Plate tray stacking conveyor structure

A technology of accumulative conveying and pallets, which is applied in the structural field of plate-shaped pallet accumulative conveyors, can solve the problems of high cost of use, complex structure, occupation, etc., and achieve the effect of low cost of use and simple conveying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

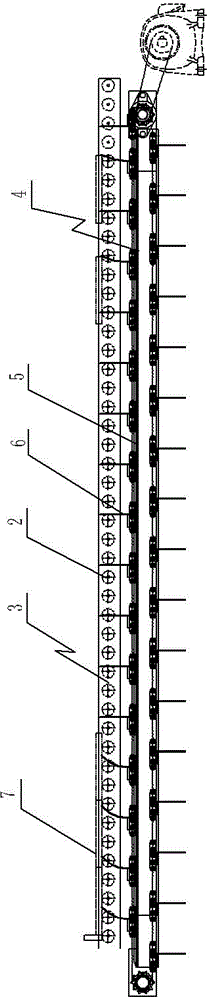

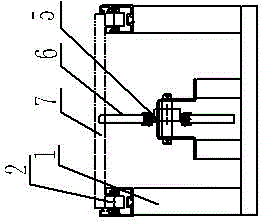

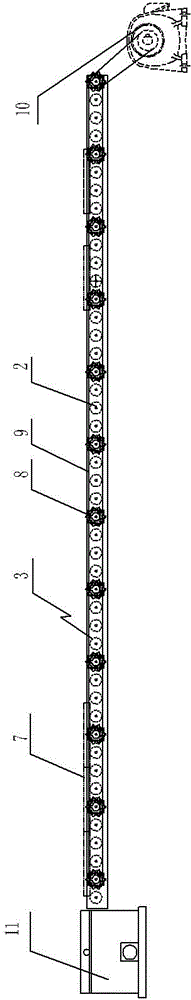

[0017] See image 3 , Figure 4 , Figure 5 As shown, a plate-shaped tray accumulation conveyor structure, which includes a roller bracket 1, the two sides of the roller bracket 1 are respectively provided with a roller conveyor line 3 composed of a plurality of rollers 2, and the roller conveyor line 3 on one side is separated by a certain number. The roller 2 is provided with a sprocket 8 coaxial with the roller 2, and the multiple sprockets 8 are connected by a conveyor belt 9, the sprocket 8 on one side of the roller conveyor line 3 is connected to the drive motor 10, and the end of the roller conveyor line 3 is connected to the tray receiving Device 11, the tray receiving device 11 includes a frame 12, a support wheel conveyor is arranged on the frame 12, the support wheel conveyor includes two support wheel conveying lines 13 arranged side by side, and two support wheel conveying lines 13 are arranged between The jacking cylinder 14, the racks 12 on both sides of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com