Method for preparing mesophase pitch by extracting coal direct liquefaction residue with supercritical solvent

A technology of direct coal liquefaction and mesophase pitch, which is applied in the field of coal deep processing, can solve the problems of unreachable utilization, etc., and achieve the effects of high aromatic carbon rate, improved economic benefits, and low content of quinoline insolubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

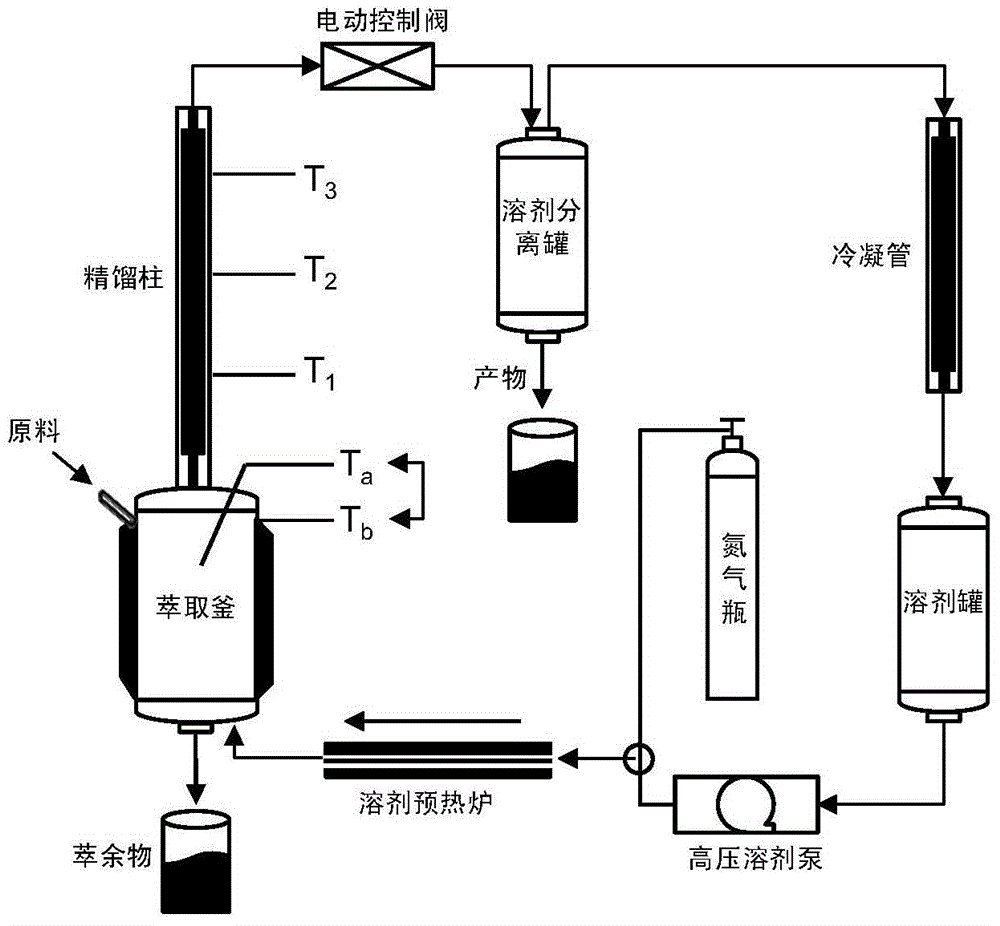

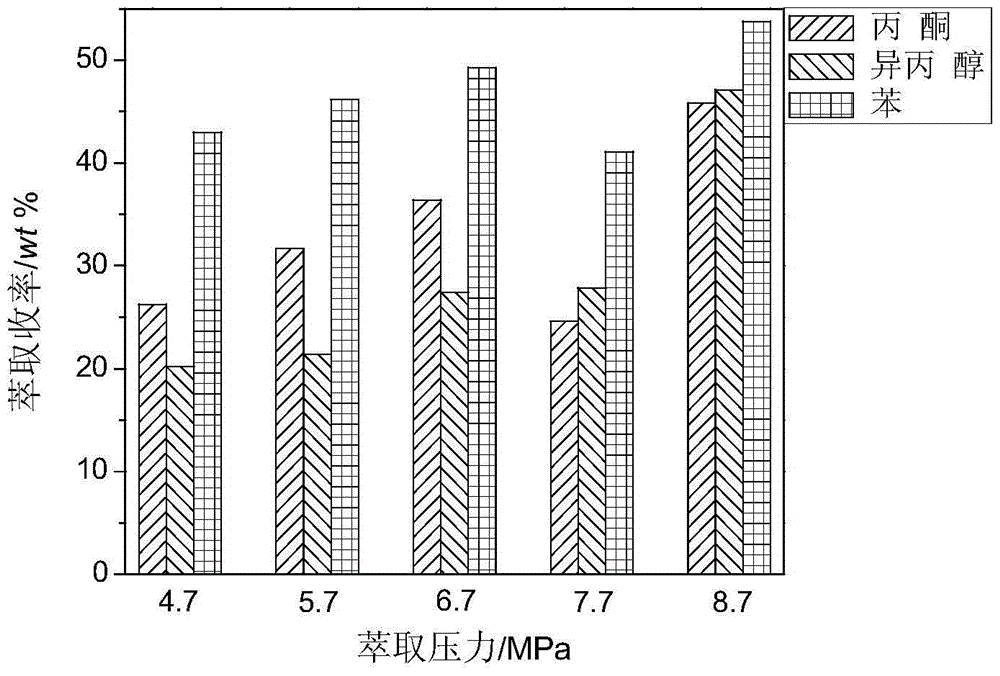

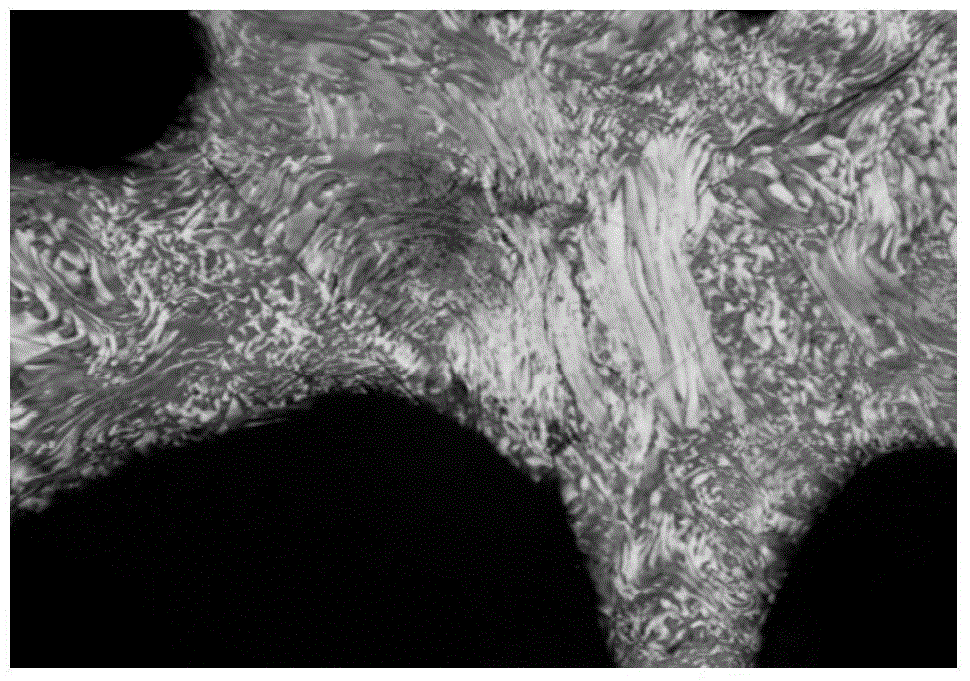

[0038] a) Put 30g of coal direct liquefaction residue into the high-pressure extraction device, and heat the system to 290°C; b) Continuously inject benzene preheated to 290°C into the extraction kettle to raise the internal pressure of the extraction device to 8.7MPa; c) Adjust The electric control valve at the outlet of the extraction device keeps the system pressure stable at 8.7 MPa, and keeps the temperature and pressure state for continuous extraction. The extraction time is 2 hours. During the extraction process, if figure 1 As shown, Ta and Tb are composed of cascade control to ensure that the temperature Ta deviation in the kettle during the extraction process is less than 2°C; the temperature control deviations of T1, T2, and T3 sections are all within ±1°C; the pressure deviation during the entire extraction process is less than 0.1 MPa; d) Put the extracted product in a vacuum drying oven to further remove the residual solvent to obtain mesophase pitch. After testin...

Embodiment 2

[0040] The preparation process of this example is the same as that of Example 1, except that acetone is used as the extraction solvent instead of benzene, and the extraction temperature is changed to 235°C. After testing, in the mesophase pitch obtained by supercritical acetone extraction, the ash content is 0.05%, and the sulfur content is 0.37%. The quinoline-insoluble content is 7.47%, and the content of quinoline insolubles is 0.27%. After calculation, the yield of mesophase pitch obtained by supercritical acetone extraction is 45.85%.

Embodiment 3

[0042] The preparation process of this example is the same as that of Example 1, except that the extraction solvent is benzene is replaced by isopropanol, and the extraction temperature is 235°C. After testing, in the mesophase pitch obtained by supercritical isopropanol extraction, the ash content is 0.06%, and the sulfur content is 0.19%. The content of tetrahydrofuran insolubles is 4.27%, and the content of quinoline insolubles is 0.64%. After calculation, the yield of mesophase pitch obtained by supercritical isopropanol extraction is 47.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com