Automatic measurement method for separated-out particles in steel and morphology classification method thereof

A technology of automatic measurement and morphological classification, applied in measuring devices, image analysis, particle size analysis, etc., can solve problems such as low precision and low efficiency, and achieve excellent universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

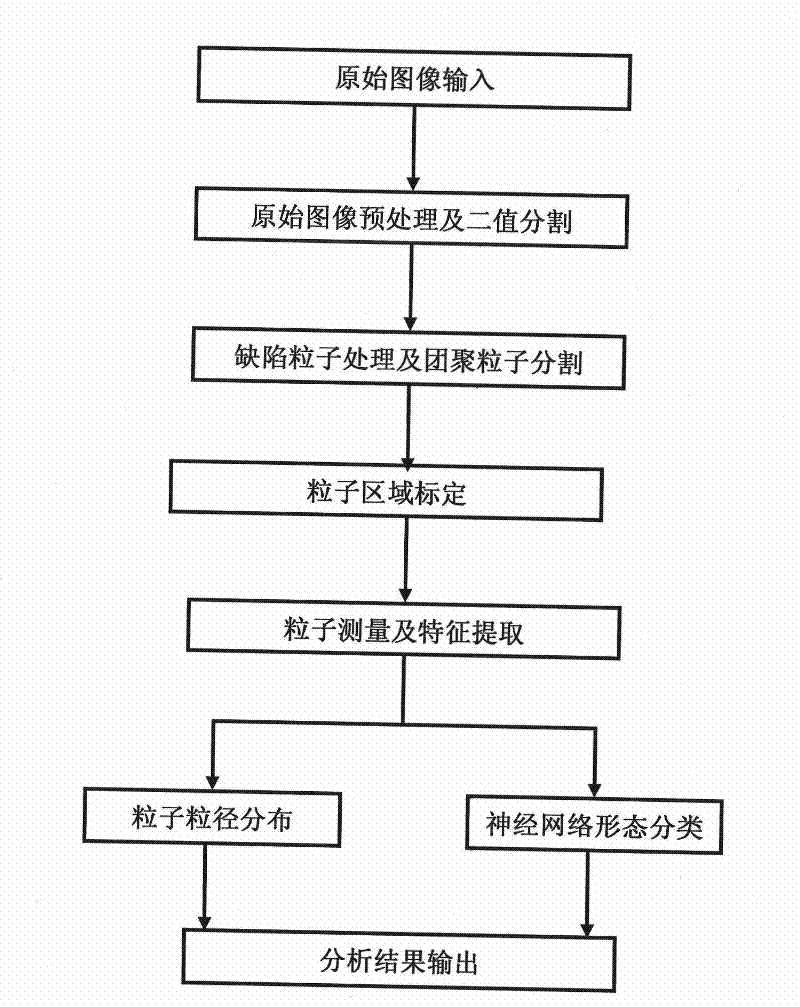

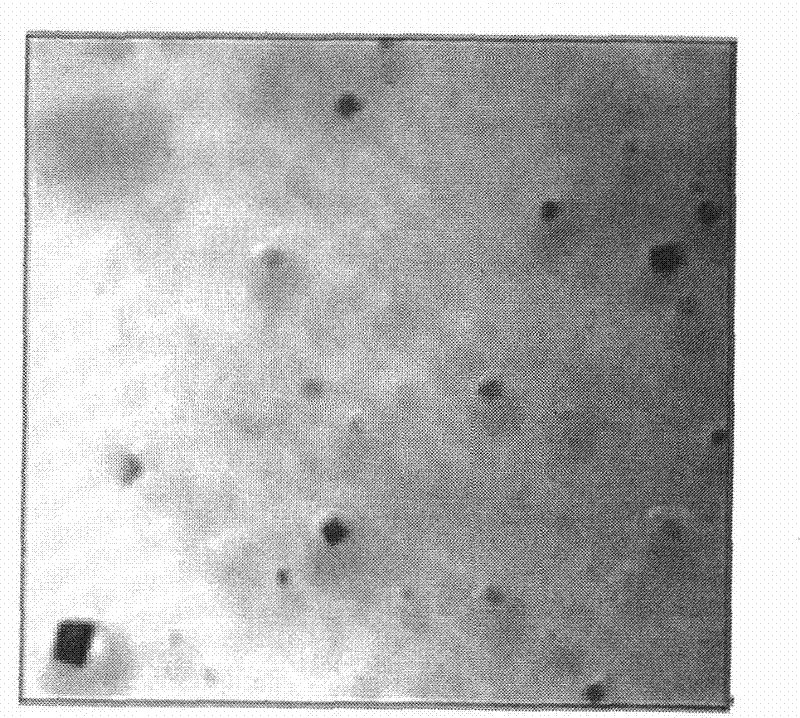

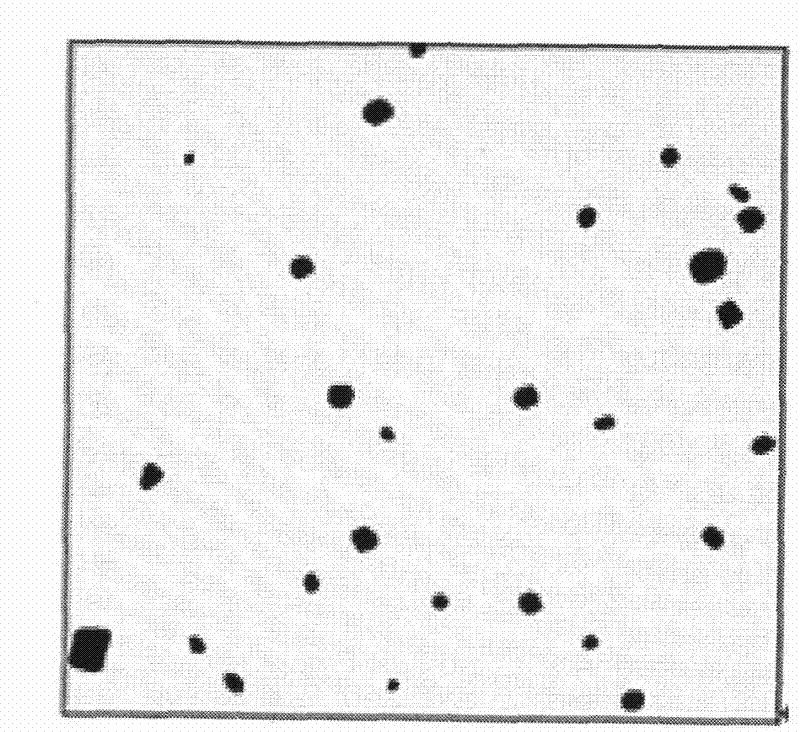

[0033] Such as figure 2 As shown, first to figure 2 The original image is preprocessed. First, the median filter method is used to smooth the image to remove the noise brought to the precipitated particle image during film production or acquisition, and then the contrast of the image is increased through gray balance processing. In view of the fact that the present invention only involves the determination of the morphological characteristics of the precipitated particles, that is, the separate analysis of the precipitated particles in the image has nothing to do with the color information, so binary segmentation can be performed on it to obtain a black and white template that completely separates the precipitated particles from the background, That is, the binary image of the particle. Due to the diversity and complexity of the images of precipitated particles in steel, the gray contrast value between the particles and the background is very constant, and the multi-region ...

Embodiment 2

[0113] Place Figure 8 The image shown in this image has a large number of precipitated particles and a complex background. Concrete processing procedure of the present invention is: first to Figure 8 The target image shown is preprocessed, the holes are filled by morphological filtering and the improved seed filling method is used, and the agglomerated particles are segmented by using the empirical criterion threshold value, thereby restoring the real shape of the target particles, and obtaining Figure 9 The effect diagram after binary segmentation, morphological filtering and defect particle processing is shown. On this basis, the particle measurement and particle shape classification statistics are carried out, and then the particle size distribution of the precipitated particles is obtained as follows: Figure 10a The morphological distribution of the precipitated particles is shown as Figure 10b As shown, the particle size measurement and analysis results are shown ...

Embodiment 3

[0117] Such as Figure 11 The image shown has stuck particles and a lot of background noise. The specific processing process of the present invention is as follows: firstly, the target image is preprocessed, the holes are filled through morphological filtering and the improved seed filling method is used, and the agglomerated particles are segmented by applying the empirical criterion threshold, thereby restoring the true shape of the target particles, Got Figure 12 The binary segmented and morphologically filtered image shown, and Figure 13 The effect diagram after binary segmentation, morphological filtering and defect particle processing is shown. On this basis, the particle measurement and particle shape classification statistics are carried out, and then the particle size distribution of the precipitated particles is obtained as follows: Figure 14a The morphological distribution of the precipitated particles is shown as Figure 14b As shown, its particle size measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com