Gluing detection device for screws

A glue detection and screw technology, applied in the field of visual inspection, can solve the problems of unable to meet the high output of the factory, affect the detection results, and low labor efficiency, and achieve the effect of stable work, accurate detection results and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

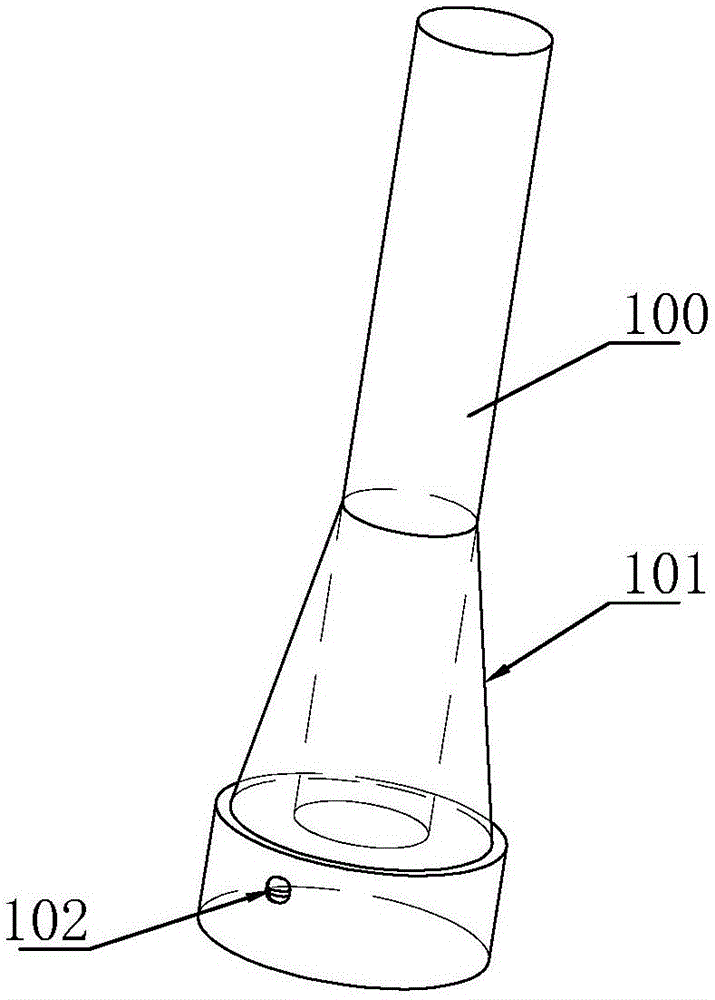

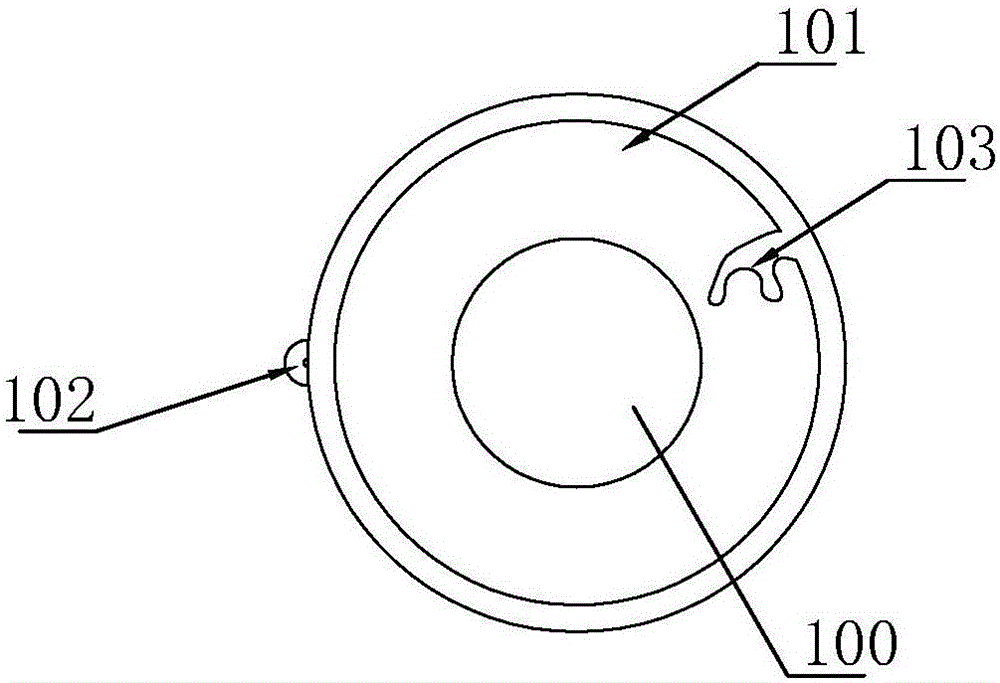

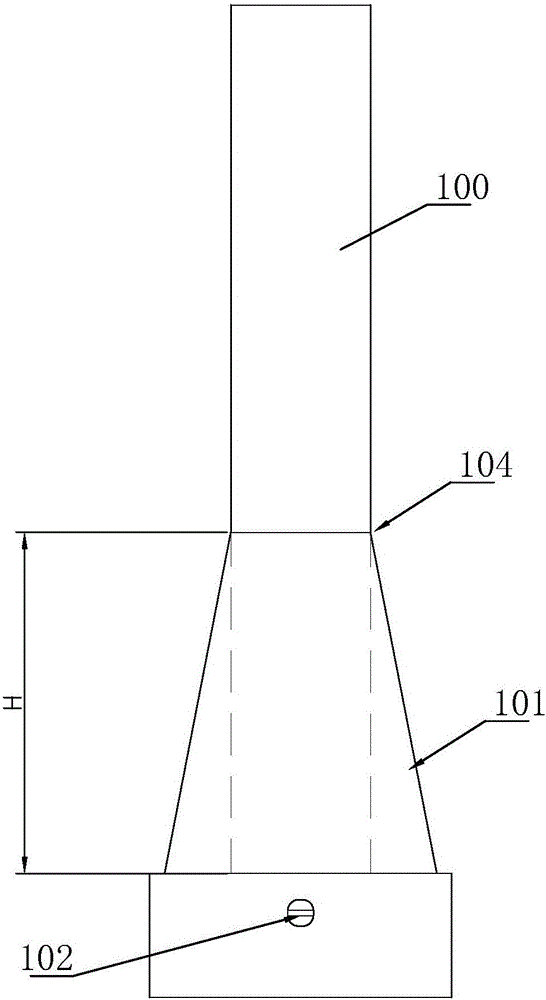

[0026] Such as Figure 1 to Figure 3 As shown, when applying glue 101 to screws 100 in large quantities, due to operational and process problems, sometimes glue will appear on the head of screw 100, that is, the glue part 102 shown in the figure; There is a lack of glue on the seat surface of the head of 100, that is, the lack of glue 103 shown in the figure. These situations need to be avoided. In order to eliminate the glue-coated screws 100 with these defects, the following glue-coating detection device is used for detection. The following glue-coating detection device can also detect the glue height H of the glue on the screw 100 .

[0027] Such as Figure 4 to Figure 7 As shown, a screw gluing detection device according to the present invention includes a transmission mechanism (not shown) for transmitting the screw 100, a side-view image acquisition mechanism for collecting the gluing in the side-view direction of the screw 100, and A top-view image collection mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com