Corridor led light assembly line

An assembly line and LED lamp technology, applied in the direction of assembly machines, material gluing, and connecting components, can solve the problems of low assembly production efficiency and high manual labor intensity, achieve high assembly production efficiency, reduce manual labor intensity, and simplify manual operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

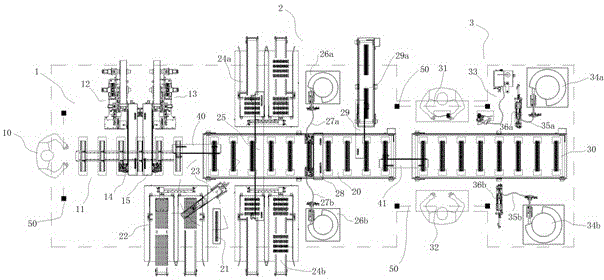

[0014] Such as figure 1 The corridor LED lamp assembly production line of the present invention shown in the present invention includes the first assembly production line 1 for transferring the drawn aluminum and pasting the product serial code on the back of the drawn aluminum, and pasting gaskets on the front of the drawn aluminum, for installing lamp panels on the drawn aluminum, The second assembly production line 2 for reflectors and lenses and the third assembly production line 3 for installing end caps and iron sheets on the two ends of the drawn aluminum respectively. The first assembly line 1 includes a first artificial station 10, a first feeding line 11, a first glue preparation mechanism 12, a second glue preparation mechanism 13, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com