Tire shoulder pattern structure for tire

A pattern structure and tire shoulder technology, applied in the field of tire shoulder pattern structure, can solve problems such as not easy to discharge, affect the heat dissipation of pattern block 2', weaken the positive impact of traction performance, etc., and achieve the effect of enhancing aesthetics and improving traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

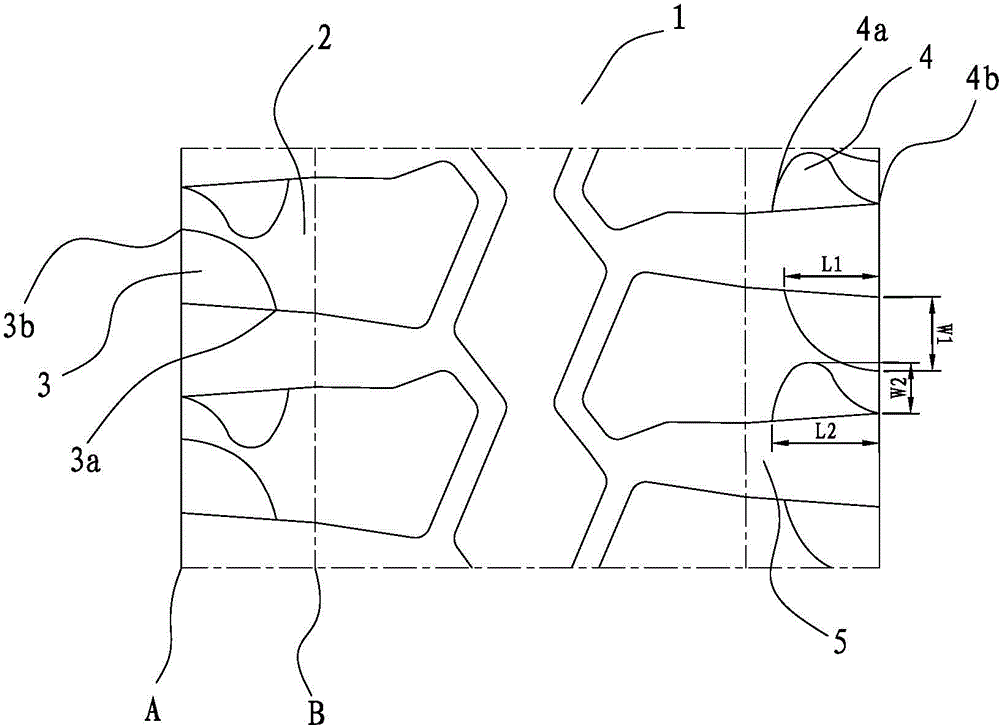

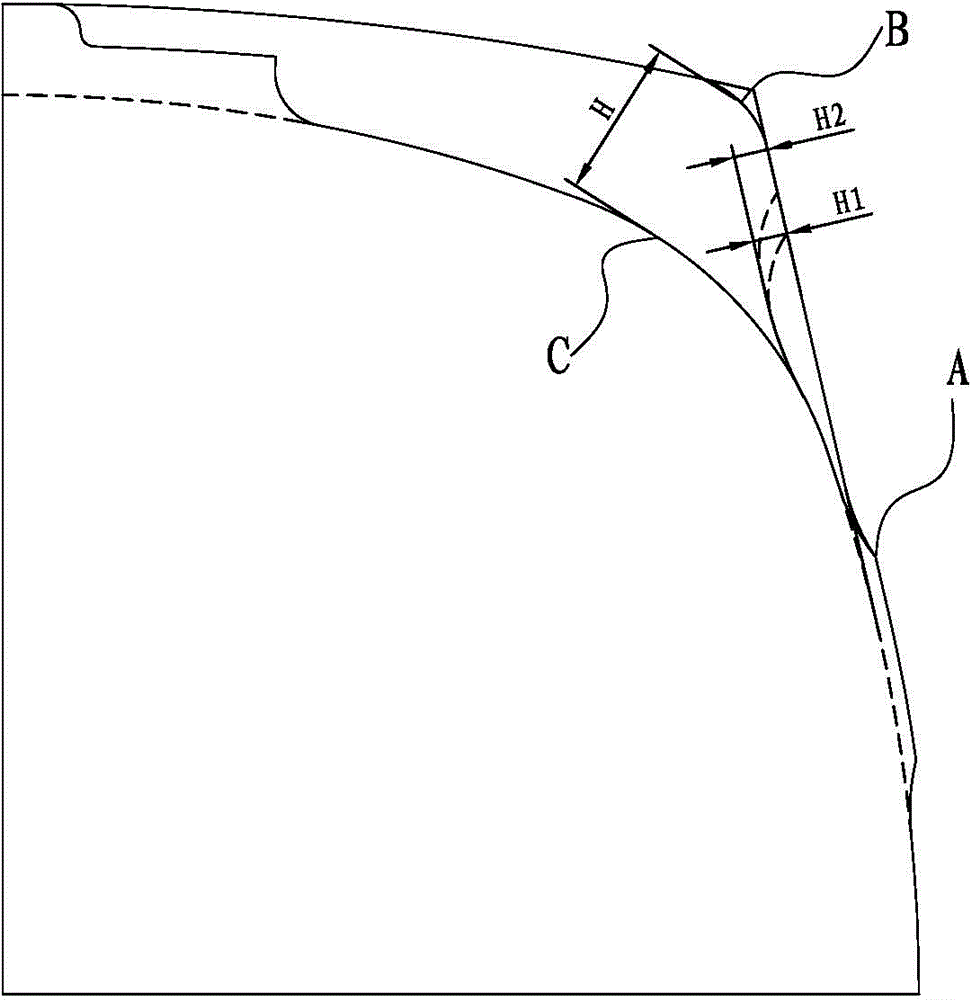

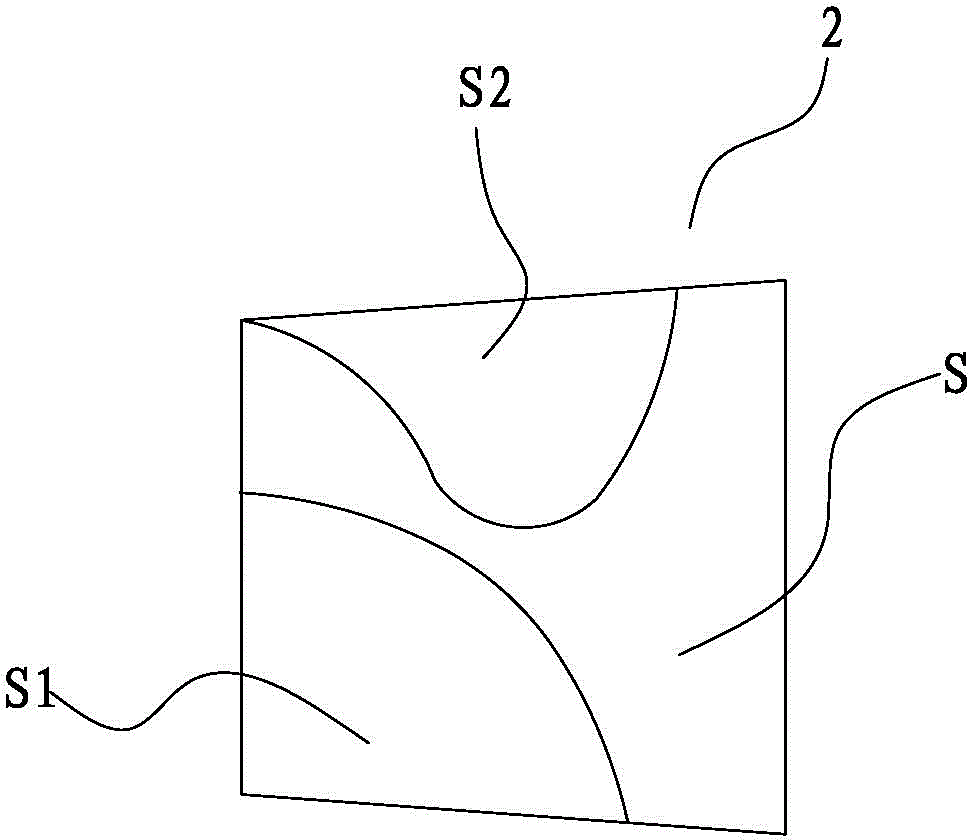

[0024] Such as Figure 1 to Figure 4 As shown, the present invention discloses a pneumatic tire, which includes a tread 1, the tread 1 forms a groove and an integral pattern distributed at intervals in the circumferential direction, and shoulder pattern blocks 2 are formed on both sides of the tread 1; the present invention The key lies in:

[0025] The shoulder pattern blocks 2 extending to the pattern on the upper sidewall are arranged front and rear with mud forward traction grooves 3 and mud ground reverse traction grooves 4; It is set forward or reverse symmetrically; wherein the mud forward traction groove 3 is formed from the outer edge A and the side edge of the shoulder block 2 into the pattern block with at least a circular arc; the mud reverse traction groove 4 is formed from the shoulder The outer edge A and the other side edge of the pattern block 2 are formed with at least one arc in the pattern block. In this way, the traction performance, heat dissipation eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com