Encapsulation shell structure with double rows of pins extending from side surfaces

A technology of encapsulating shells and double-row tubes, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of poor heat dissipation and inability to meet the needs of SIP systems, and achieve the effect of increasing the number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

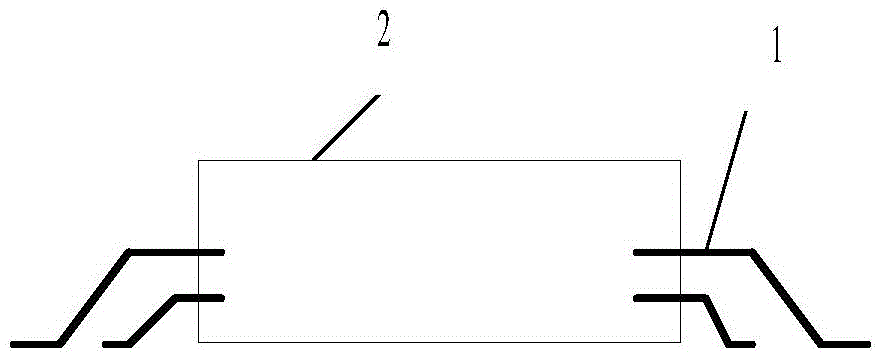

[0010] like figure 1 As shown, a package shell structure with double rows of pins drawn from the side includes a flat shell 2, two rows of pins 1 are drawn from the side of the flat shell 2, and the pins 1 are drawn downwards, and the end is flat with the bottom of the flat shell 2. together. The two rows of pins 1 have a pitch of 2.54 mm between the pins in each row, totaling 20 pins; the pitch between the two rows is also 2.54 mm, and the horizontal difference between the second row and the first row is 1.27 mm. Ensure that each pin can be connected to the substrate using gold wires during internal assembly.

[0011] Compared with the original scheme, the present invention doubles the number of pins without increasing the area, and is suitable for complex integrated systems such as SIP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com