Multi-stage fracturing intelligent control system

An intelligent control system and intelligent technology, applied in the fields of fluid production, measurement, wellbore/well components, etc., can solve the problems of inability to switch operations in a single layer, low reliability, and well scrapped, to avoid unidentifiable operations, The effect of avoiding misoperation and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

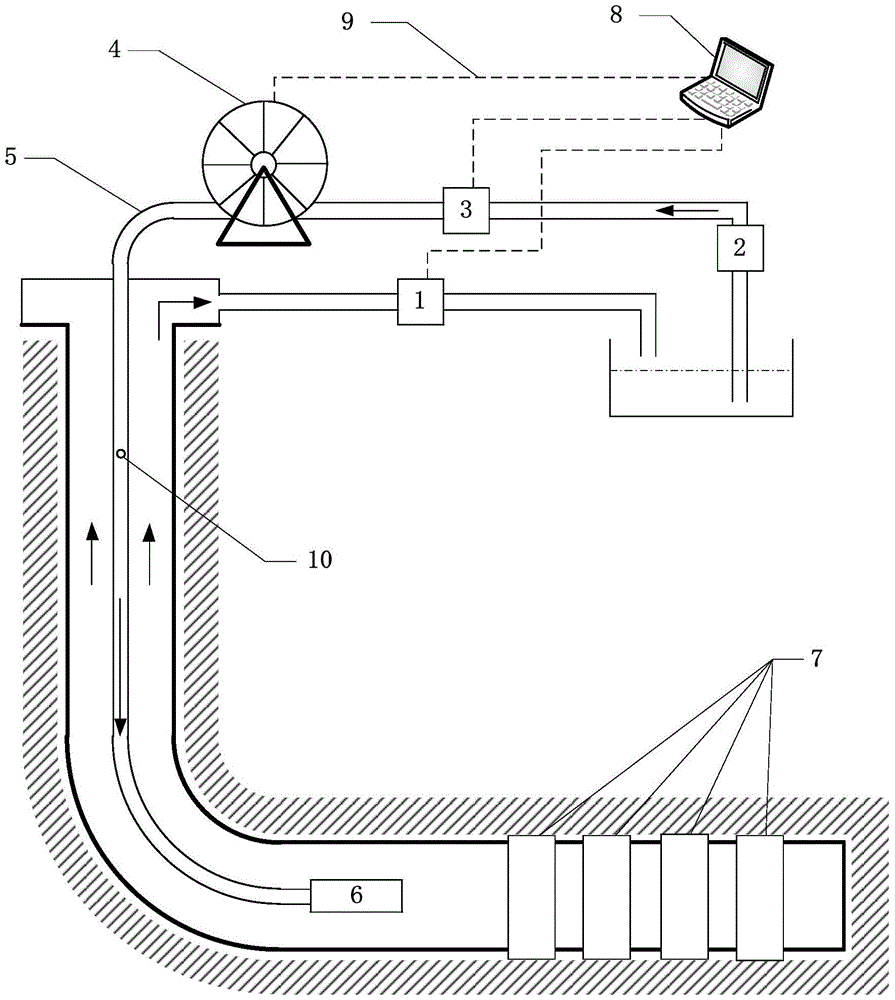

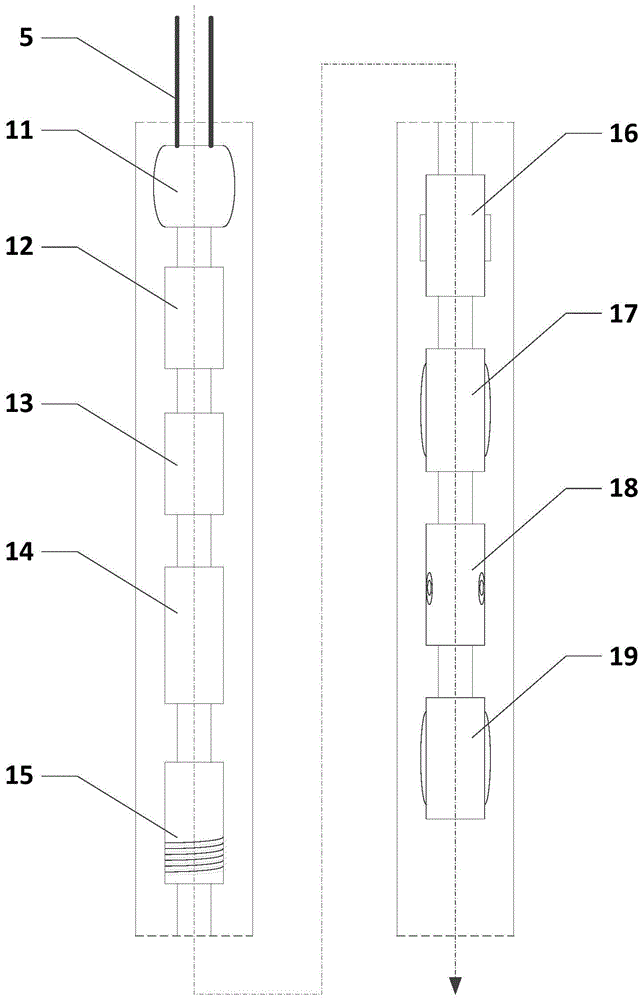

[0028] Such as Figure 1 to Figure 3 As shown, the multi-stage fracturing intelligent control system according to the embodiment of the present invention includes intelligent fracturing and positioning pipe string 6, mud pulse signal receiver 1, RFID tag delivery device 3, multi-section intelligent casing sliding sleeve 7, Coiled tubing vehicle 4, in which:

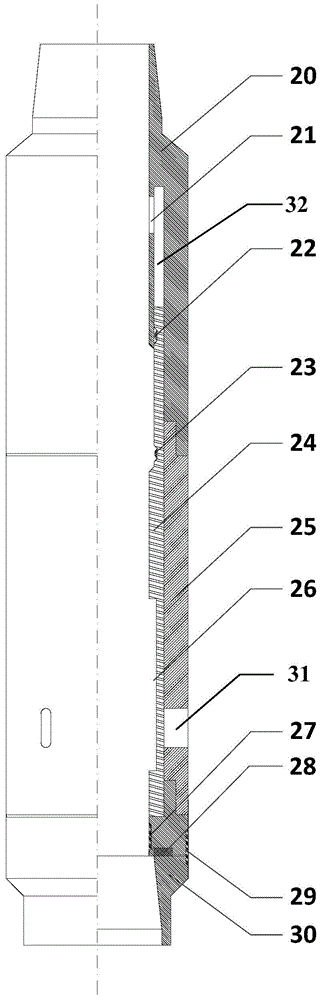

[0029] Described smart casing sliding sleeve 7 comprises main body, the smart sliding sleeve RFID tag 28 that is installed on the main body, the inner coil 27 that is connected to described smart sliding sleeve RFID tag 28 and information writing outer coil 29, and the information Writing outer coil 29 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com