Anti-overturning chuck and absorbing type self-moving device using anti-overturning chuck

An adsorption-type, self-moving technology, applied in the field of robots, can solve problems such as stuck, the robot cannot work normally, and the suction cup is overturned, so as to achieve the effect of ensuring normal work, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

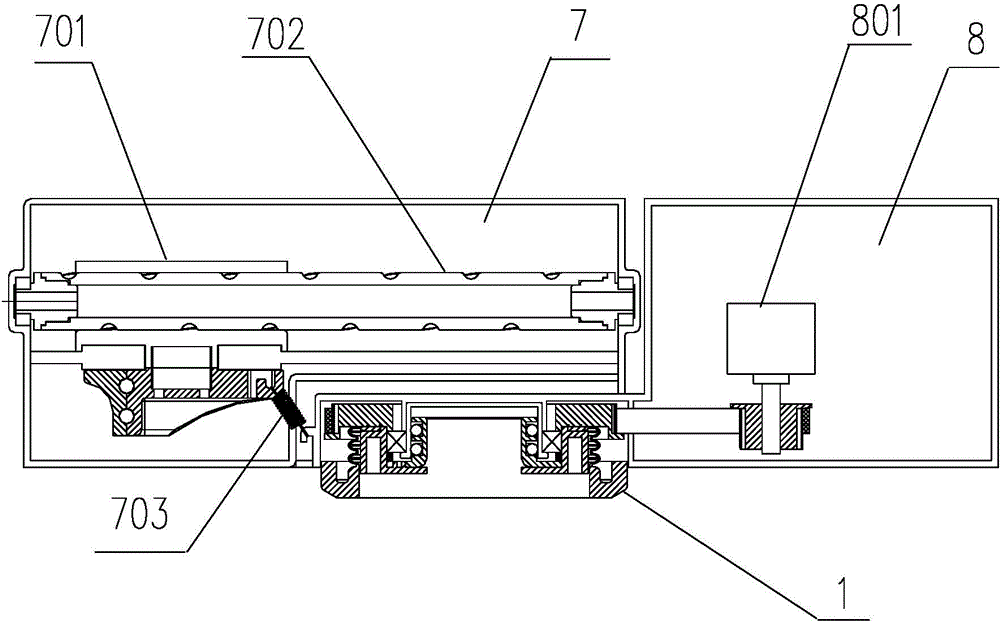

[0023] Introduce an embodiment of the anti-overturn suction cup of the present invention below in conjunction with accompanying drawing.

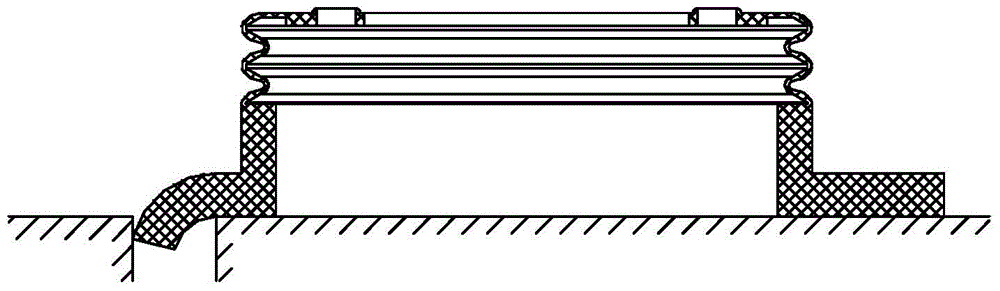

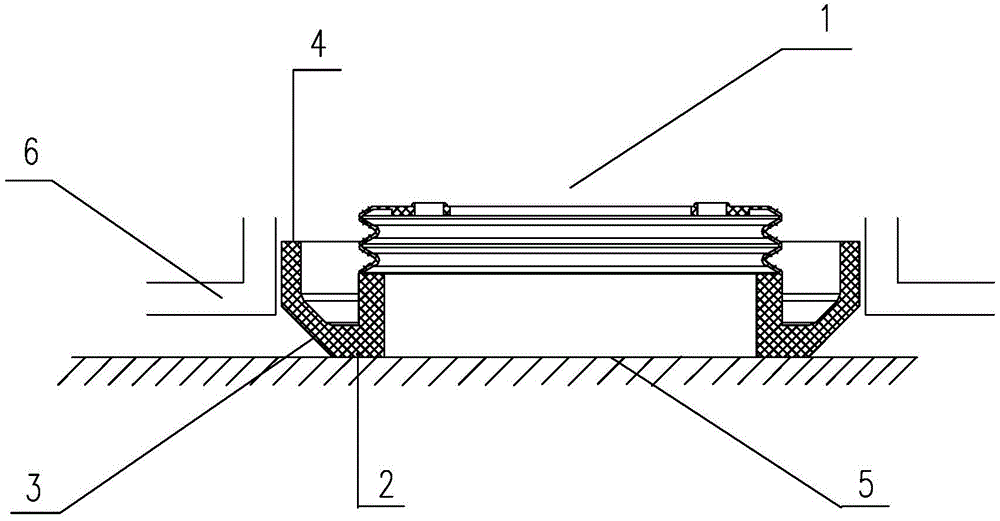

[0024] like figure 2 As shown, an anti-turning suction cup 1 includes a suction cup bottom 2 that is sealed with a working surface 5 , and a raised portion 3 that deviates from the working surface 5 is provided on the outer side of the suction cup bottom 2 . More preferably, the top of the raised portion 3 is further provided with a blocking portion 4, and the blocking portion 4 extends upwards for a certain distance from the top of the raised portion.

[0025] In this embodiment, the surface of the raised portion 3 is set as an inclined surface, and the angle between the inclined surface and the working surface is 20°-50°, preferably 30°. When the angle between the inclined surface and the working surface is small (such as less than 20°), the top of the raised part of the suction cup is easy to be lower than the highest point of the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com