Pressing and shearing mechanism of corn dog shearing machine

A cutting mechanism, hot dog sausage technology, applied in metal processing and other directions, can solve the problems of difficult cutting and cutting irregularity, increase production cost, large physical size deformation, etc., and achieve the effect of accurate cutting and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

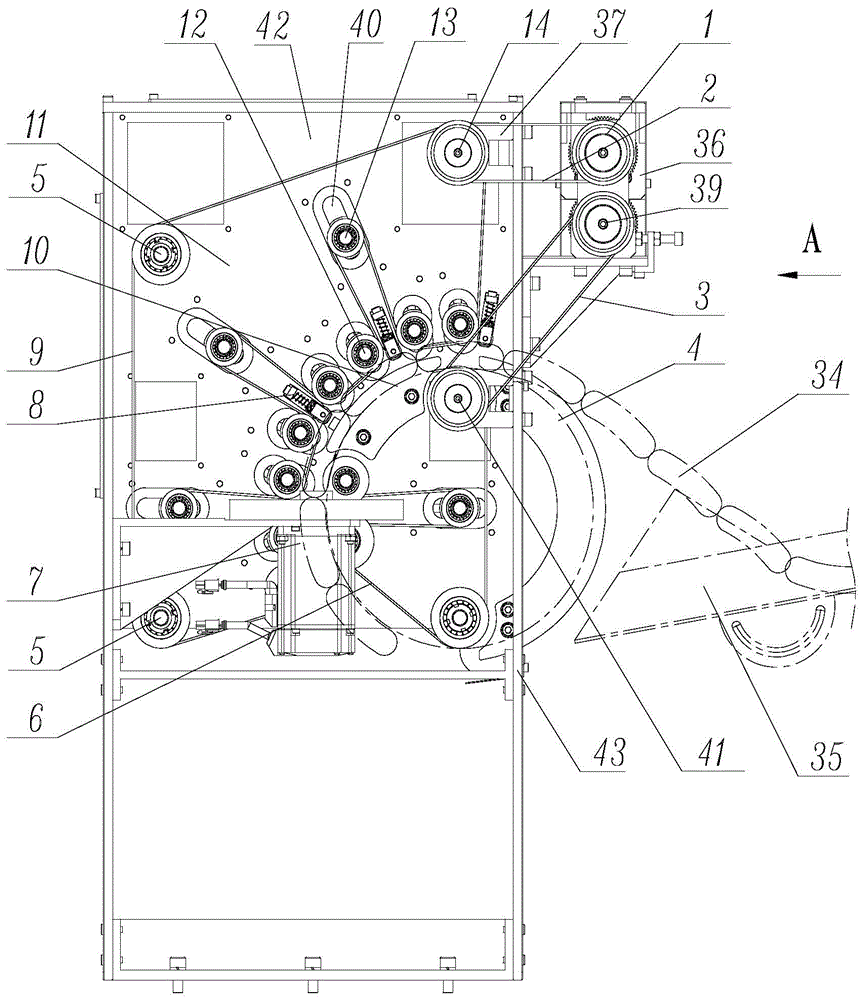

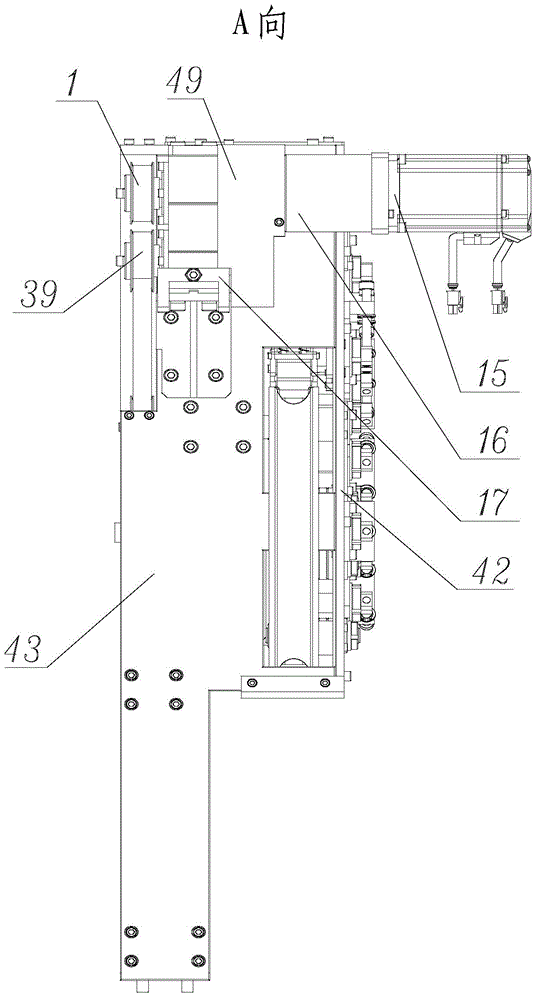

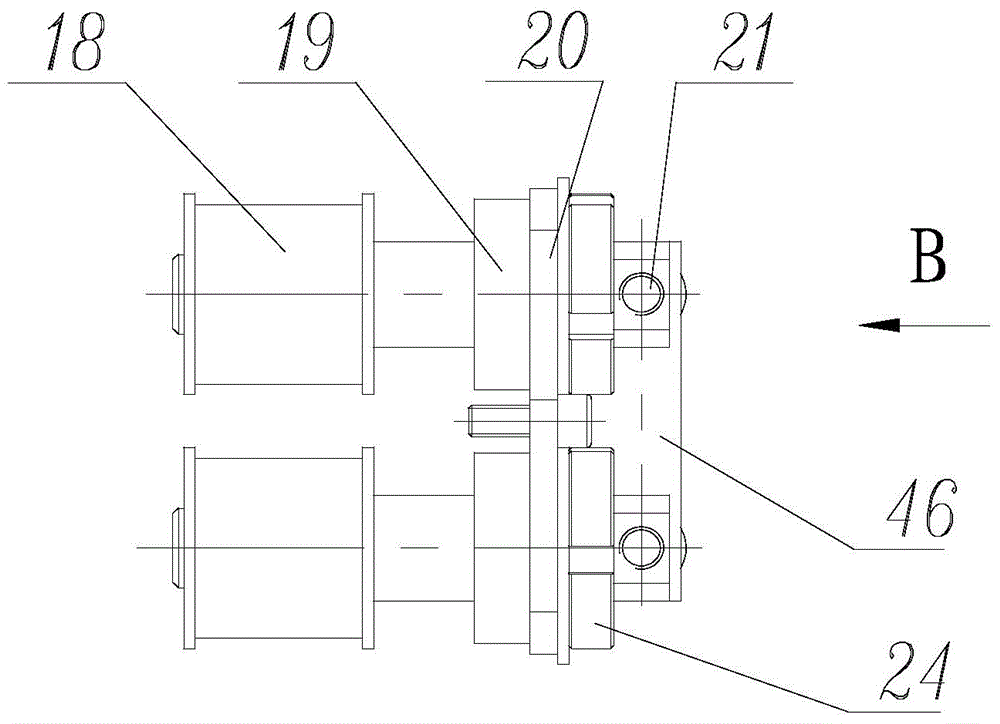

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, the present invention is installed on the frame 11 of the corn dog sausage shearing machine, including two driven wheels 5, a shearing device 7, a pressing assembly 8, a driving belt 9, a timing belt 2, and a double-wheel tensioning mechanism 12. , a single-wheel tensioning mechanism 13, a driving wheel mechanism 14 and a driving device 36, the frame 11 includes a main panel 42 and side plates 43 on both sides, the driving device 36 and the driving wheel mechanism 14 are respectively installed in the machine The rack 11 is located on both sides of the side plate 43 on the input side of the corn dog sausage 34 , and the driving wheel mechanism 14 is arranged in the rack 11 , and the driving wheel mechanism 14 is installed on the rack through the driving wheel bracket 37 On the side plate 43 of the frame 11 , the double-wheel ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com