Optical disc driver testing device

A technology of optical disc drive and testing machine, which is applied in electronic circuit testing, instruments, measuring electricity and other directions, can solve the problems of missing pins of sockets, inaccurate detection, and lowering the yield of factory products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

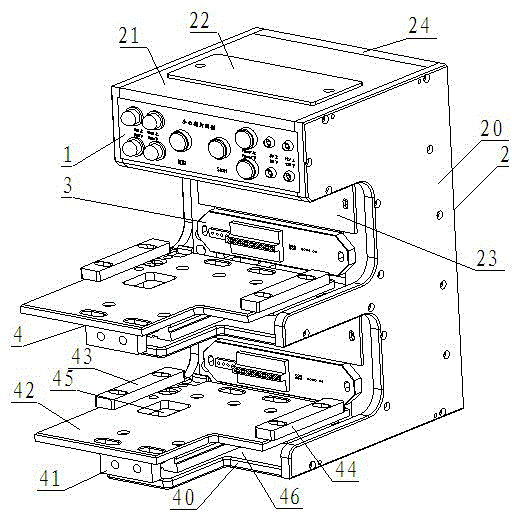

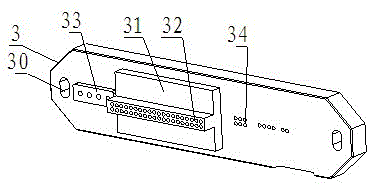

[0012] see figure 1 with figure 2 , the embodiment of the present invention includes:

[0013] An optical disc drive testing machine, the optical disc drive testing machine includes a detection control circuit 1, a detection seat 2, a line plate pin detection board 3 and a CD drive loading mechanism 4, the detection control circuit 1 is installed on the upper part of the detection seat 2, The lower part of the detection seat 2 is also equipped with two optical disk drive loading mechanisms 4 stacked up and down, and the detection seat 2 is also provided with a line plate pin detection board 3 corresponding to the position of each optical disk drive loa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap