Steel pipe butting fastener based on wedge-shaped self-lock pre-tightening

A technology of butt buckle and steel pipe, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of poor safety, low operation efficiency, inconvenient use, etc., and achieve the effect of simple operation, high safety, and prevention of movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

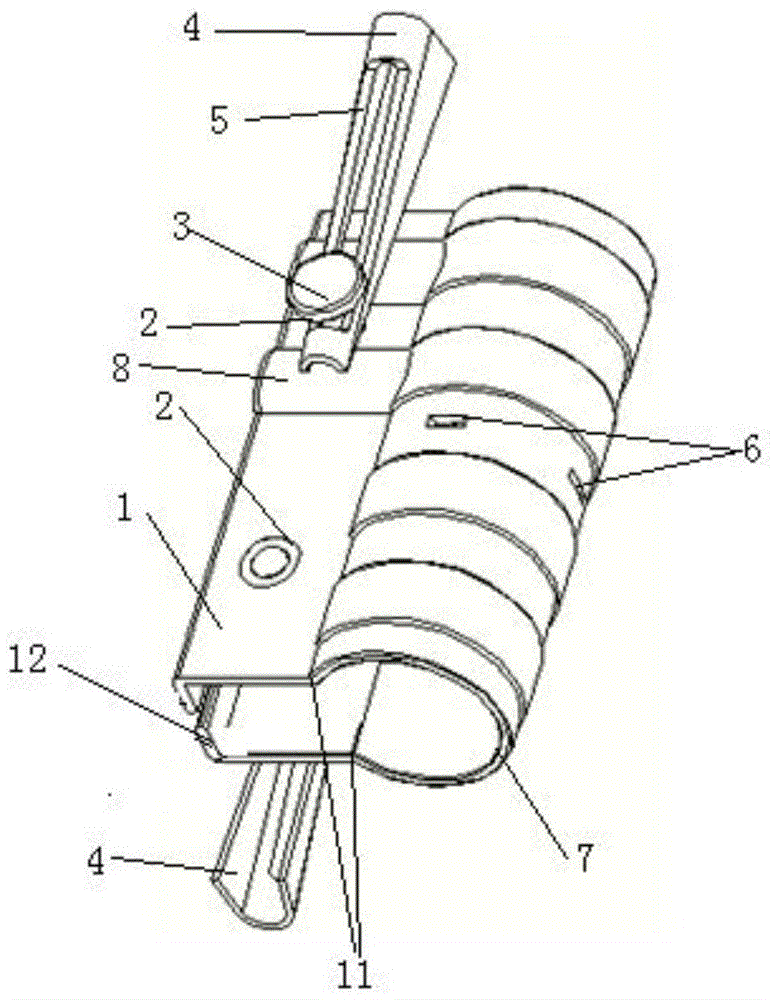

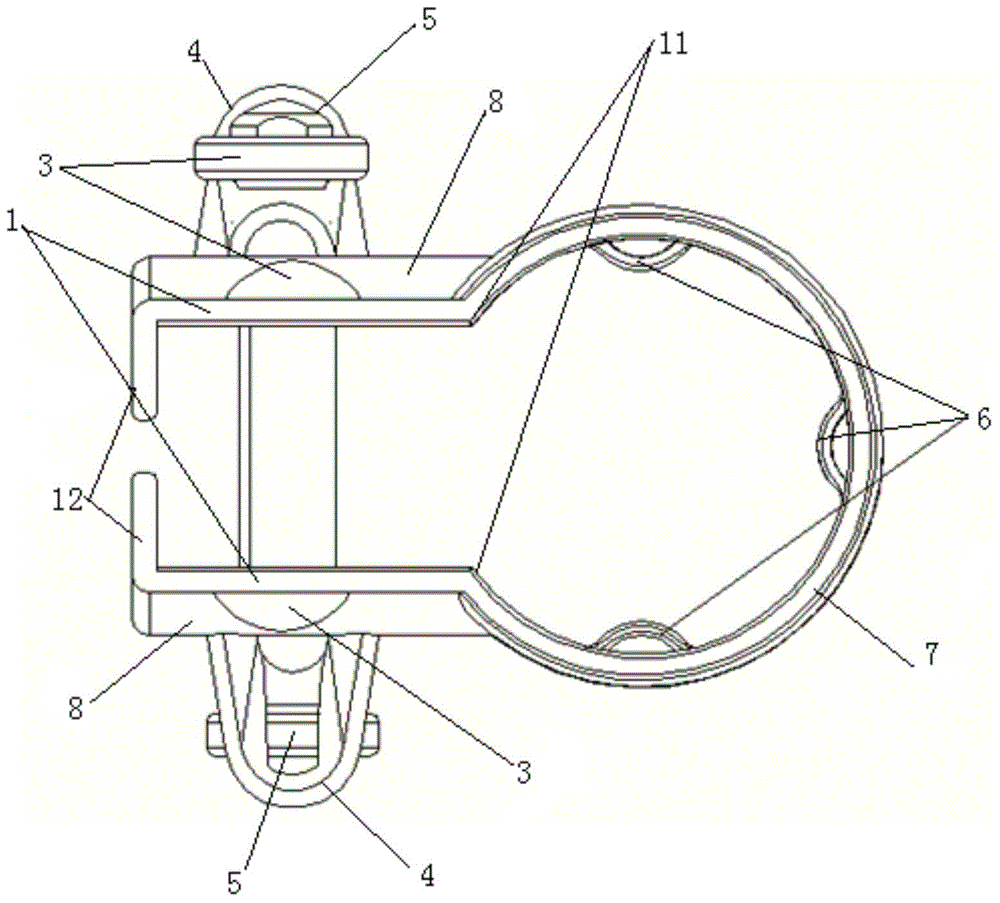

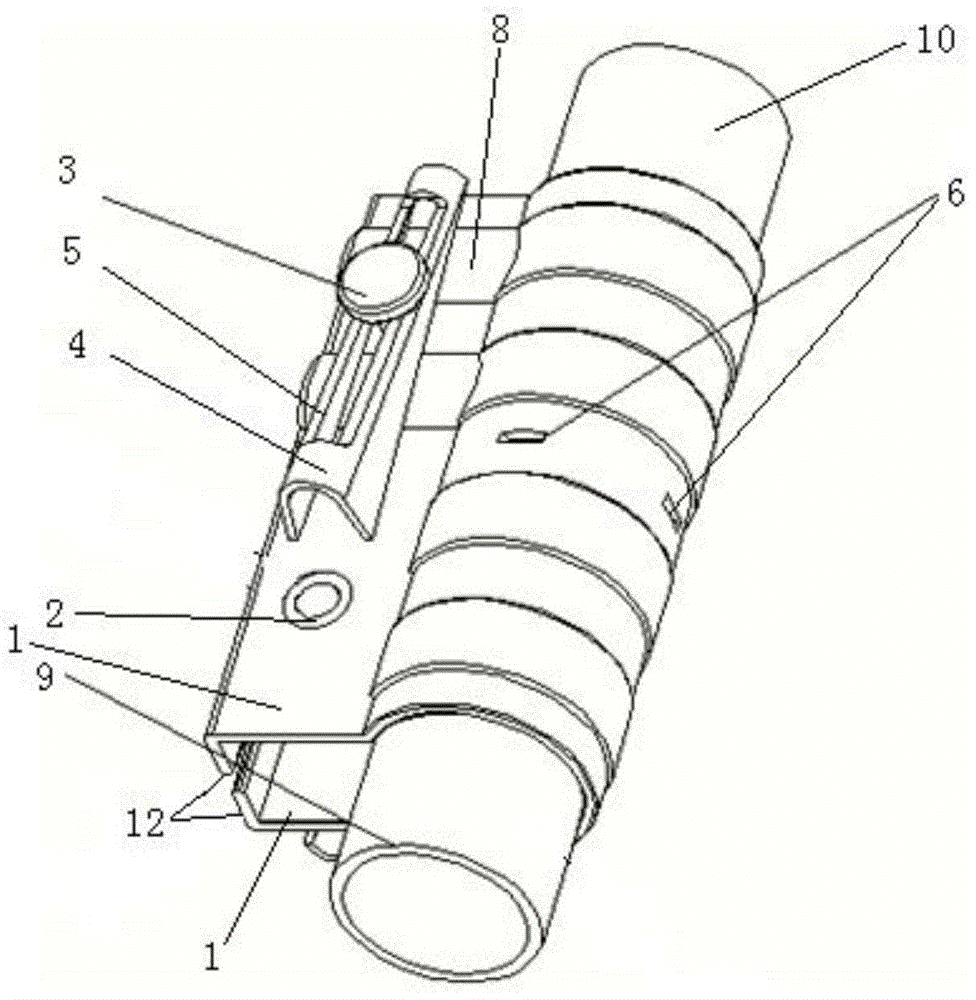

[0017] The present invention is based on wedge-shaped self-locking pre-tightened steel pipe butt fasteners, such as figure 1 , 2 As shown, including the steel pipe socket part and the steel pipe fastening part.

[0018] The steel pipe sleeve part includes a steel cylinder 7, the inner cylinder wall in the middle of the steel cylinder 7 is provided with several shoulders 6 along the circumference, and the cylinder body of the steel cylinder 7 is provided with an opening 11 in the axial direction, and the opening 11 is connected to the steel pipe fastening part .

[0019] The shoulders 6 are arc-shaped protrusions arranged inside the steel cylinder 7, the number of the shoulders 6 is greater than two, and the pipe fittings that can be socketed in the steel cylinder 7 are more reliable.

[0020] The fastening part of the steel pipe includes a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap