Preparation process of primer material with moisture permeability

A primer material and preparation process technology, applied in the field of textile fabrics, can solve the problems of difficulty in breaking through 3500MMH2O, insufficient surface toughness of the coating film, low A-grade rate of finished products, etc., to improve the moisture permeability, proper permeability, and activity. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: a kind of primer material preparation process with moisture permeability function, comprising:

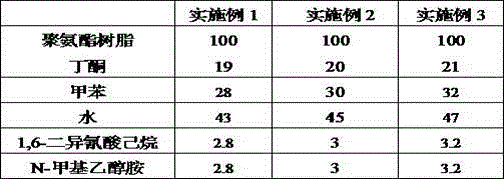

[0022] Step 1. Mix methyl ethyl ketone, water and polyurethane resin according to the mass ratio of 66~68:3~5:29~31 to form the main resin solution. Note: the mixing ratio of Example 1 is 66:3:31, Example 2 The mixing ratio is 67:5:29, and the mixing ratio of Example 3 is 68:4:30;

[0023] Step 2, adding N-methylethanolamine as an accelerator in the main resin solution of step 1, the mass ratio of the main resin solution and the accelerator is 100:2.5 or 3 or 3.5;

[0024] Step 3: Slowly put the mixture of methyl ethyl ketone and toluene into the main resin solution in step 2 and stir evenly to form a main resin mixed solution. The mass ratio of this mixed solution to the main resin solution is 100:43 or 44 or 45, so Butanone and toluene form the mixed solution according to the mass ratio of 1:2 or 1:1;

[0025] Step 4. Stir the mixed solution of hexahexanediis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com