An assembly structure of an integrally sealed underwater vehicle

An underwater vehicle body and overall sealing technology, which is applied to underwater operation equipment, transportation and packaging, ship parts, etc., can solve problems such as the inability to visualize the operating status of instruments and equipment, the impact of troubleshooting, and damage to the debugging environment, etc., to achieve benefits Debugging and troubleshooting, the effect of facilitating debugging and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

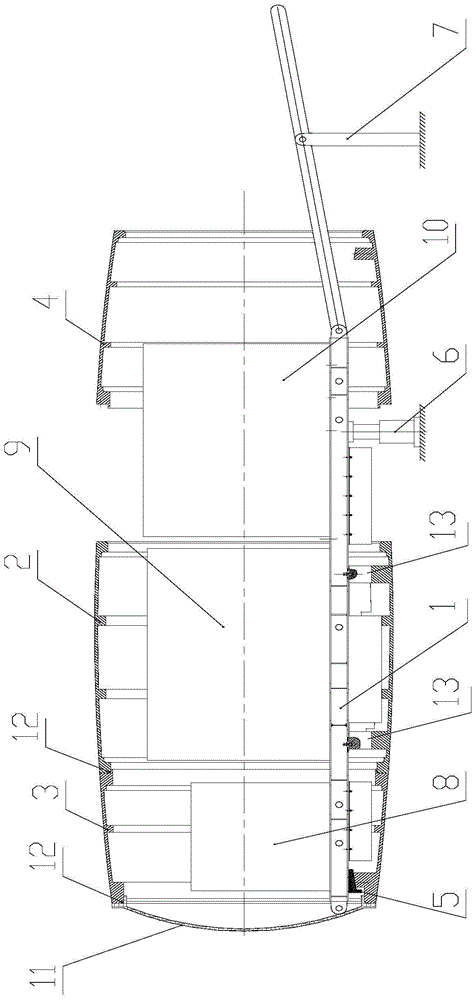

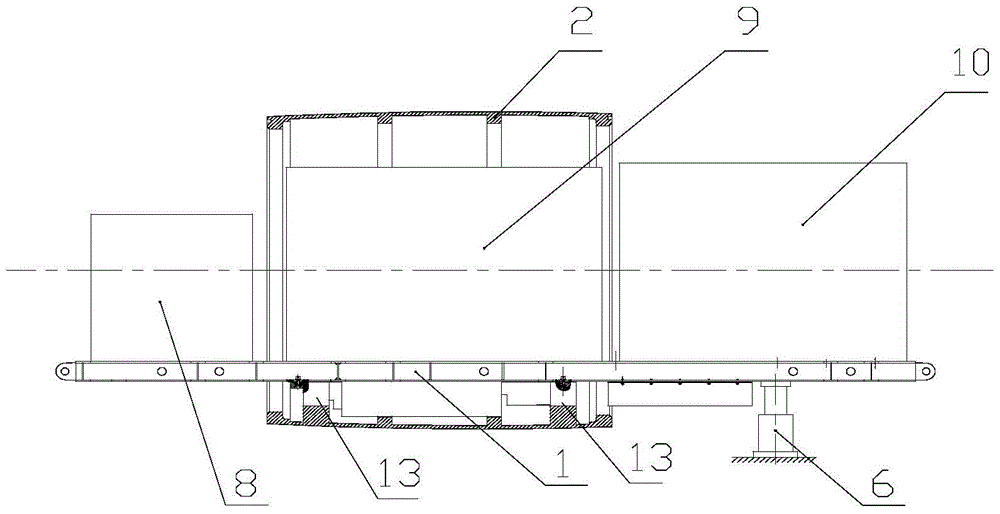

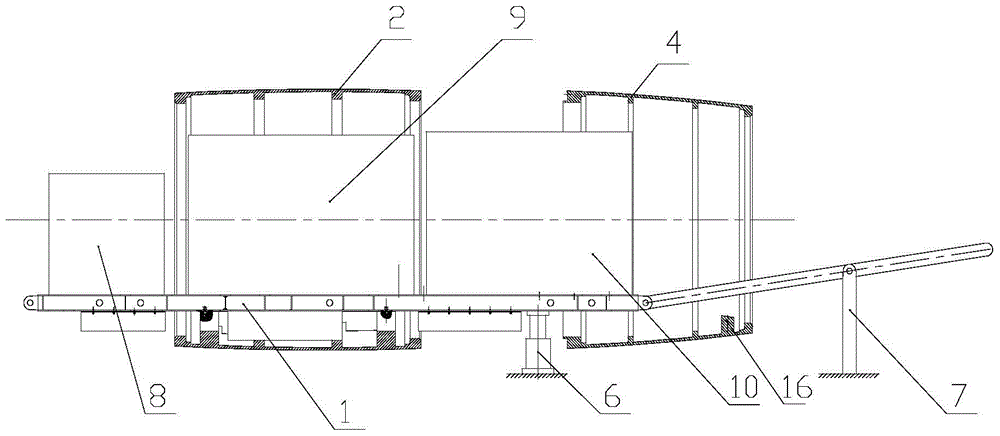

[0021] Such as Figure 1~2 As shown, the present invention includes a common underframe 1, a central cabin section 2, a first connecting cabin section 4, a second connecting cabin section 3, a first assembly tool 6, a second assembly tool 7, a wedge iron support 5 and an end cover 11 , wherein the central cabin section 2 is a hollow structure penetrating in the axial direction, and a support 13 is provided on the inner bottom surface of the central cabin section 2, and the common chassis 1 is installed on the support 13, and the Both ends of the common underframe 1 protrude to the outside of the central cabin section 2 along the axial direction parallel to the central cabin section 2 . The first connecting cabin section 4 and the second connecting cabin section 3 are respectively hollow structures penetrating along the axial direction of itself, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com