Heavy oil burner

A technology of heavy oil burning and stabilizing burner, applied in burners, burners, liquid fuel burners, etc., can solve the problems of high production cost, only burning light oil, poor atomization effect, etc., and achieve good atomization quality , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the drawings and embodiments:

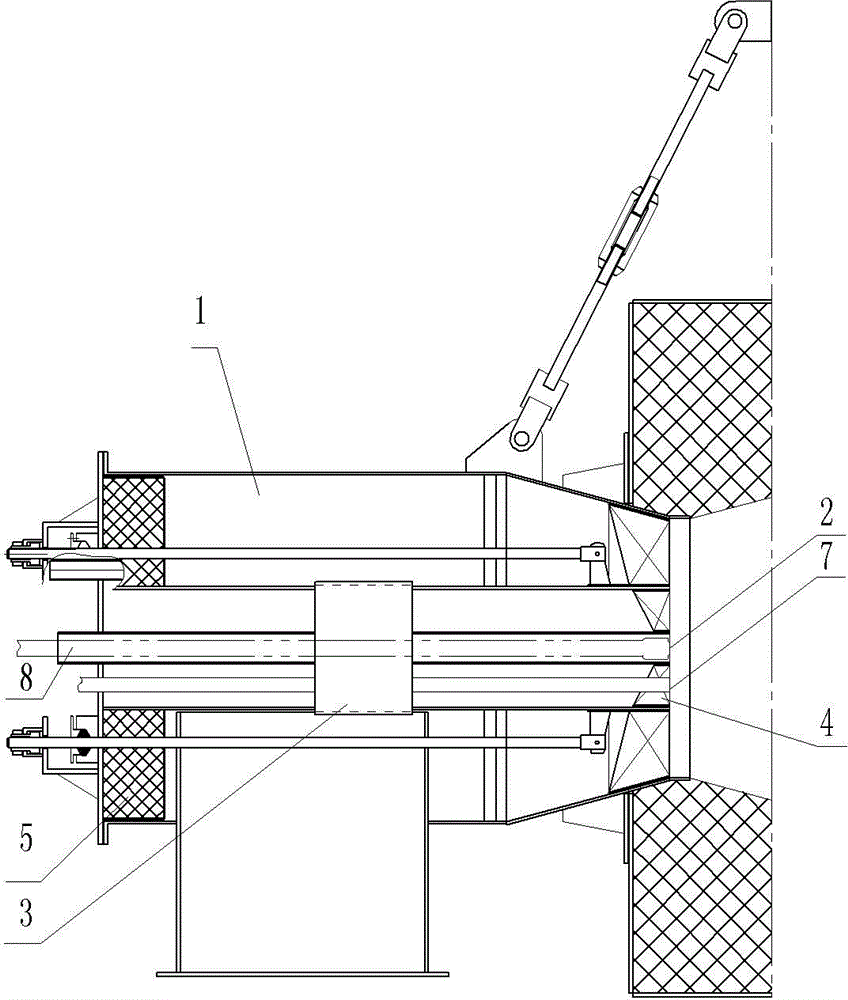

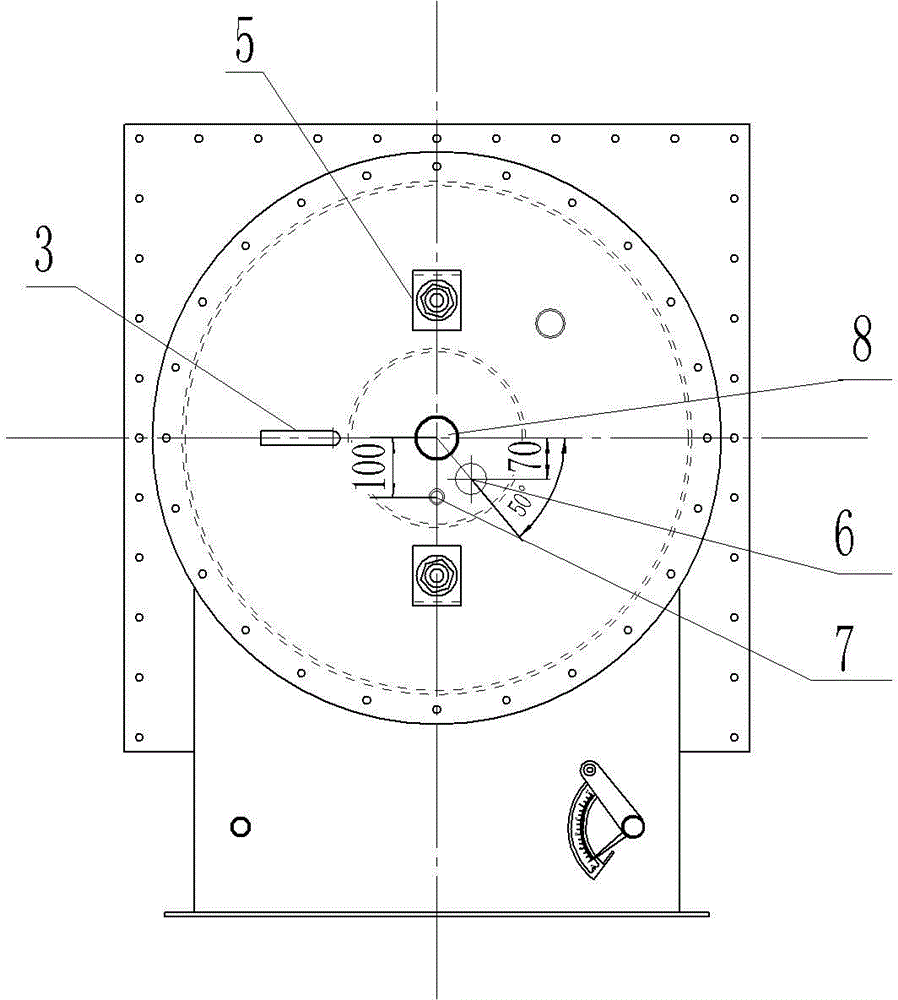

[0011] figure 1 with figure 2 As shown in the heavy oil burner, the air distributor 1 includes a burner 4, a primary air regulator 3 and a secondary air regulator 5; an intermediate hybrid Y-type oil nozzle 2, a high-energy ignition device 6 and an ignition oil gun 7 are arranged in The inner cavity of the air distributor 1; one end of the oil pipe 8 passes into the inner cavity of the air distributor 1 and is connected with one end of the oil nozzle 2; the ignition oil gun 7 is set on the vertical center line of the oil nozzle 2, and its position is from the oil nozzle The horizontal centerline of 2 is 100 mm down; the high-energy ignition device 6 is set on an extension line 50 degrees down from the horizontal centerline of the oil nozzle 2 and 70 mm from the horizontal centerline of the oil nozzle 2.

[0012] This burner adopts two-stage ignition. The high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com