Reciprocation-swing type seed breeding and discharging device of discharge plate

A technology of reciprocating swing and seed metering device, applied in the direction of planter parts, etc., can solve the problems of changes in seed varieties and seed specifications, reducing the operating efficiency of equipment, and tedious operation of seed metering trays, so as to achieve high operation utilization and easy adjustment. Convenience and reliable work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

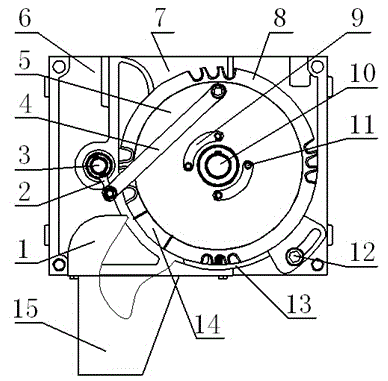

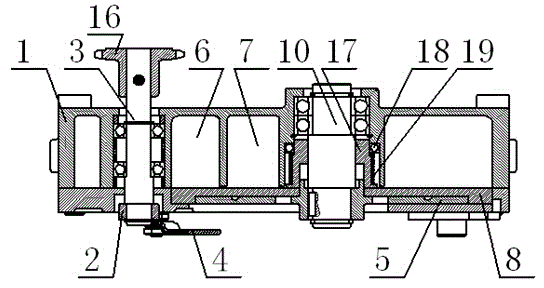

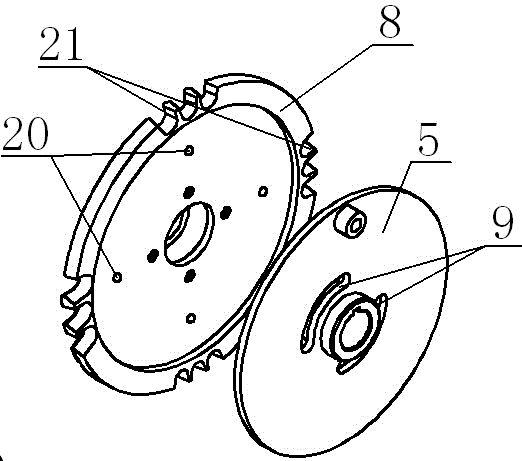

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of reciprocating swing type breeding seed metering device with a seed metering device. A driving shaft 3 and a supporting shaft 10 are rotatably and parallel to each other on the seed metering device housing assembly 1. The driving shaft 3 is located in the seed metering device housing In the seeding chamber 6 of the assembly 1, the support shaft 10 is located in the seed filling chamber 7 of the seed meter housing assembly 1; on both ends of the drive shaft 3, located in the seed meter housing The sprocket 16 and the crank 2 are respectively fixed on the outer part of the assembly 1, and the seeding hole 14 and the seed introduction tube are provided on the lower side of the seed metering device housing assembly 1, which is located at the lower part of the seeding chamber 6 15. On the support shaft 10, the set that can rotate in the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com