Novel assembled shear wall structure

A shear wall, prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of unclear and reduced vertical continuous force transmission, achieve clear force transmission paths, simple construction operations, and solve the problem of vertical continuous force transmission. Unclear effect to continuous force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

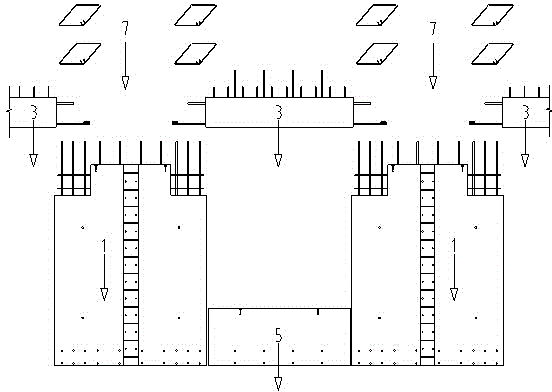

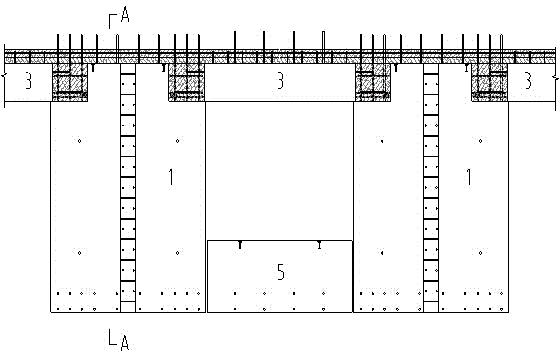

[0023] The split system of the assembled shear wall structure proposed by the present invention is as follows:

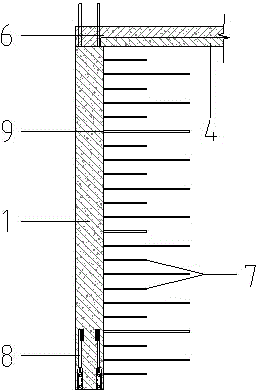

[0024] 1. Prefabricated exterior wall panels 1 are prefabricated with flanges at the joints of corner walls, as shown in the attached Figure 5 shown. The edge component stirrups 7 and horizontally distributed steel bars 9 are reserved through the prefabricated exterior wall panel 1, and are connected with the horizontally distributed steel bars 9 left by the prefabricated external wall panel in the other direction in the cast-in-place area. The length of the cast-in-place part 6 is distributed horizontally. The minimum lap length of the reinforcement is determined. The on-site installation sequence is as follows: after the prefabricated exterior wall panel 1 is installed and positioned, the horizontally distributed steel bars 9 of the prefabricated external wall panel 1 in the other direction should be split outward in advance, and the horizontally distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com