Working steps of optical disc driver testing device

A technology of optical disc drive and working steps, which is applied in electronic circuit testing, instruments, measuring electricity, etc., can solve the problems of missing pins of sockets, lowering the yield of factory products, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

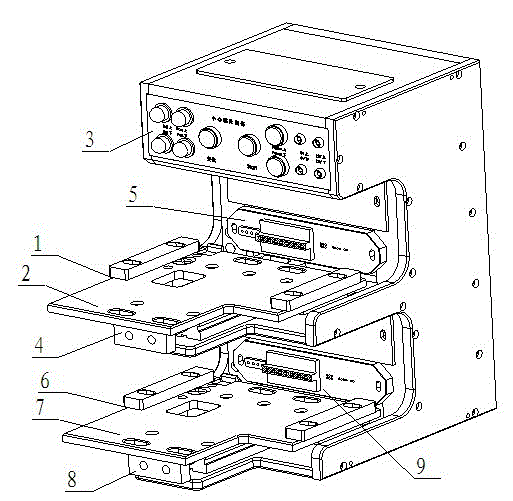

[0008] see figure 1 , the embodiment of the present invention includes:

[0009] A kind of working steps of optical disc drive testing machine, its working steps are: the first step is to place the optical disc drive on the optical disc drive mounting plate 2 of the upper optical disc drive loading mechanism 1, position it through the left positioning bar and the right positioning bar, and position it through the square The clamping hole is fixed, the second step is to press the upper start button of the detection control circuit 3, the slide cylinder 4 of the upper optical disc drive loading mechanism 1 moves, and the optical disc drive is connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap