Loading device and loading-device-based seismic test system for beam-column joint

A technology of loading device and beam-column joint, which is applied in the direction of measuring device, machine/structural component test, vibration test, etc., to avoid axial displacement and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

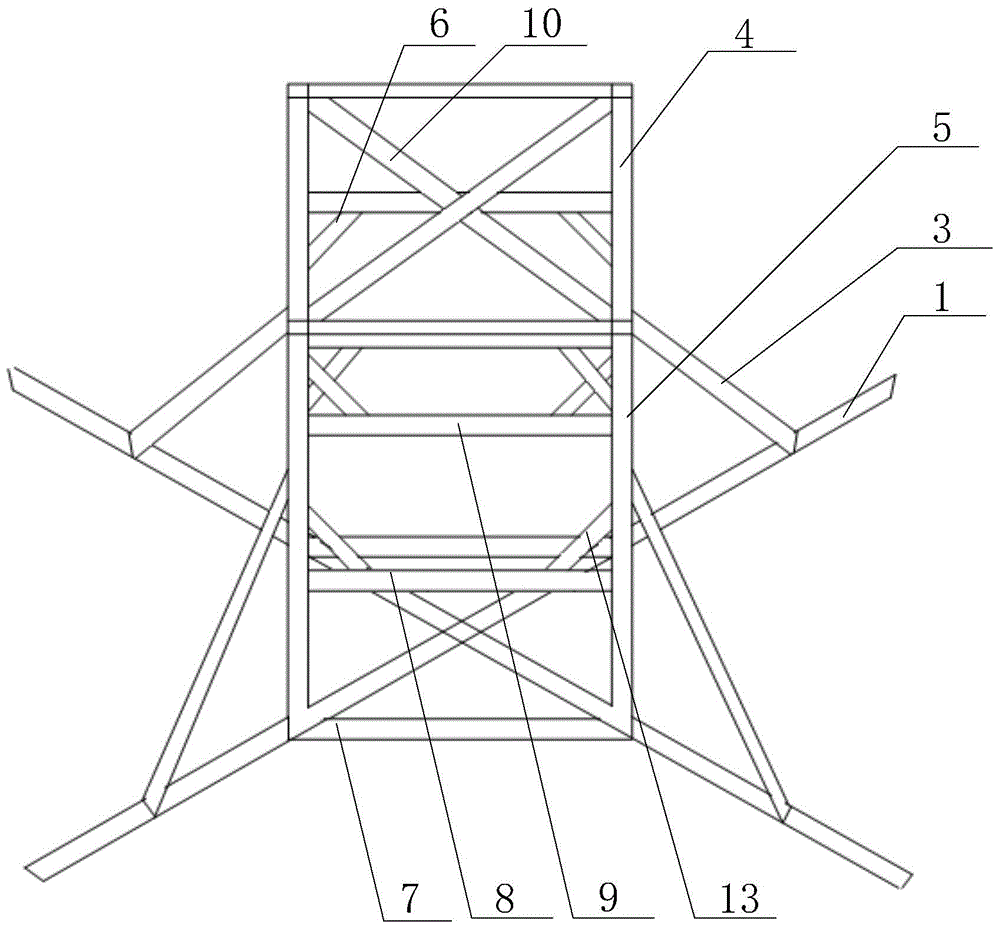

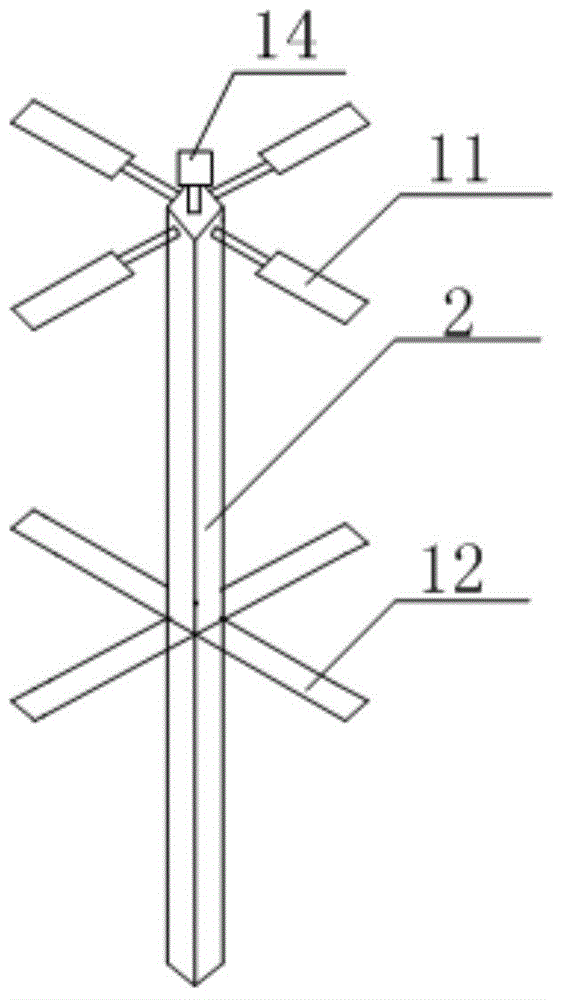

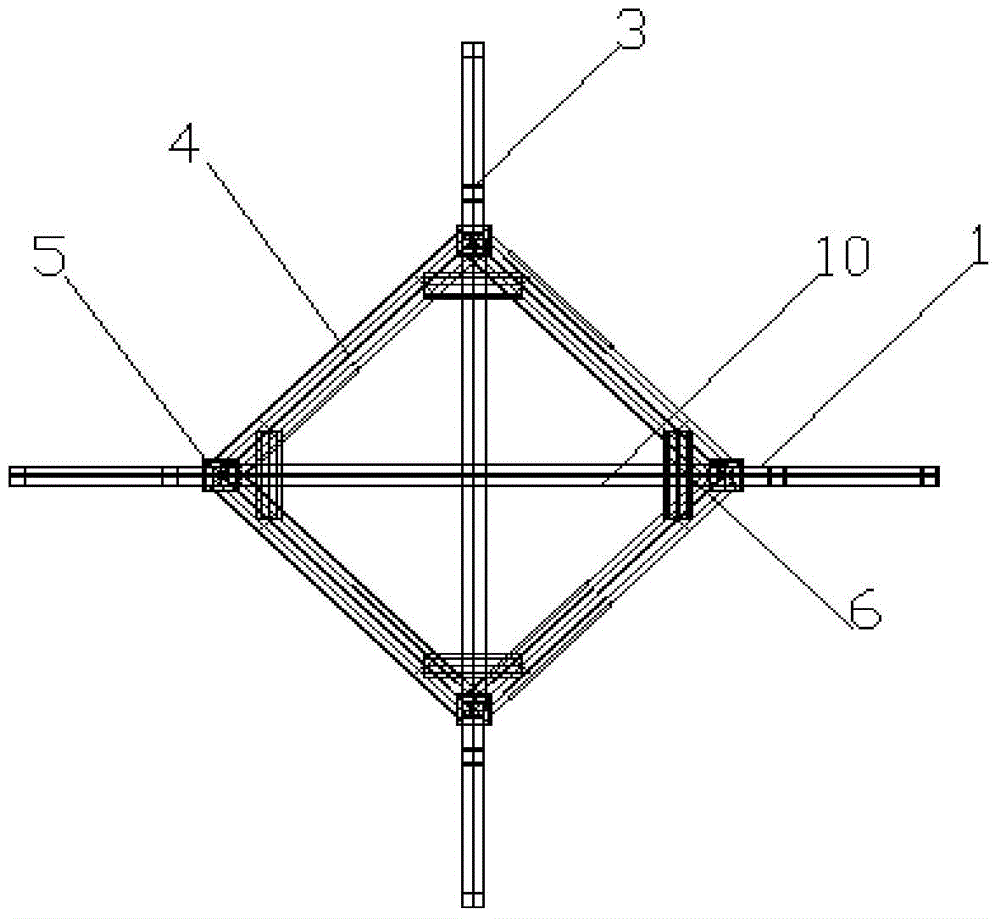

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the loading device of the present invention comprises an X-shaped base, four reaction frame square steel pipe columns 5, four first reaction frame beams 4, four second reaction frame beams 9, four third reaction frames Crossbeam 8, four short inclined beams 6 of the first reaction frame, four short inclined beams 13 of the second reaction frame, two first steel beams 10; the X-shaped base is composed of two cross-distributed second steel beams 1 , the lower ends of the four reaction frame square steel pipe columns 5 are respectively fixed on both sides of the two second steel beams 1; the two ends of the first reaction frame beam 4, the two ends of the second reaction frame beam 9, the third Both ends of the reaction frame crossbeam 8 are respectively connected to the sides of two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com