Water shield for grinding machine

A waterproof cover and grinding machine technology, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve problems such as short circuit of wires, large amount of water stains, impact on environmental sanitation, etc., to avoid short circuit of wires and the effect of electric shock hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

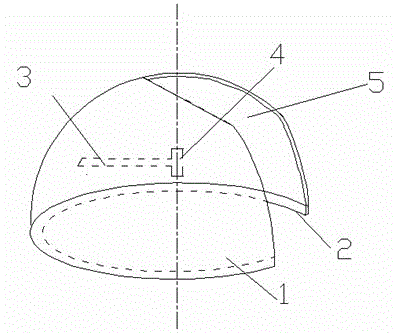

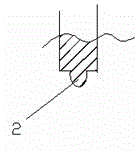

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The present invention includes a waterproof cover 1, a flange 2 fixed on the lower edge of the waterproof cover 1 and a bracket 3 fixed on the inner side of the waterproof cover 1; One end of 3 is fixedly connected to the inner side of the waterproof cover 1, and the other end can be engaged with the central axis of the grinder.

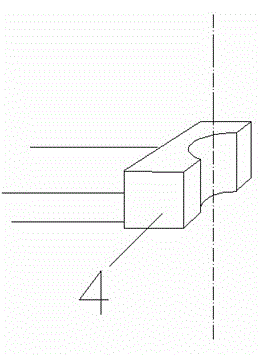

[0012] The part of the bracket 3 engaging with the central axis of the grinder is a protrusion 4 with a semicircular groove on the side, and the semi-cylindrical groove on the side of the protrusion 4 has a radius of at least 20 mm. Because the bracket can be engaged with the central shaft of the grinder, the waterproof cover can not only be fixed to the grinder through the flange, but also can be clamped and fixed with the central shaft on the grinder through the bracket, thereby enhancing the firmness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com