Soilless seedling raising tray and its processing method

A technology of soilless seedling raising and auxiliary materials, applied in soilless cultivation, botany equipment and methods, cultivation, etc., can solve the problems of product air permeability decrease, affect the growth of rice seedlings, and unfavorable seed development, so as to reduce labor intensity and effectively It is beneficial to the growth of plant roots, reducing production costs and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

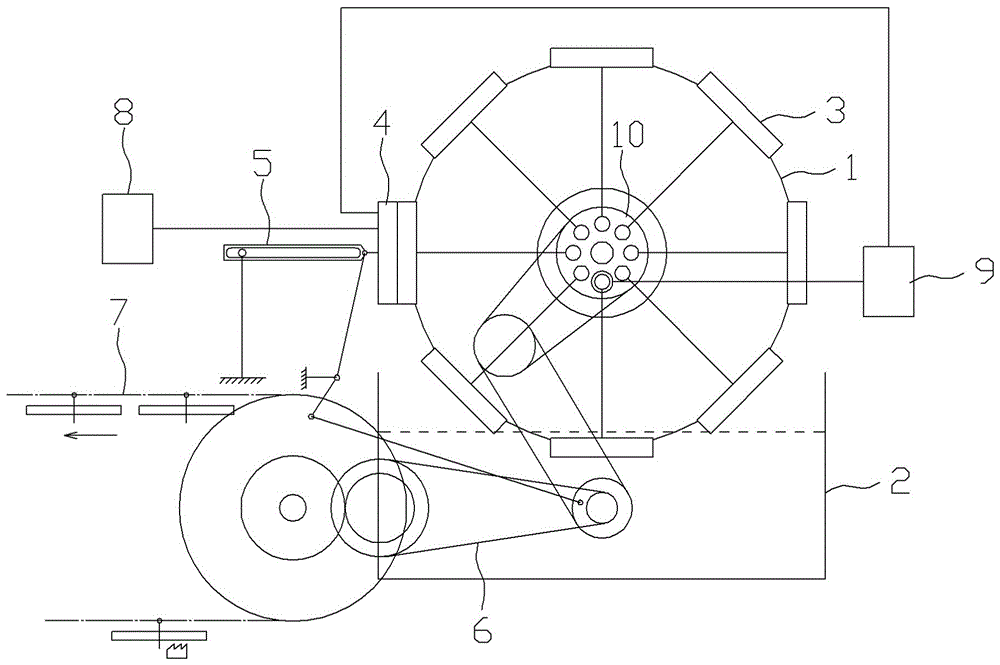

Image

Examples

Embodiment Construction

[0022] Process: main raw material crushing→straw fermentation→ingredient beating→vacuum suction molding→drying→shaping treatment→sticker tray→packaging

[0023] Specific steps:

[0024] Crushing of main raw materials:

[0025] For straw selection, corn straw is selected first, and rice straw is secondly selected; other straws can also be mixed.

[0026] Straw fermentation:

[0027] 1) Straw crushing: Cut the selected straw and other organic matter into 1-2 cm long sections with a grinder.

[0028] 2) Fermentation in large piles: pile the cut straw into large piles. Add a layer of organic fertilizer (no chicken manure) every 50 cm thick, 20 cm thick, use 1 kg of fiber-decomposing bacteria for every 5 cubic meters of straw, one layer of straw and one layer of organic fertilizer and fiber-decomposing bacteria, water thoroughly. If there is no organic fertilizer, 2 kg of urea can be used for every 5 cubic meters of straw.

[0029] 3) Seal the stack: After making a large pile,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com