Automatic cleaning device for glass apparatuses for crude oil production

A glass instrument and automatic cleaning technology, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of operator injury, environmental protection, time-consuming, etc., and improve work efficiency , time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

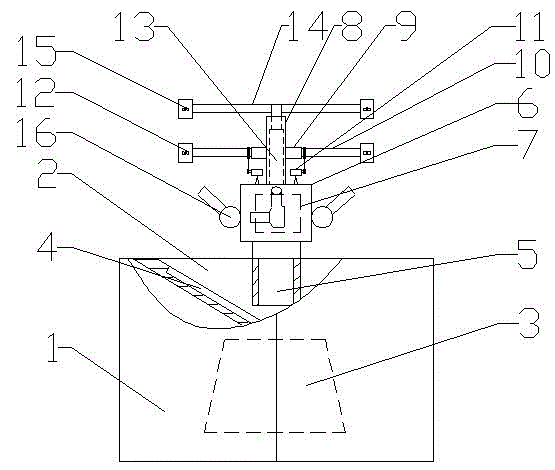

[0014] Accompanying drawing is the specific embodiment of the present invention. like figure 1 As shown, this kind of automatic glass instrument cleaning device for crude oil production includes a hollow working platform 1. The working platform 1 is provided with a door, and the working platform 1 is provided with a conical cleaning basin 2. There is a waste liquid bucket 3, which is located in the working platform 1. The waste liquid bucket 3 has a small mouth and a large bottom, so that when the waste liquid enters the waste liquid bucket 3 through the outlet of the middle part of the cleaning basin 2, the waste liquid can be prevented from splashing. pollute the environment; install a square tube 5 vertically in the cleaning basin 2, there is a gap between the square tube 5 and the cleaning basin 2, the outlet of the cleaning basin 2 is located below the square tube 5, and the upper end of the square tube 5 is connected with a box 6 , the box body 6 is provided with a PLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com