Brick storage system for semi-finished bricks and brick storage method

A semi-finished product and brick storage technology, which is applied in the field of semi-finished brick storage system, can solve the problems of limited number of wire rack storage bricks, large wear of the wire rack belt, and uneven force on the belt. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

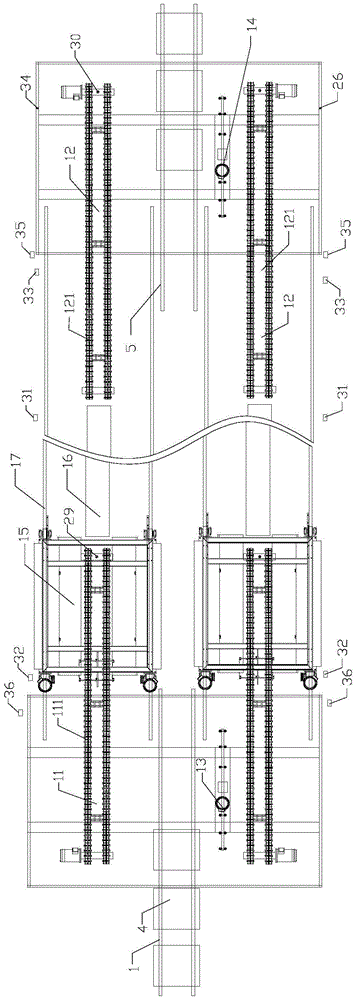

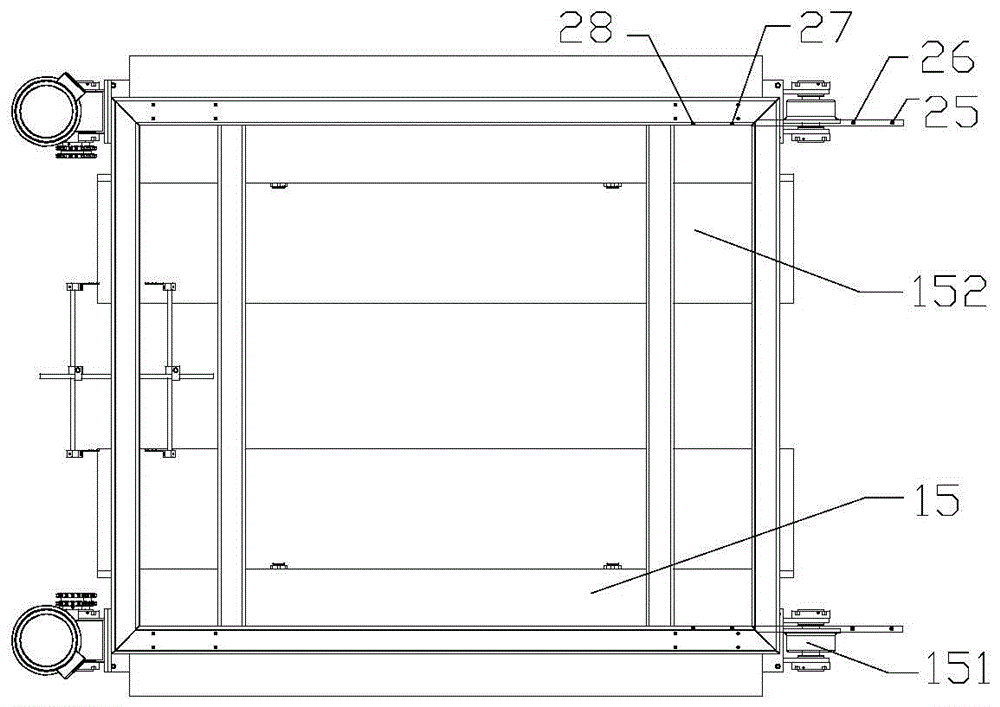

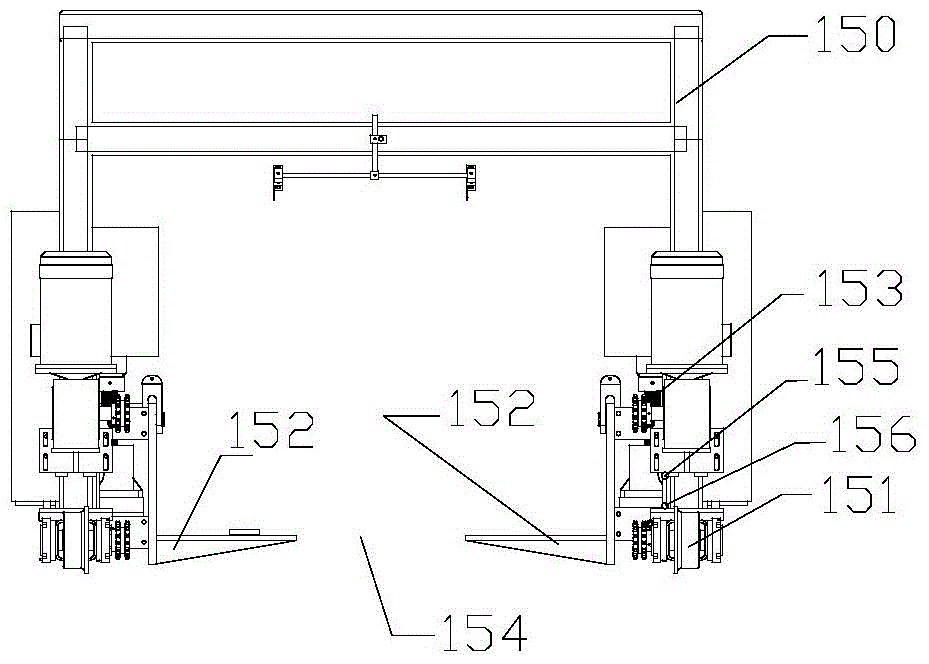

[0038] refer to figure 1 , the brick storage system for semi-finished bricks according to the present invention, which includes a first brick storage chain group 11, a second brick storage chain group 12, a brick lowering machine 13, a brick loading machine 14, a transfer trolley 15, a brick storage pier 16 and controller. Among them, the first brick storage chain group 11 is used to transport the bricks picked up from the production rack to the brick storage pier 16, and the second brick storage chain group 12 is used to transport the bricks picked up from the brick storage pier 16 to the polishing machine , as spares for each other, one group stores bricks, and the other group loads bricks. The first brick storage chain group 11 and the second brick storage chain group 12 each include two parallel storage brick chains 111, and each storage brick chain 111 includes two 6-meter-long 2-inch row chains, which are driven by a motor , the row chain has a strong bearing capacity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com