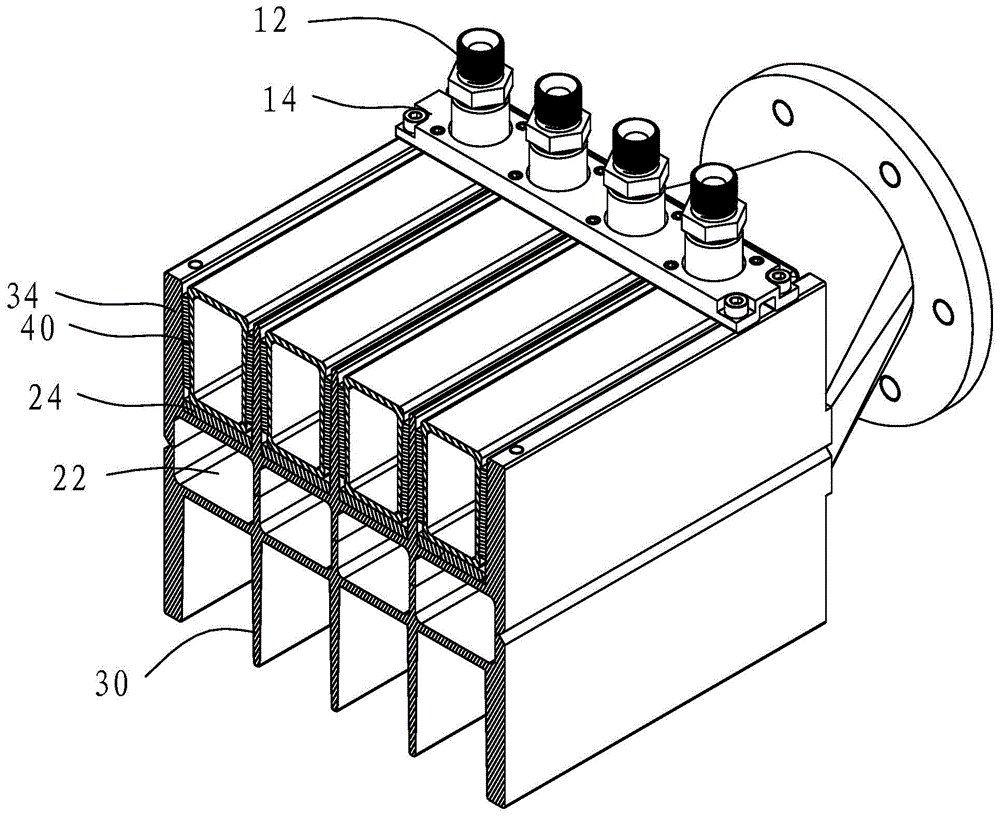

[0028] Such as Figure 1 to Figure 3 As shown, a thermoelectric generator includes a plurality of cooling channels 10, a heat flow channel 20, a plurality of heat conduction plates 30 and a plurality of thermoelectric power generation elements 40, and the heat conduction plates 30 pass through the heat flow channels 20 to longitudinally separate them ( Such as Figure 5 As shown), the heat conduction plate 30 located in the heat flow channel 20 is an inner fin 32, and the heat conduction plate 30 located outside the heat flow channel 20 is an outer fin 34, and the inner fin 32 cooperates with the heat flow channel 20 A plurality of inner passages 22 are formed, the cooling passage 10 is provided between every two outer fins 34, and the thermoelectric device 40 is arranged between the outer fins 34 and the cooling passage 10. After the two thermoelectric generating elements 40 are electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com