Surface dyeing inspection method of sapphire crystal bar

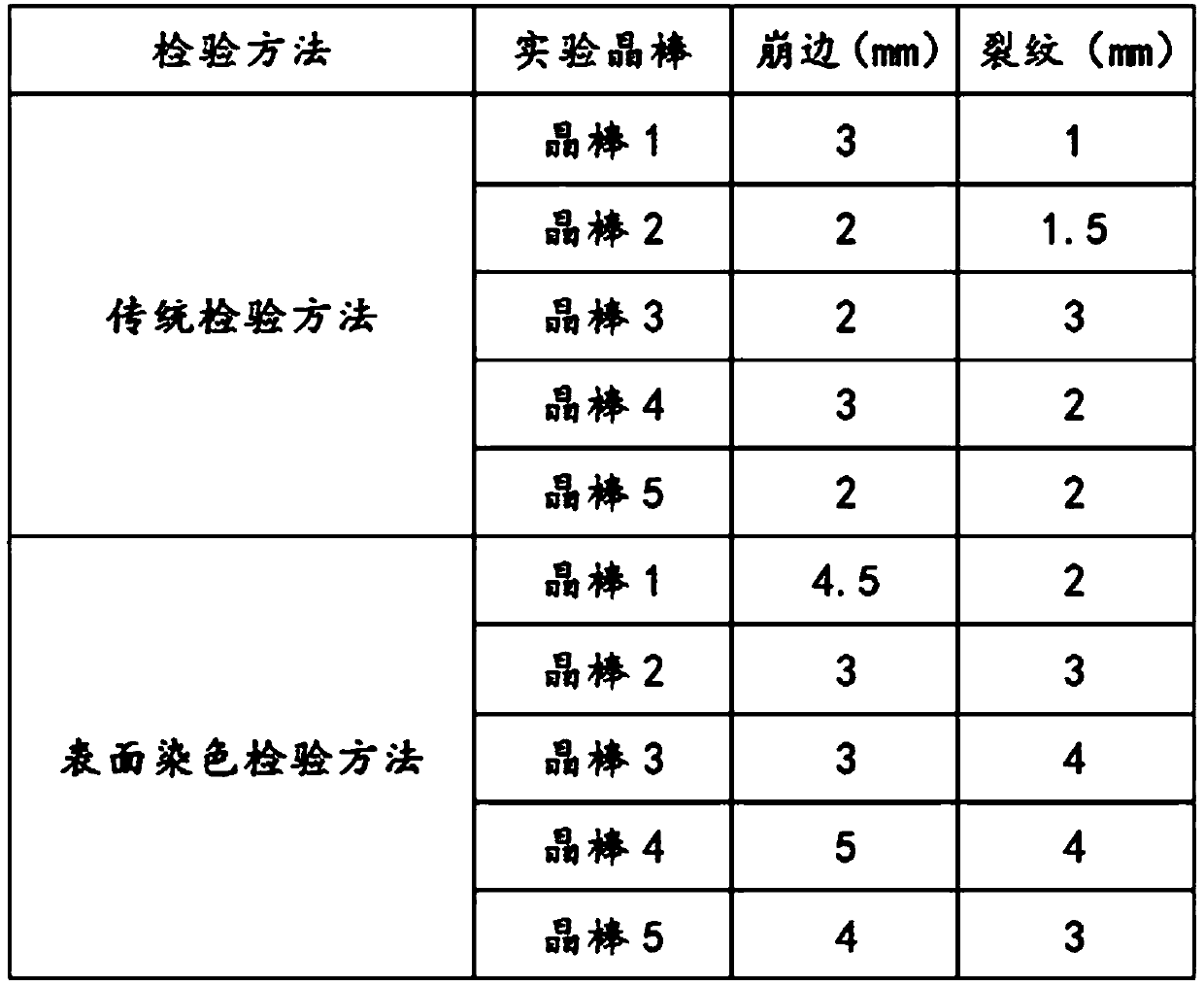

A surface dyeing and sapphire technology, which is applied in the preparation of test samples and optical testing for flaws/defects, etc., can solve problems such as low efficiency, human injury, crack cracking and missing inspection, and achieve high efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for surface dyeing inspection of sapphire crystal rods includes the following steps:

[0021] 1. Thoroughly clean the dust, grease and other impurities on the surface of the sapphire crystal bar to be inspected with a washing liquid, and then dry it completely after washing;

[0022] 2. Spray red penetrant evenly on the surface of the crystal rod to be inspected after drying, the penetration time is 3 to 4 minutes; after an interval of 5 minutes, repeat the above actions again to ensure the effective penetration time is 9-15 minutes;

[0023] 3. After the infiltration treatment is completed, use a dust-free cloth to remove the residual permeate, and then wipe it with a dust-free cloth containing detergent;

[0024] 4. After thoroughly removing the red penetrant after penetration, apply the white developer evenly on the surface of the crystal rod. The white developer after the application dries quickly and shows white, penetrating the penetrating liquid at the crack edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com