Positioning mechanism

A technology of positioning mechanism and cam mechanism, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high manufacturing cost, low production efficiency, inconvenient operation, etc., to save manufacturing cost and management cost, improve production efficiency, save money artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

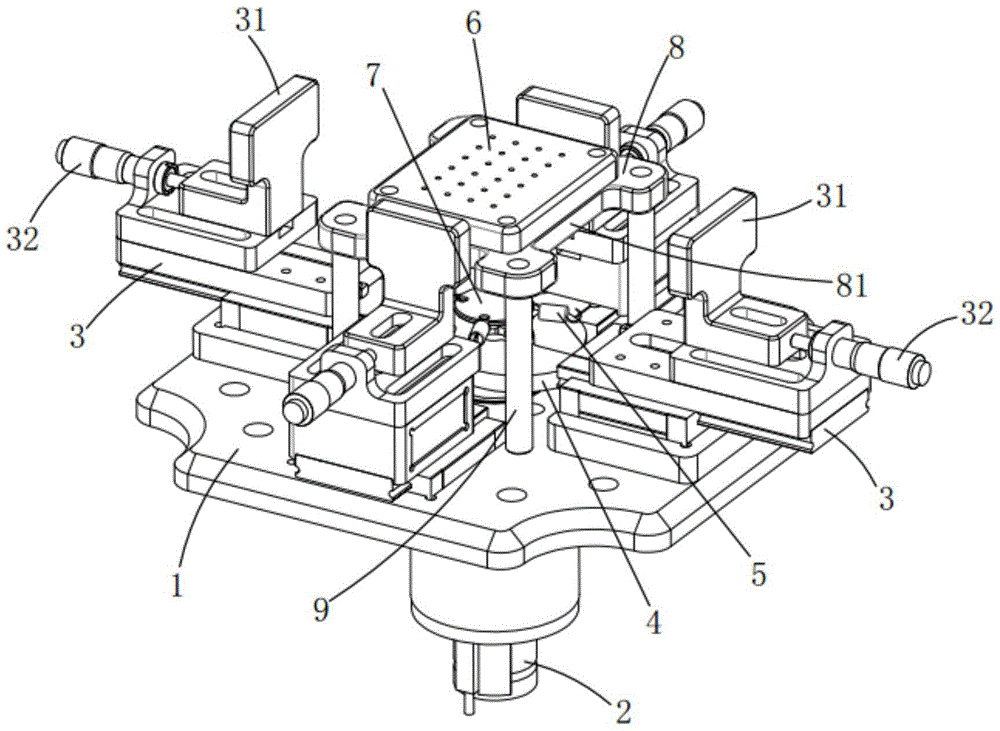

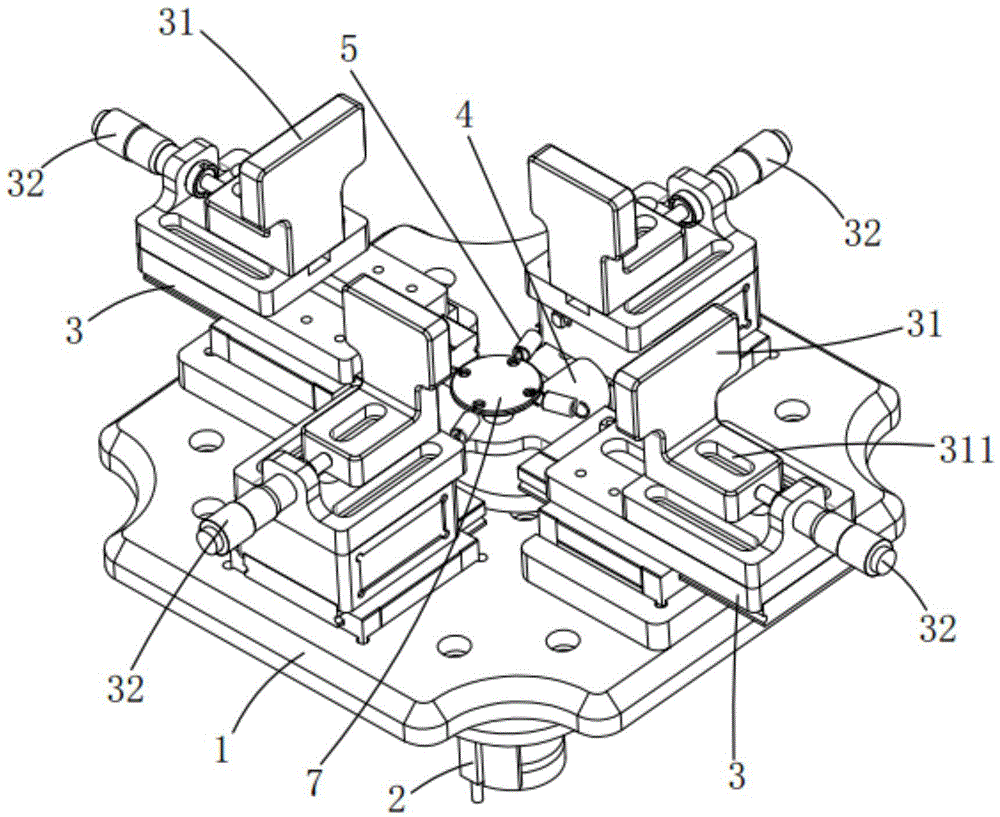

[0018] like figure 1 As shown, a positioning mechanism includes a base plate 1, a power source 2, a sliding module 3, a cam mechanism 4, a telescopic mechanism 5 and a carrying object 6. The base plate 1 is square, and each side of it is provided with a sliding module 3 Positioning push blocks 31 are respectively fixed on the sliding module 3, and a fine-tuning mechanism 32 is installed on its outer edge. , to increase the accuracy and reliability of object positioning; such as figure 2 As shown, the power source 2 is installed on the bottom of the base plate 1, the cam mechanism 4 is arranged in the middle of the base plate 1 and connected with the power source 2, a turntable 7 is fixed on the cam mechanism 4, and four telescopic mechanisms 5 are evenly arranged on the edge of the turntable 7 , each telescoping mechanism 5 is fixedly connected to the inner side of the corresponding sliding module 3; a bearing plate 8 is arranged directly above the turntable 7, and the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com