Extrusion cylinder with guiding cooling or heating medium

A technology of heating medium and rollers, applied in material forming presses, manufacturing tools, presses, etc., can solve problems such as inability to use pins, deterioration of the extrusion process, error-prone extrusion rollers, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

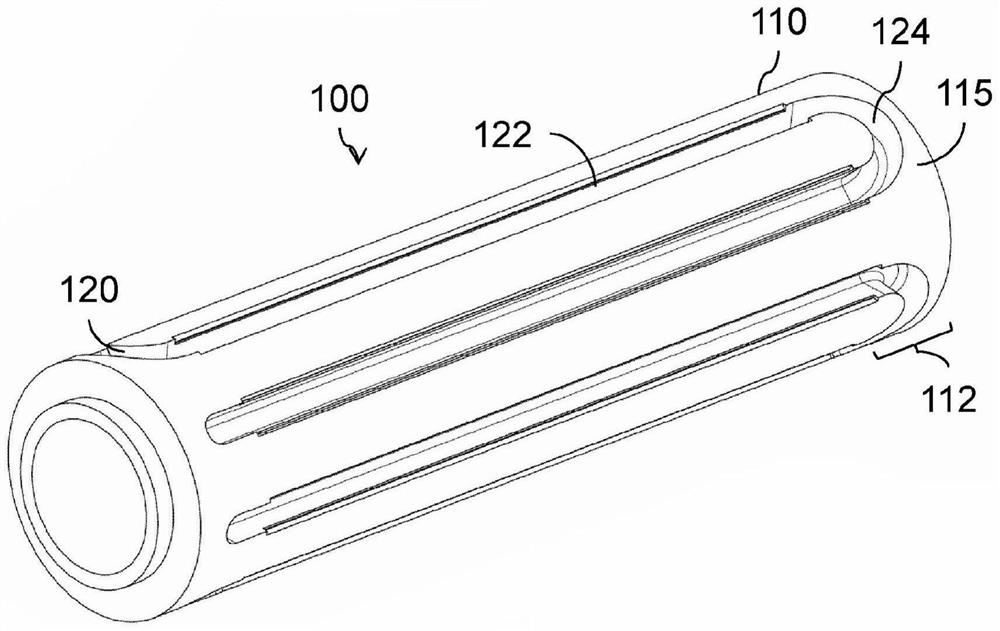

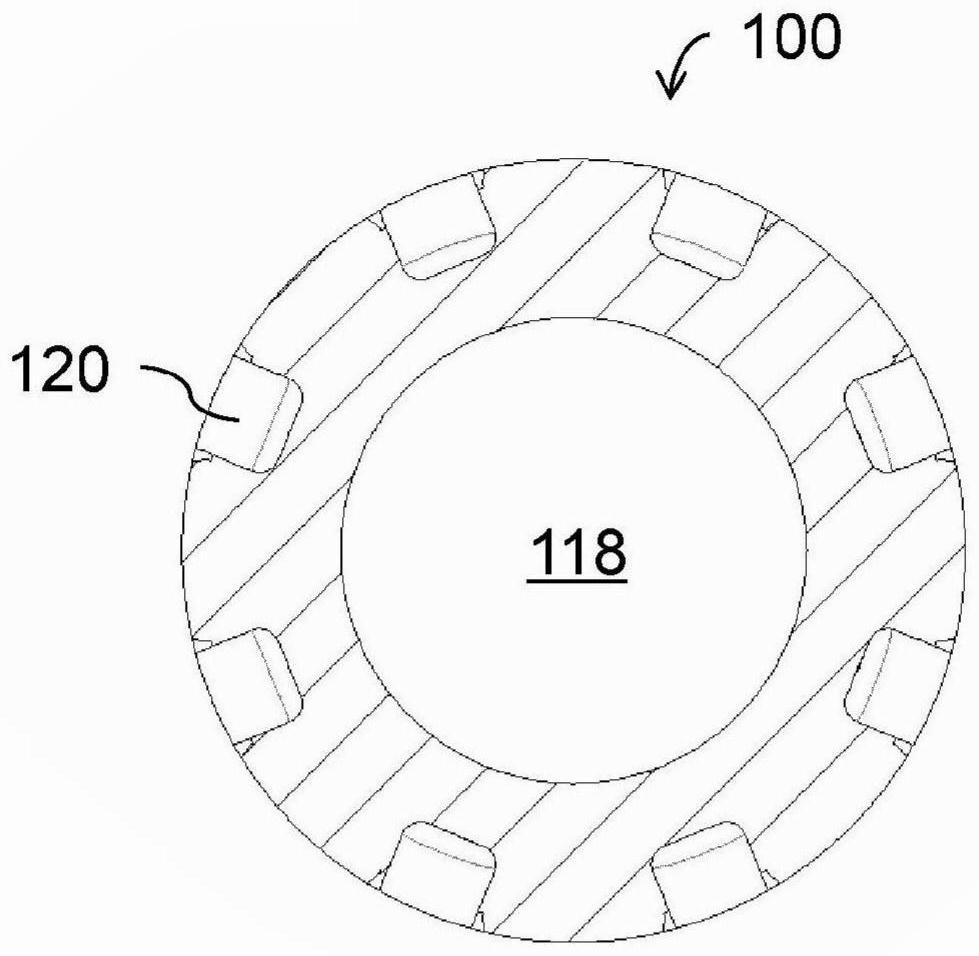

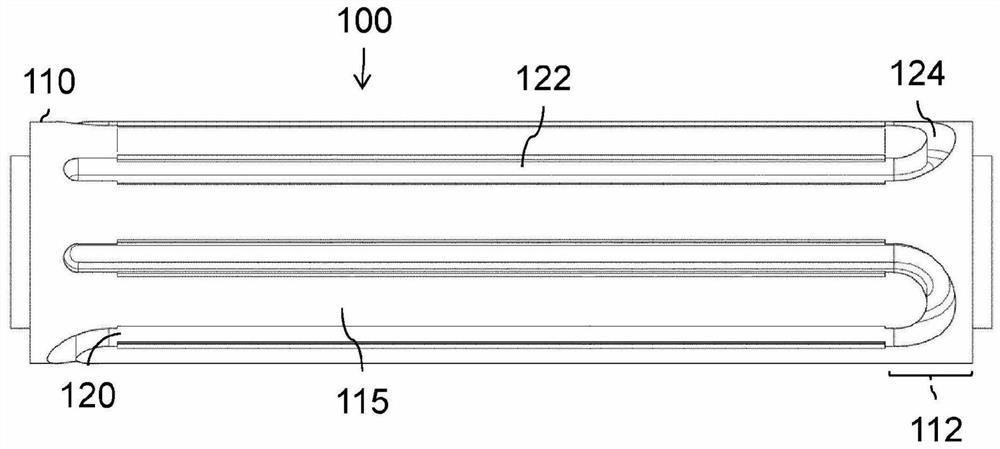

[0038] Figures 1A to 1C Various schematic views of extrusion roll 100 are shown. Figure 1A shows an oblique view, Figure 1B shows a cross-section of the extrusion drum 100, and Figure 1C A side view of the extrusion drum 100 is shown.

[0039] The extrusion drum 100 essentially consists of a drum body 110, preferably made of metal, which is designed as a hollow drum. The drum body 110 has an outer wall 115 corresponding to the outer shell surface of the hollow drum. Inside the drum body 110 is provided an inner space 118 for accommodating the extruder screw, suitable for guiding, plasticizing and mixing extrudates, such as rubber, raw rubber, and the like.

[0040] The dimensions of the extrusion drum 100 here correspond to the dimensions usually used for extrusion and depend essentially on the substance to be extruded. Typical dimensions for the overall length of the extrusion drum for rubber extrusion are approximately in the range of 1 to 5 metres, ie for example ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com